Soviet Shermans: The USSR Was a Big Sherman User, and They Liked it

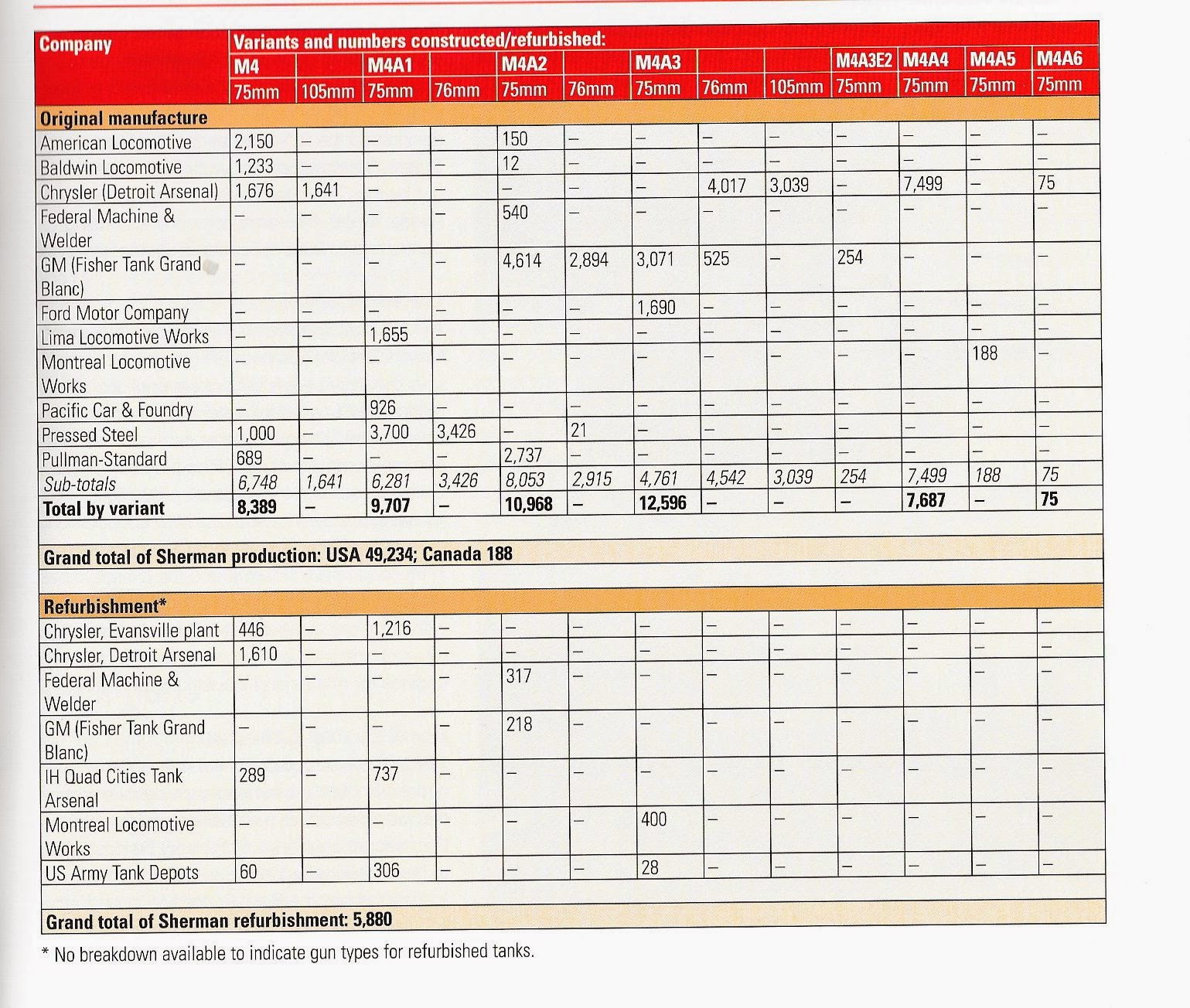

The Soviet Union received three American Medium tank types in large numbers. They received the Lee, and M4A2 75 and 76 tanks. Only the UK would use more M4A2 tanks, though they received only five armed with the 76mm gun, they got far more of the 75mm armed M4A2s. The Soviets also received a pair of M4A4 tanks for evaluation but rejected them because of the motor. My impression from the things I’ve read says, they liked the all of them, well not the A4, but liked the Shermans more than the Lee.

Now let’s cover each tank model.

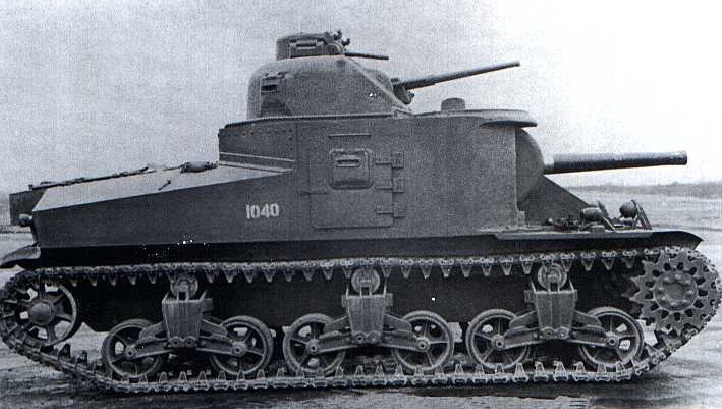

M3 Lee: The Basic Lee

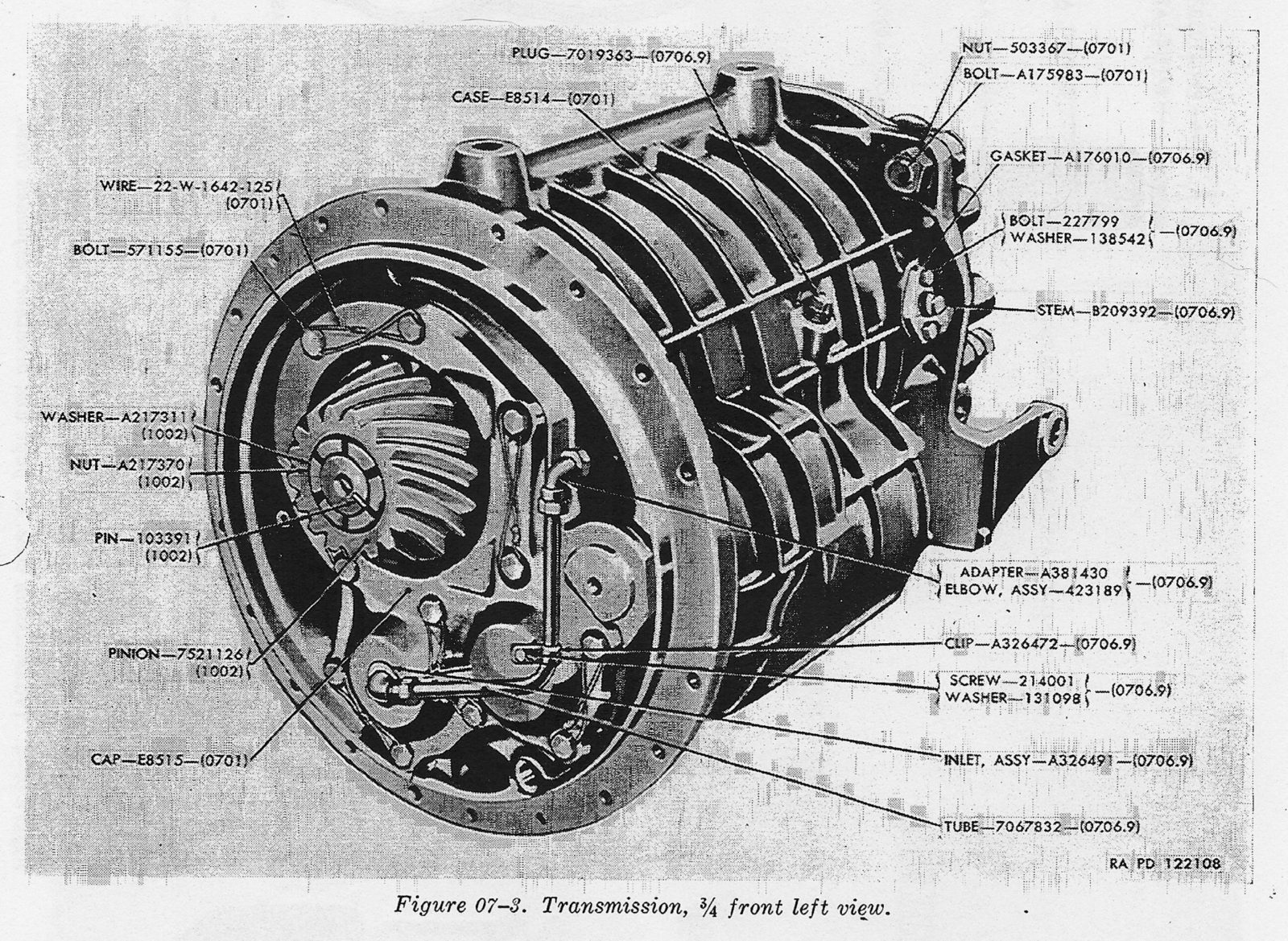

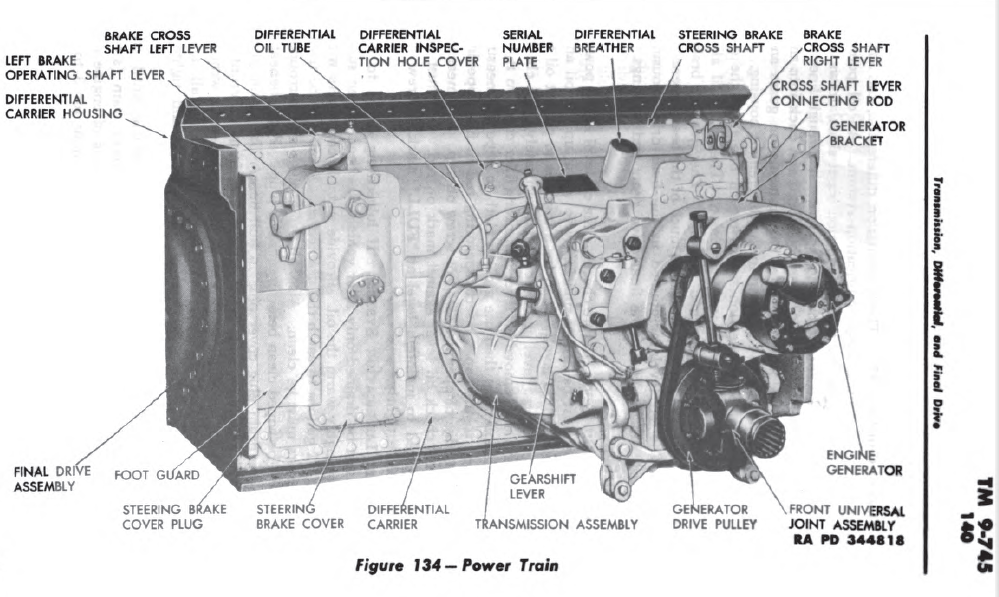

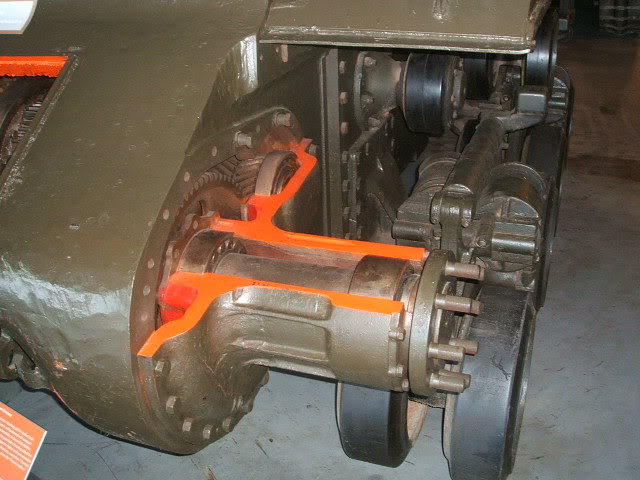

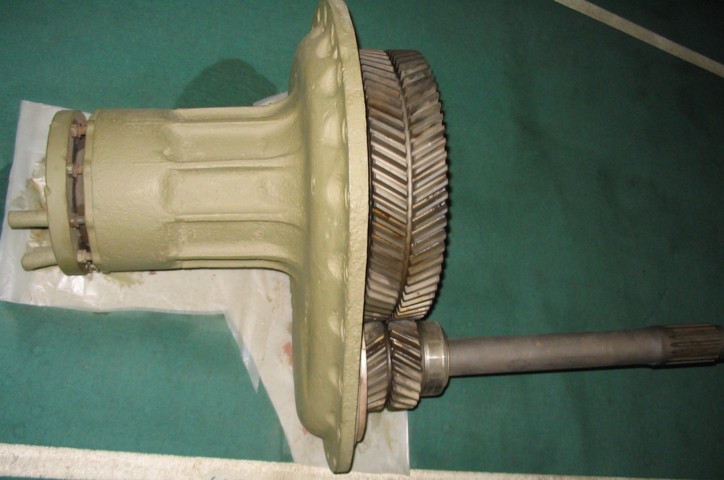

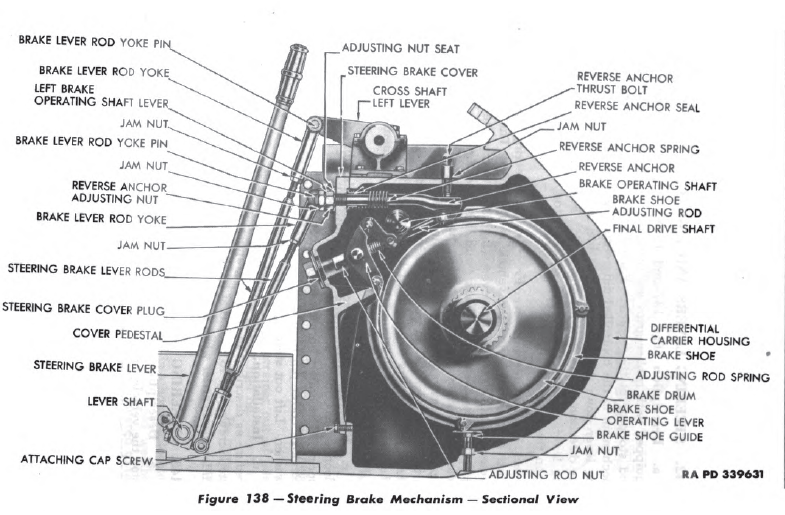

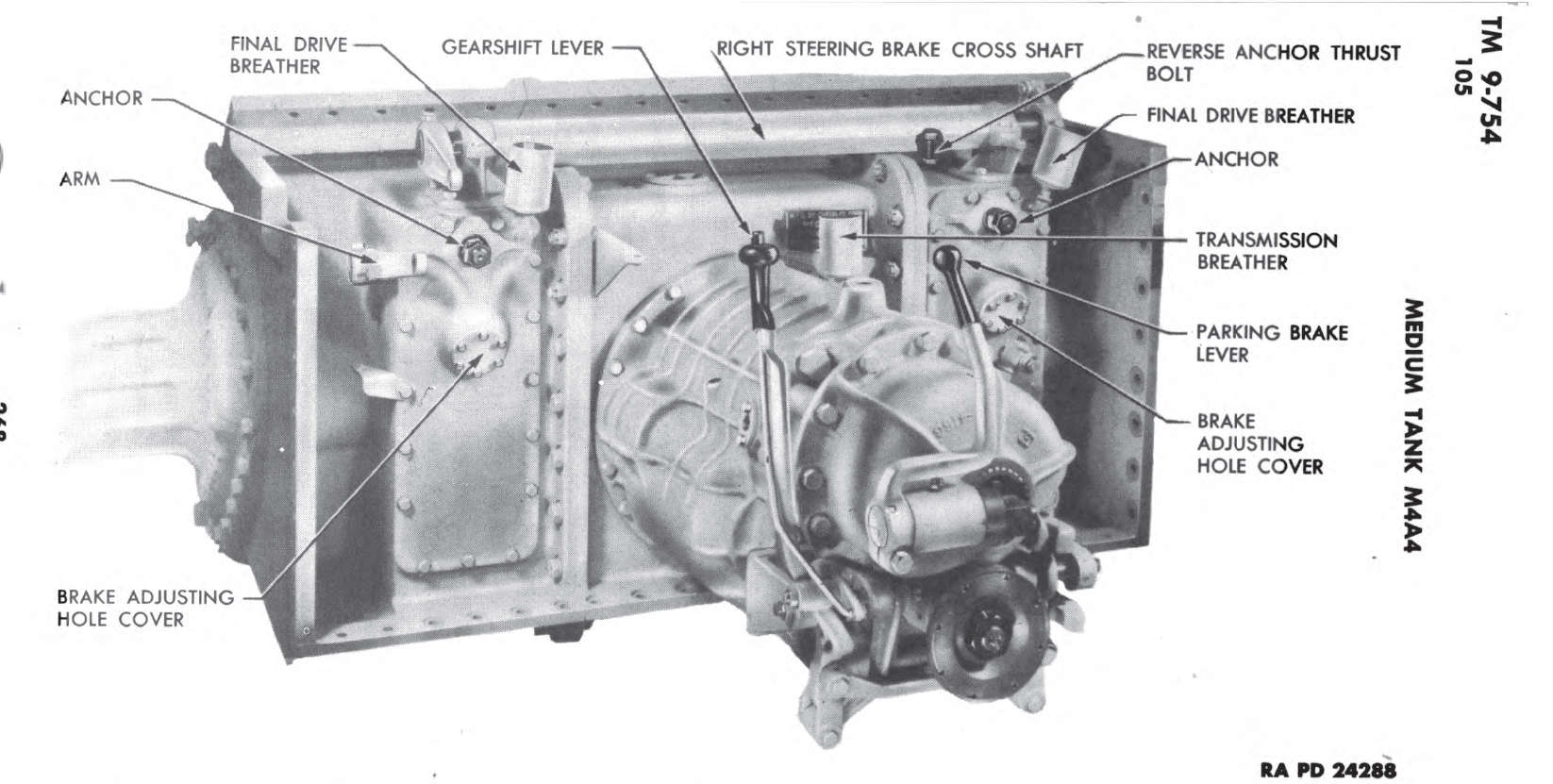

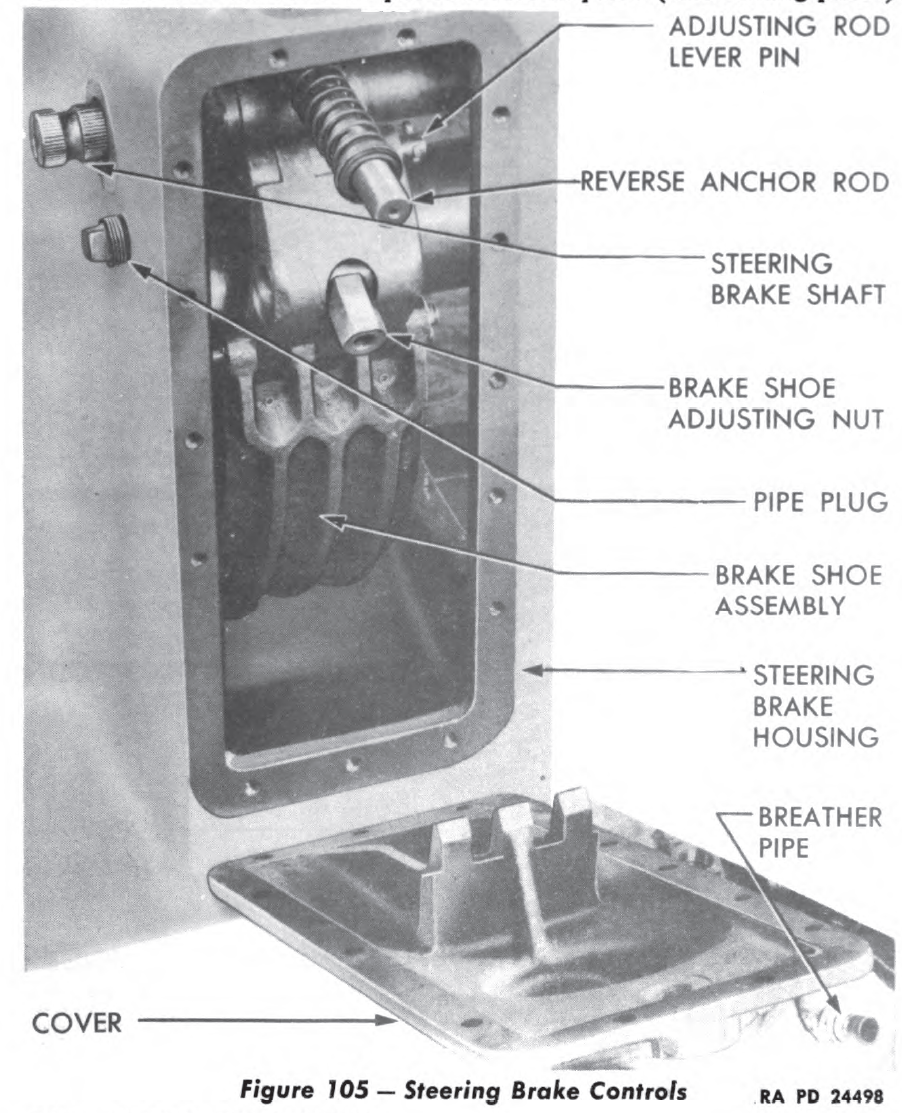

The Lee was not considered a very good design by the Soviet Union, you can read their evaluation here, on Archive Awareness, but it was not all negative. They liked the transmission, differential and final drives, and in particular the steering and brake mechanism. They felt the R975 air-cooled motor was not a great fit for tanks, for all the reasons they are not fit for tanks, mainly the size limitations they put on the tank, and as gasoline AC engines, they don’t have good low-end torque, make driving harder. They disliked the position of the 75mm gun, and lack of sites on the machine guns.

One thing I found very interesting, is in the summer, they could pack up to 10 SMG infantry into the Lee, along with the regular 7 man crew, making it into a makeshift APC. The thing would be packed full of people though. The report says all weapons could be fired on the tank while those 10 men were stuffed in, so I guess the US Army or Brits didn’t try this because they liked comfort or something.

The Lee did not fare well against the upgraded Panzer IV with long 75, and they lost a lot of them, but they never stopped using them, they just did what the British did and sent them off to secondary theaters, where tanks were still useful, and no enemy tanks were around. Against poorly equipped, in AT weapon, Infantry, the M3 Lee was a monster of a tank. The 75mm had a great HE round, it was packed with machine guns, and had a 37mm that could sling canister. The Soviets received 1386 M3 Lee tanks.

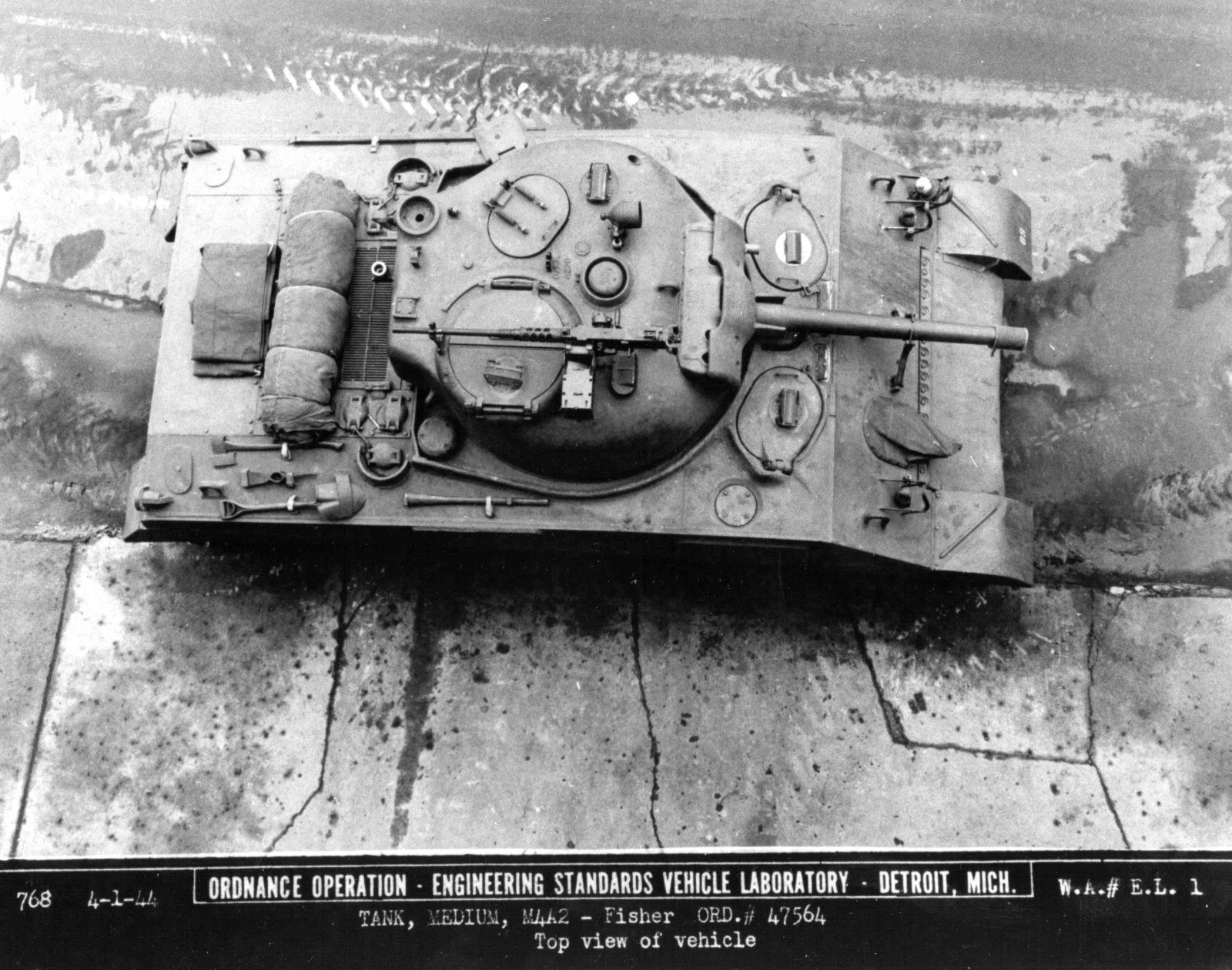

M4A2 75 dry: Early Small Hatch 75mm Shermans with Drivers Hoods

The Soviets received 1990 M3 75mm gun armed M4A2 Shermans. I don’t have a list of who made the early M4A2 tanks they got. They were competing with the Marine Corps and the French and Brits on priority for these tanks, and most went to the Brits. I’ve looked through a lot of pictures of Soviet M4 tanks, or “Emcha” as they seemed to call them, the small hatch 75 tanks seem rarer than the large hatch 75 and 76 tanks.

This Post on Archive Awareness indicates, they received several hundred very early M4A2 tanks. One of the big indicators of this is the section where they talk about the suspension having the Lee style top mounted return roller, which could be jammed with mud, but then they received later models, where this return roller was moved to bracket mounted to the side of the suspension unit.

Another interesting part of that document is the problems they had with injectors and lubrication problems with the pistons. The Army reported similar problems with early model M4A2s, with the Air cleaners, cooling system, and clutches, but nothing about the injectors. This post on AA also indicates injector issues but was overall positive on the M4A2. Maybe the Soviets used low-quality diesel and the injectors didn’t like it. At any rate, these issues would have been worked out by the time they started getting improved models.

M4A2 large hatch Dry: Late Model 75mm, 47-degree Large Hatch Hulls, but with Dry Ammo Racks

By late 1943 a new version of the M4A2 was going into production, and it had the improved 47-degree, single piece front armor plate, with large driver and co-drivers hatches. These would be the first tanks to get this improvement. By the time this model went into production, priority for diesel-powered Shermans was going to the Soviets, since that was the only model they wanted, and the Brits would take the M4A4.

These improved large hatch hulls still used the dry ammunition rack setup of the early small hatch hulls, but they had the applique armor applied at the factory, and the 75mm turrets had an improved casting thickening the area that had required welded on additional armor on the older turrets. The Turrets had a oval loaders hatch and a pistol port as well, though the commander still got the older split hatch cupola with the 50 caliber mount built into it.

These tanks seemed to have been photographed much more than the small hatch 75 tanks, but I do not have a lot of photos of either. By the time these tanks were being produced, all the major reliability issues would have been worked out.

M4A2 76W: The Soviets were the Second Biggest User of 76mm Shermans

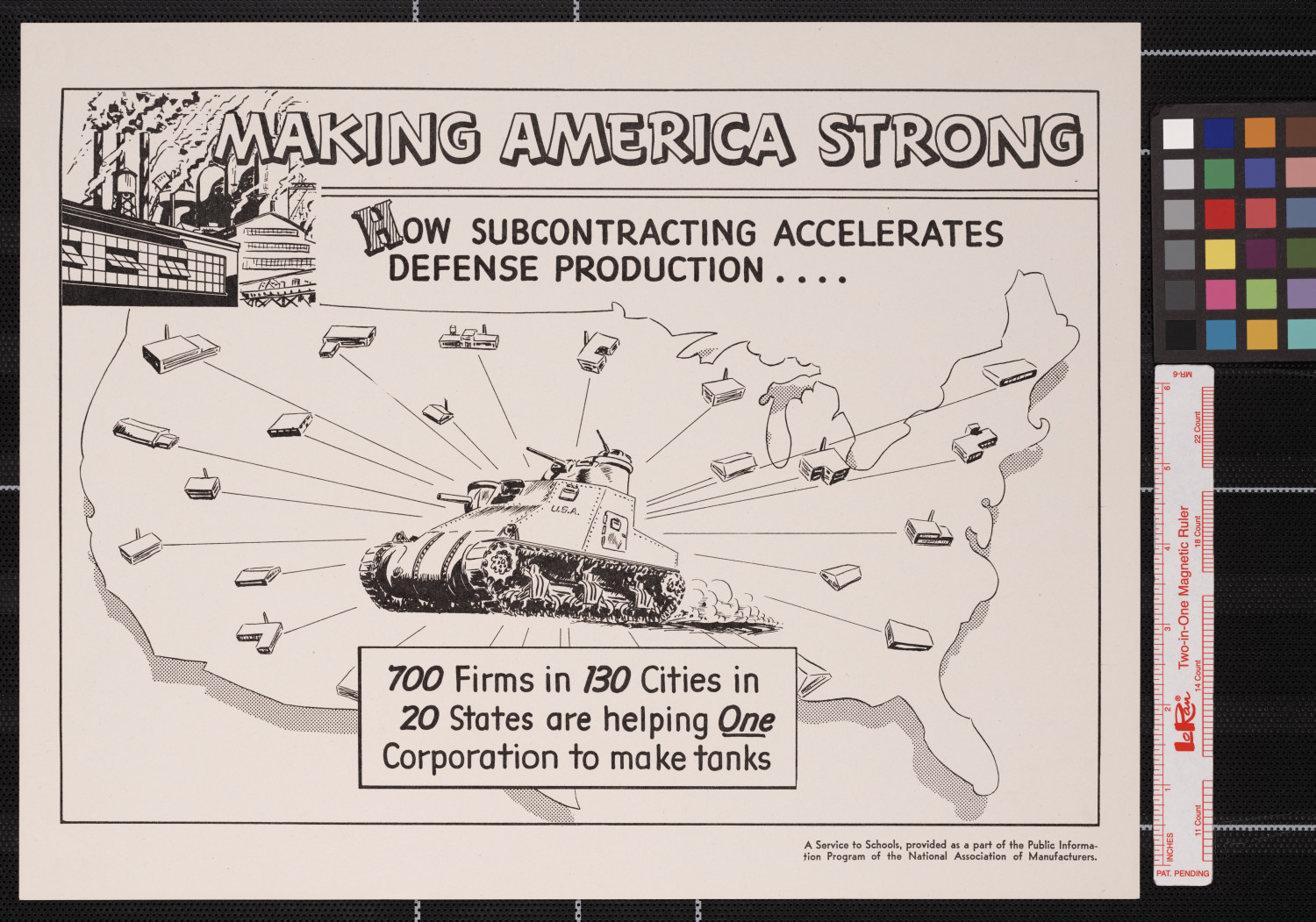

Production of the 75mm armed Sherman was reduced, as Sherman production was streamlined down from the 10 factories that were producing it, to the three that would finish it off, Fisher, Chrysler, and Pressed Steel Car. The Soviet Union received 2073 M4A2 tanks with the 76mm M1A1 gun. This was just about Fishers whole production run on the 76mm armed M4A2.

These tanks would have started out with wet racks, all around vision cupolas, a split loaders hatch and an M1A1 76mm gun without a barrel threaded for a muzzle brake. A few may have even had T23 turrets without the ventilator on the rear. These would quickly be replaced with M1A1C guns with threaded barrels with a protective cap over the threads, and the split loaders hatch would be replaced with the smaller oval hatch. These tanks would eventually be produced in the “Ultimate” configuration, with the M1A2 gun, and HVSS suspension.

These thanks saw extensive combat use with the Soviet Union, use with Guards units. My understanding is the Russians liked the M4A2 76w tanks just fine, and used them in elite units, but this has no reflection on their feelings about the tank compared to their own T-34-85 tanks. T-34s were used in Guards units as well, and some units had both, as we can see from this AA post. By that point in the war the Sherman and T-34 were pretty close in abilities.

M4A4: They Received Two, and that was Enough to Convince them, They Wanted No More

The Soviets sent a group of officials and engineers to check out the Chrysler Defense Arsenal, to review the world famous tank factories abilities, and the tank they were currently making, the M4A4. This visit took place between December of 42 to February of 43, for more details, see this post on AA.

After being given a chance to drive the M4A4 on the proving grounds and being given lectures and demonstrations of its A57 gas motor, the Soviets decided that the M4A4 was better than the M3 Lee, but inferior to the M4A2 with GM Diesel they were already receiving through lend lease. They decided the factory was impressive, but really not producing a very good tank.

Even though the Soviets showed little interest in the M4A4 tanks, two were sent to them for evaluation anyway. You can read their impressions here, but as before when they tested it in the US, they felt the motor was to complicated to be reliable.

. . .

Here are some quotes from the ‘I remember’ interview of Dmitriy Loza, Hero of the Soviet Union, pertaining to the Emchas.

Dmitriy Fedorovich, on which American tanks did you fight?

On Shermans. We called them “Emchas”, from M4 [in Russian, em chetyrye]. Initially they had the short main gun, and later they began to arrive with the long gun and muzzle brake. On the front slope armor there was a travel lock for securing the barrel during road marches. The main gun was quite long. Overall, this was a good vehicle but, as with any tank, it had its pluses and minuses. When someone says to me that this was a bad tank, I respond, “Excuse me!” One cannot say that this was a bad tank. Bad as compared to what?

Dmitriy Fedorovich, did you have just American tanks in your unit?

Our 6th Guards Tank Army (yes, we had six of them) fought in Ukraine, Romania, Hungary, Czechoslovakia, and Austria. We ended the war for us in Czechoslovakia. Then they rushed us to the Far East and we fought against Japan. I briefly remind you that the army consisted of two corps: 5th Guards Tank Stalingrad Corps on our own T-34s and 5th Mechanized Corps, in which I fought. For the first time this corps had British Matildas, Valentines, and Churchills.

They delivered the Churchill later.

Yes, a bit later. After 1943 we largely declined British tanks because they had significant deficiencies. In particular, they had 12-14 h.p. per ton of weight at a time when good tanks had 18-20 h.p. per ton. Of these three British tanks, the best was the Valentine produced in Canada. Its armor was streamlined but more importantly, it featured a long-barreled 57mm main gun. My unit switched over to American Shermans at the end of 1943. After the Kishinev Operation our corps became the 9th Guards Mechanized Corps. I missed to tell you that every corps consisted of four brigades. Our mechanized corps had three mechanized brigades and one tank brigade, in which I fought. A tank corps had three tank brigades and one mechanized brigade. Yes, we had Shermans in our brigade at the end of 1943.

But the British tanks were not withdrawn from service, so they fought until they were gone. Wasn’t there a period when your corps had a mixture of tanks, both American and British? Were there any problems associated with the presence of such a broad variety of vehicles from different countries? For example, with supply and maintenance?

Well, there were always problems. In general, the Matilda was an unbelievably worthless tank! I will tell you about one of the Matilda’s deficiencies that caused us a great deal of trouble. Some fool in the General Staff planned an operation and sent our corps to the area of Yelnya, Smolensk, and Roslavl. The terrain there was forested swamp. The Matilda had skirts along the sides. The tank was developed primarily for operations in the desert. These skirts worked well in the desert-the sand passed through the rectangular slots in them. But in the forested swamps of Russia the mud packed into the space between the tracks and these side skirts. The Matilda transmission had a servomechanism for ease of shifting. In our conditions this component was weak, constantly overheated, and then failed. This was fine for the British. By 1943 they had developed a replacement unit that could be installed simply by unscrewing four mounting bolts, pulling out the old unit, and installing the new unit. It did not always work this way for us. In my battalion we had Senior Sergeant (Starshina) Nesterov, a former kolkhoz tractor driver (Kolkhoz is sort of farm – Valeri), in the position of battalion mechanic. In general each of our tank companies had a mechanic and Nesterov was it for the battalion. At our corps level we had a representative (whose name I have forgotten) of the British firm that produced these tanks. At one time I had it written down, but when my tank was hit everything I had in it burned up -photographs, documents, and notebook. We were forbidden to keep notes at the front, but I did it on the sly. Anyway, this British representative constantly interfered with our efforts to repair separate components of the tank. He said, “This has a factory seal. You should not tinker with it!” We were supposed to take out a component and install a new one. Nesterov made a simple repair to all these transmissions. One time the British representative came up to Nesterov and asked him, “At which university did you study?” And Nesterov replied, “At the kolkhoz!”

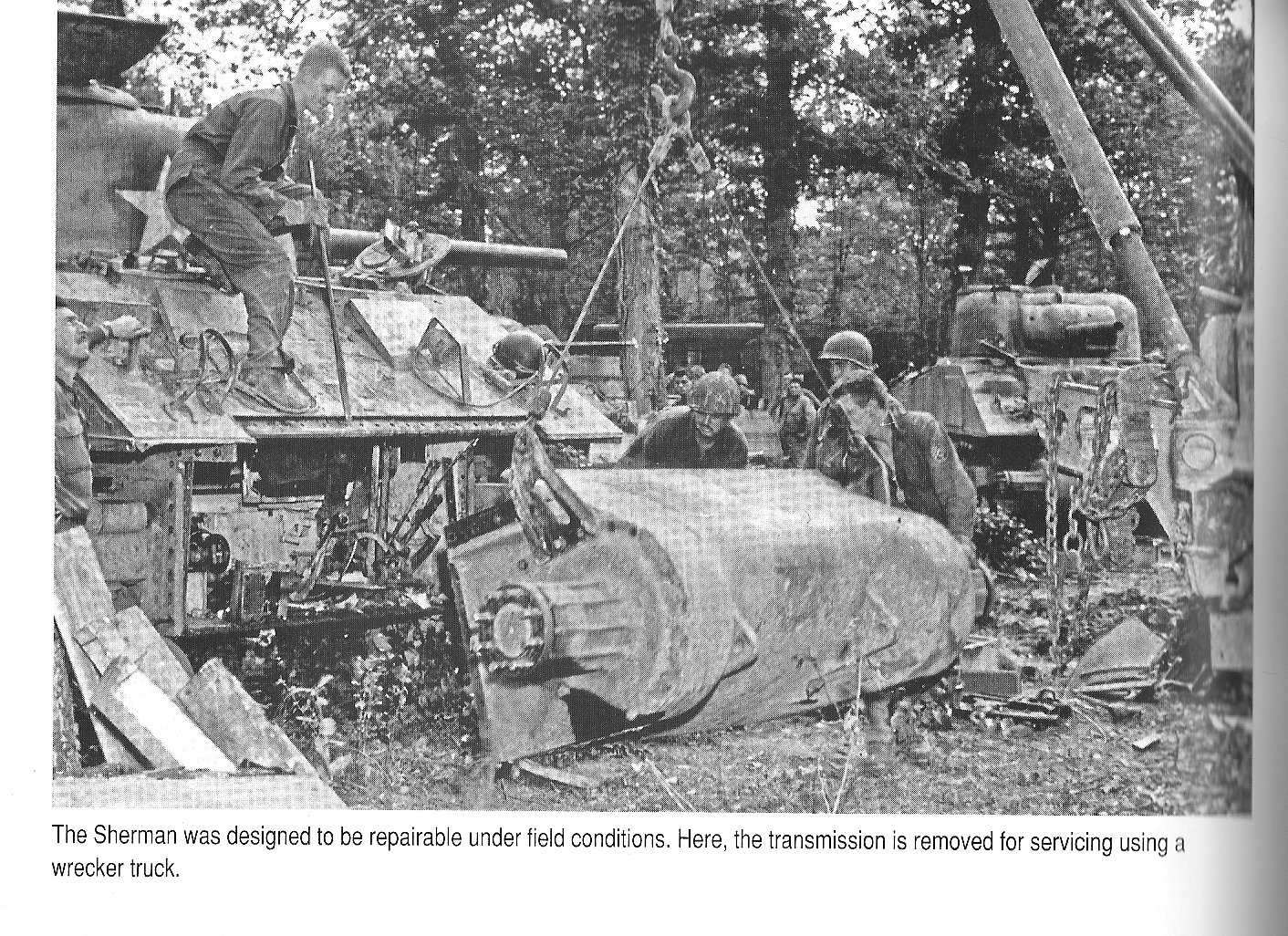

The Sherman was light years better in this regard. Did you know that one of the designers of the Sherman was a Russian engineer named Timoshenko? He was some shirt tail relative of Marshal S. K. Timoshenko.

The Sherman had its weaknesses, the greatest of which was its high center of gravity. The tank frequently tipped over on its side, like a Matryoshka doll (a wooden stacking doll). But I am alive today thanks to this deficiency. We were fighting in Hungary in December 1944. I was leading the battalion and on a turn my driver-mechanic clipped a curb. My tank went over on its side. We were thrown around, of course, but we survived the experience. Meanwhile the other four of my tanks went ahead and drove into an ambush. They were all destroyed.

Dmitriy Fedorovich, the Sherman had a rubber-coated metal track. Some contemporary authors point to this as a deficiency, since in combat the rubber might be set on fire. With the track thus stripped bare, the tank is disabled. What can you say in this regard?

On the one hand this rubber-coated track was a big plus. In the first place, this track had a service life approximately twice that of steel track. I might be mistaken, but I believe that the service life of the T-34 track was 2500 kilometers. The service life of the Sherman track was in excess of 5000 kilometers. Secondly, The Sherman drove like a car on hard surfaces, and our T-34 made so much noise that only the devil knows how many kilometers away it could be heard. What was the bad side of the Sherman track? In my book, Commanding the Red Army’s Sherman Tanks, there is a chapter entitled “Barefooted”. There I wrote about an incident that occurred in August 1944 in Romania, during the Jassy-Kishinev Operation. The heat was fearsome, somewhere around 30° C. We had driven approximately 100 km along a highway in a single day. The rubber linings on our support rollers got so hot that the rubber separated and peeled off in long pieces. Our corps paused not far from Bucharest. The rubber was flying around, the rollers had begun to jam up, the noise was terrible, and in the end we had been stopped. This was immediately reported to Moscow. Was this some kind of joke, an entire corps had halted? To our surprise, they brought new support rollers to us quickly and we spent three days installing them. I still don’t know where they found so many support rollers in such a short time. There was yet another minus of rubber track. Even on a slightly icy surface the tank slid around like a fat cow. When this happened we had to tie barbed wire around the track or make grousers out of chains or bolts, anything to give us traction. But this was with the first shipment of tanks. Having seen this, the American representative reported to his company and the next shipment of tanks was accompanied by additional track blocks with grousers and spikes. If I recall, there were up to seven blocks for each track, for a total of fourteen per tank. We carried them in our parts bin. In general the American representative worked efficiently. Any deficiency that he observed and reported was quickly and effectively corrected.

One more shortcoming of the Sherman was the construction of the driver’s hatch. The hatch on the first shipment of Shermans was located in the roof of the hull and simply opened upward. Frequently the driver-mechanic opened it and raised his head in order to see better. There were several occasions when during the rotation of the turret the main gun struck this hatch and knocked it into the driver’s head. We had this happen once or twice in my own unit. Later the Americans corrected this deficiency. Now the hatch rose up and simply moved to the side, like on modern tanks.

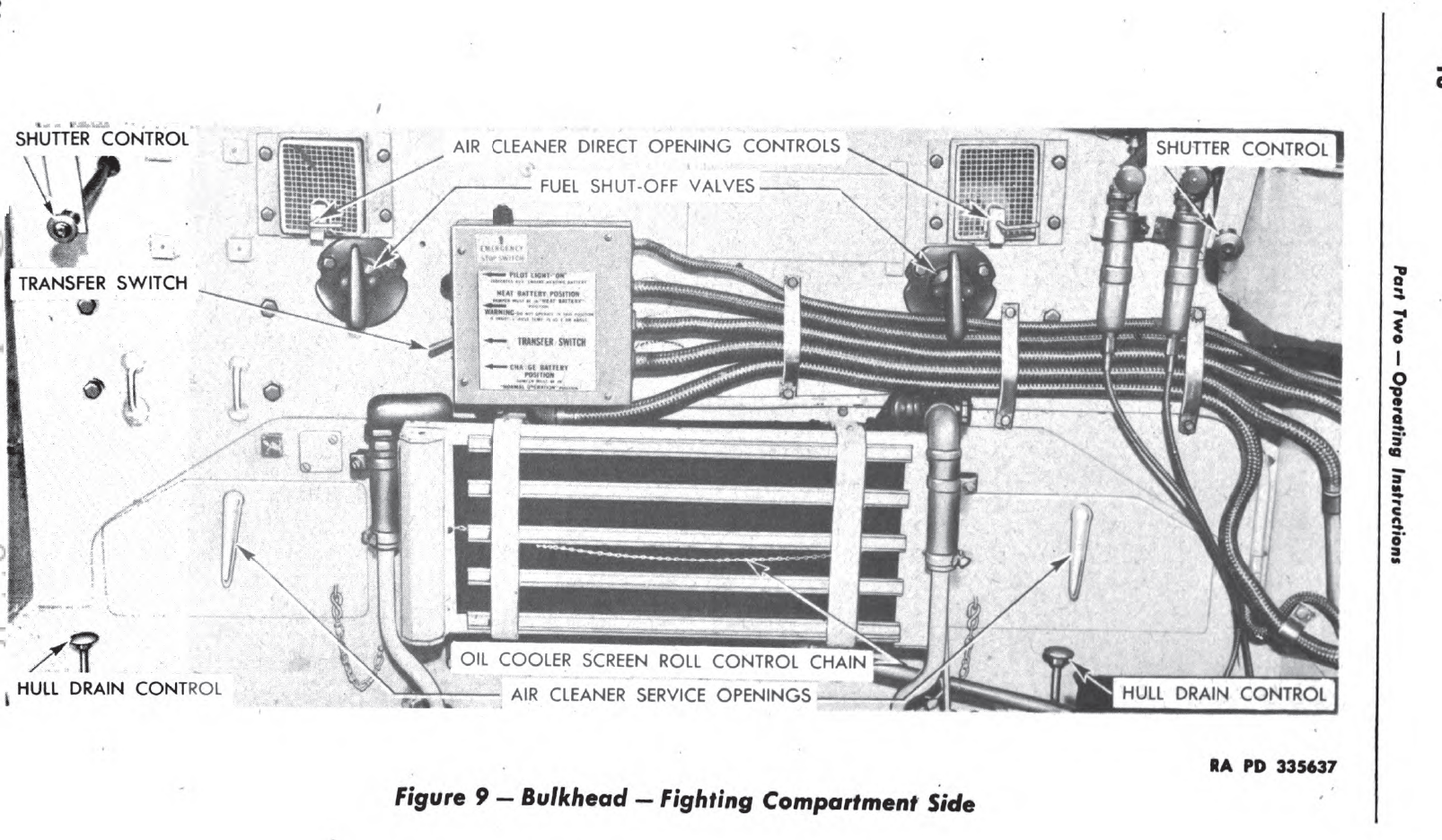

Still one great plus of the Sherman was in the charging of its batteries. On our T-34 it was necessary to run the engine, all 500 horsepower of it, in order to charge batteries. In the crew compartment of the Sherman was an auxiliary gasoline engine, small like a motorcycle’s one. Start it up and it charged the batteries. This was a big deal to us!

For a long time after the war I sought an answer to one question. If a T-34 started burning, we tried to get as far away from it as possible, even though this was forbidden. The on-board ammunition exploded. For a brief period of time, perhaps six weeks, I fought on a T-34 around Smolensk. The commander of one of our companies was hit in his tank. The crew jumped out of the tank but were unable to run away from it because the Germans were pinning them down with machine gun fire. They lay there in the wheat field as the tank burned and blew up. By evening, when the battle had waned, we went to them. I found the company commander lying on the ground with a large piece of armor sticking out of his head. When a Sherman burned, the main gun ammunition did not explode. Why was this?

Such a case occurred once in Ukraine. Our tank was hit. We jumped out of it but the Germans were dropping mortar rounds around us. We lay under the tank as it burned. We laid there a long time with nowhere to go. The Germans were covering the empty field around the tank with machine gun and mortar fires. We lay there. The uniform on my back was beginning heating up from the burning tank. We thought we were finished! We would hear a big bang and it would all be over! A brother’s grave! We heard many loud thumps coming from the turret. This was the armor-piercing rounds being blown out of their cases. Next the fire would reach the high explosive rounds and all hell would break loose! But nothing happened. Why not? Because our high explosive rounds detonated and the American rounds did not? In the end it was because the American ammunition had more refined explosives. Ours was some kind of component that increased the force of the explosion one and one-half times, at the same time increasing the risk of detonation of the ammunition.

It is considered noteworthy that the Sherman was very well appointed on the inside. Was this true?

It was true. These are not just words! They were beautiful! For us then this was something. As they say now, “Euro-repair”! This was some kind of European picture! In the first place, it was painted beautifully. Secondly, the seats were comfortable, covered with some kind of remarkable special artificial leather. If a tank was knocked out or damaged, then if it was left unguarded literally for just several minutes the infantry would strip out all this upholstery. It made excellent boots! Simply beautiful!

In your book “Commanding the Red Army’s Sherman Tanks” you wrote that the 233rd Tank Brigade’s M4A2 Shermans were armed not with the short-barreled 75mm but the long-barreled 76mm main gun in January 1944. Wasn’t this a bit early? Didn’t these tanks appear later? Explain one more time which main guns were mounted on the Shermans of the 233rd Tank Brigade.

Hmm, I don’t know. We had very few Shermans with the short-barreled main gun. On the whole, ours had long-barrels. Not just our brigade fought on Shermans. Perhaps these were in other brigades. Somewhere in the corps I saw such tanks, but we had the tanks with the long barrels.

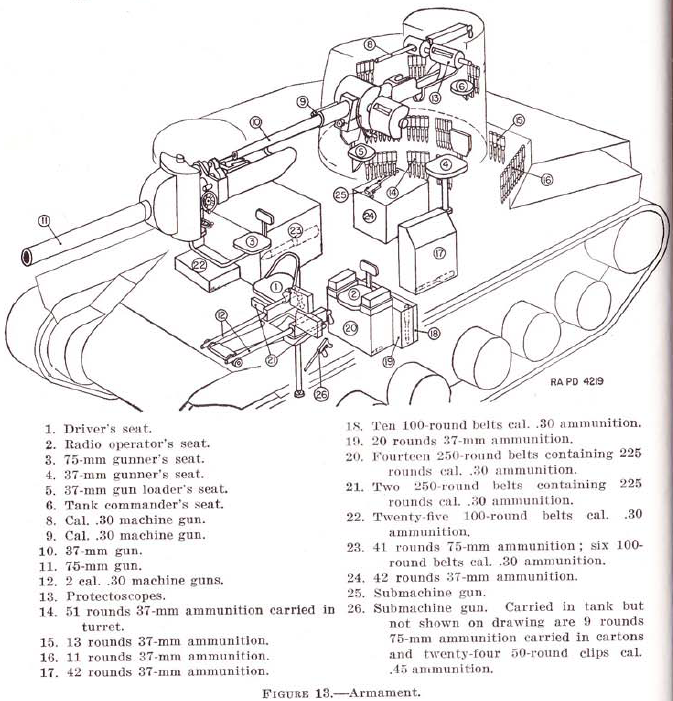

Dmitriy Fedorovich, there were personal weapons in each Sherman that arrived in the USSR, Thompson submachine guns (also known as the Tommy gun). I read that rear area personnel stole these weapons and that few tanks arrived in units still equipped with them. What kind of weapons did you have, American or Soviet?

Each Sherman came with two Thompson submachine guns, in caliber 11.43mm (.45 cal), a healthy cartridge indeed! But the submachine gun was worthless. We had several bad experiences with it. A few of our men who got into an argument were wearing padded jackets. It turned out that they fired at each other and the bullet buried itself in the padded jacket. So much for the worthless submachine gun. Take a German submachine gun with folding stock (MP-40 SMG by Erma -Valeri). We loved it for its compactness. The Thompson was big. You couldn’t turn around in the tank holding it.

The Sherman had an antiaircraft machine gun Browning M2 .50 caliber. Did you use it often?

I don’t know why, but one shipment of tanks arrived with machine guns, and another without them. We used this machine gun against both aircraft and ground targets. We used it less frequently against air targets because the Germans were not fools. They bombed either from altitude or from a steep dive. The machine gun was good to 400-600 meters in the vertical. The Germans would drop their bombs from say, 800 meters or higher. He dropped his bomb and departed quickly. Try to shoot the bastard down! So yes, we used it, but it was not very effective. We even used our main gun against aircraft. We placed the tank on the upslope of a hill and fired. But our general impression of the machine gun was good. These machine guns were of great use to us in the war with Japan, against kamikazes. We fired them so much that they got red hot and began to cook off. To this day I have a piece of shrapnel in my head from an antiaircraft machine gun.

Did German aircraft inflict significant losses on your equipment? In particular, what can you say about the Henschel Hs-129?

Not every time, but it did happen. I don’t remember the Henschel; perhaps there was such an airplane. Sometimes we were able to avoid bombs. You could see them coming at you, you know. We opened our hatches, stuck out our heads, and instructed our drivers over the intercom: “The bomb will fall in front of us”. But in general there were cases when tanks were hit and set on fire. Losses from these attacks did not exceed 3-5 tanks in the battalion. It was more common for a single tank to be damaged or destroyed. We faced much greater danger from panzerfaust gunners in built-up areas. In Hungary I recall that I was so tired that I told my deputy to lead the battalion while I slept. I went to sleep right there in the fighting compartment of my Sherman. Around Beltsy they had dropped ammunition to us by parachute. We took one parachute for ourselves. I used this parachute for my pillow. The parachute was made from silk and didn’t let the lice in. And I was sound asleep! Suddenly I woke up. Why? I awoke from the silence. Why the silence? It turns out that attacking aircraft had set two tanks on fire. During the march many things were piled up on the tanks: crates, tarpaulin. The battalion had halted, shut off engines, and it had become silent. And I woke up.

Did you lock your hatches during combat in built-up areas?

We absolutely locked our hatches from the inside. In my own experience, when we burst into Vienna, they were throwing grenades at us from the upper floors of buildings. I ordered all the tanks to be parked under the archways of buildings and bridges. From time to time I had to pull my tank out into the open to extend a whip antenna and send and receive communications from my higher commander. On one occasion, a radio operator and driver-mechanic were doing something inside their tank and left the hatch open. Someone dropped a grenade through the hatch from above. It struck the back of the radio operator and detonated. Both were killed. Thus we most certainly locked our hatches when we were in built-up areas.

The primary defeating mechanism of HEAT (hollow-charge) ammunition, of which the panzerfaust was one type, is the high pressure in the tank, which disables the crew. If the hatches were kept slightly open, would this not provide some degree of protection? A special order was issued before our forces entered Germany.

This is true, but just the same we kept our hatches locked. It might have been different in other units. The panzerfaust gunners most often fired at the engine compartment. If they were able to set the tank on fire, like it or not the crew had to get out. And then the Germans shot at the crew with a machine gun.

What were the chances of survival if your tank was hit?

My tank was hit on 19 April 1945 in Austria. A Tiger put a round straight through us. The projectile passed through the entire fighting compartment and then the engine compartment. There were three officers in the tank: I as the battalion commander, the company commander Sasha Ionov (whose own tank had already been hit), and the tank commander. Three officers, a driver-mechanic, and a radio operator. When the Tiger hit us, the driver-mechanic was killed outright. My entire left leg was wounded; to my right, Sasha Ionov suffered a traumatic amputation of his right leg. The tank commander was wounded, and below me sat the gunner, Lesha Romashkin. Both of his legs were blown off. A short time before this battle, we were sitting around at a meal and Lesha said to me, “If I lose my legs I will shoot myself. Who will need me?” He was an orphan and had no known relatives. In a strange twist of fate, this is what happened to him. We pulled Sasha out of the tank and then Lesha, and were beginning to assist in the evacuation of the others. At this moment Lesha shot himself.

In general, one or two men were always wounded or killed. It depended where the shell struck.

How did you co-operate with the infantry during combat?

By TOE the tank brigade had three tank battalions of 21 tanks each and a battalion of submachine gunners. A submachine gun battalion had three companies, one for each tank battalion. We had this three-battalion structure only in late 1943 and early 1944. All the rest of the time we had two tank battalions in the brigade. Our submachine gunners were like brothers to us. On the march they sat on our tanks. They kept warm there, dried their things, and slept. We drove along and then stopped somewhere. The tankers could sleep and our submachine gunners protected our tanks and us. Over the course of time many submachine gunners became members of our crews, initially as loaders and later as radio operators. We divided our trophies equally: they with us and we with them. Therefore they had an easier time of it than ordinary infantrymen.

During combat they sat on the tanks until the firing started. As soon as the Germans opened fire on our tanks, they jumped off and ran behind the tanks, frequently protected by its armor from enemy light machine gun fire.

If it happened that the tanks were limited in maneuver and speed, did you maneuver your infantry or halt them?

Nothing like that. We did not pay any attention to them. We maneuvered and they maneuvered themselves behind us. There were no problems. It would have been worse for them if we had been knocked out, so let them run behind us.

Was the tank’s speed limited in the attack? By what?

Of course! We must been fire!

How did you fire, from short halts or on the move?

Both ways. If we fired on the move, the speed of the tank did not exceed 12 km/h. But we rarely fired on the move, only in order to incite panic in the enemy ranks. Primarily we fired from short halts. We rushed into a position, stopped for a second, fired, and moved ahead.

What would you like to say about the German Tiger?

It was an extremely heavy vehicle. The Sherman could never defeat a Tiger with a frontal shot. We had to force the Tiger to expose its flank. If we were defending and the Germans were attacking, we had a special tactic. Two Shermans were designated for each Tiger. The first Sherman fired at the track and broke it. For a brief space of time the heavy vehicle still moved forward on one track, which caused it to turn. At this moment the second Sherman shot it in the side, trying to hit the fuel cell. This is how we did it. One German tank was defeated by two of ours, therefore the victory was credited to both crews. There is a story about this entitled “Hunting With Borzois” in my book.

The muzzle brake has one significant shortcoming: a cloud of dust is raised during firing from a weapon thus equipped, giving away one’s position. Some artillerymen attempted to counter this, for example, by wetting down the ground in front of their cannons. What countermeasures did you employ?

You’re correct! We might have packed the ground and covered it with our tarpaulins. I don’t recall any special problems.

Were your tank sights blinded by dust, dirt, or snow?

There were no special difficulties. Snow, of course, could blind us. But not dust. The sight on the Sherman did not protrude. On the contrary, it was recessed into the turret. Therefore it was well protected against the elements.

Dmitriy Fedorovich, our tankers who fought on the British Churchills pointed out the weak heater in the crew compartment as a deficiency. The standard electric heater was inadequate for the conditions of the Russian winter. How was the Sherman equipped in this regard?

The Sherman had two engines connected by a coupling joint. This was both good and bad. There were cases when one of these motors was disabled in battle. Then the coupling joint could be disengaged from the crew compartment and the tank could crawl away from the fight on one engine. On the other hand, there were powerful fans located above both engines. We used to say, “Open your mouth and the wind came out your ass!” How the hell could we get warm? There were such strong drafts of air! Perhaps there was heat coming from the engines, but I will not tell you that it was warm. When we halted, we immediately covered the engine compartment with our tarpaulin. Then it stayed warm in the tank for several hours; we slept in the tank. Not for nothing did the Americans give us fleece-lined coveralls.

Were there norms of ammunition consumption for the tank?

Yes there were. In the first place, we took one basic load (BK -boekomplekt -a full set of ammo. For example the IS-2’s BK = 28 shells. -Valeri) with us going into battle. We took an additional BK on the outside of our tanks during long raids. When I raced into Vienna, for example, my commander personally ordered us to take two BK: the normal load inside and the second on the armor. In addition, we carried up to two cases of trophy chocolate on each tank and found additional provisions for ourselves. We were “on our own”, so to speak. This meant that if we had to conduct a raid somewhere deep in the rear, we offloaded rations and in their place took ammunition. All of our wheeled supply vehicles were American 2 ?-ton Studebakers. They always brought the ammunition forward to the battalion.

There is one other thing I want to say. How did we preserve our (Soviet) ammunition? Several rounds covered by a thin layer of grease, in wooden crates. One had to sit for hours and clean this grease off the rounds. American ammunition was packed in cardboard tube containers, three rounds banded together. The rounds were shiny clean inside their protective tubes! We took them out and immediately stowed them in the tank.

What kind of rounds did you carry in the tank?

Armor-piercing and high explosive. There was nothing else. The ratio was approximately one-third HE and two-thirds AP.

Did the crew receive a concussion when a round hit the tank, even if it did not penetrate the armor?

Generally, no. It depended on where the round hit. Let’s say that I was sitting in the left side of the turret and a round struck near me. I heard this hit but it did not harm me. If it struck somewhere on the hull, I might not hear it at all. This happened several times. We would come out of an engagement and inspect the tank. In several places the armor would show an impact, like a hot knife that had cut through butter. But I did not hear the round impacts. Sometimes the driver would shout, “They’re shooting from the left!” But there was no overwhelming sound. Of course, if such a powerful gun as the JSU-152 hit you, you heard it! And it would take off your head along with the turret.

I want also to add that the Sherman’s armor was tough. There were cases on our T-34 when a round struck and did not penetrate. But the crew was wounded because pieces of armor flew off the inside wall and struck the crewmen in the hands and eyes. This never happened on the Sherman.

What did you consider the most dangerous opponent? A cannon? A tank? An airplane?

They were all dangerous until the first round was fired. But in general, the antitank cannons were the most dangerous. They were very difficult to distinguish and defeat. The artillerymen dug them in so that their barrels literally were laying on the ground. You could see only several centimeters of their gun shield. The cannon fired. It was a good thing if it had a muzzle brake and dust was kicked up! But if it was winter or raining, what then?

Were there cases when you did not see from your tank where the fire was coming from, but your SMG infantry did see? How did they guide you to the source of the fire?

Sometimes they pounded on the turret and shouted. Sometimes they began to fire in the direction with tracer bullets or fired a signal rocket in that direction. And then, you know, when we went into the attack, the commander often looked around from the turret. None of the periscopes, even in the commander’s cupola, gave us good visibility.

How did you maintain communications with your commander and other tanks?

By radio. The Sherman had two radio sets, HF and UHF [high frequency and ultra high frequency], of very good quality. We used the HF for communications with our higher commander, with brigade, and the UHF for communications within the company and battalion. For conversation inside the tank we used the tank intercom system. It worked great! But as soon as the tank was hit, the tankers first action was to throw off his helmet and throat microphone. If he forgot and began to jump out of the tank, he would get hung up.

For the full interview, click the link and check out the I remember site.