The Chrysler A57 Page

The Chrysler A57 Multibank: The Motor Chrysler Came Up With To Power Tanks, It Was Crazy, And It Worked!

The Chrysler A57 multibank

Type: 30-cylinder, 4 -cycle, multibank

Cooling system: Liquid Ignition: Battery

Displacement: 1253 Cubic Inches (20.5 liters) Bore and stroke: 4.37×4.5 inches Compression Ratio: 6.2:1

Net Horsepower: 370 Gross Horsepower: 425

Net Torque: 1020 ft-lbs Gross Torque: 1060 ft-lbs

Weight: 5400 lbs. dry Fuel: 80 octane gasoline Engine Oil Capacity: 32 Quarts Dimensions, Lenght: 54 1/2 inches Height: 56 1/2 inches Width: 58 3/4 inches

In mid-1941, what do you get when the US Army asks Chrysler to build a tank motor for medium tanks and fast? You get a tank motor so complicated it almost seems German designed. But unlike most German designed things of WWII, the Chrysler Motor, the A-75 Multibank worked. This motor went on to be one of the most reliable power plants the Sherman would use and would best the Motor the US Army chose the R975 in reliability, and driveability.

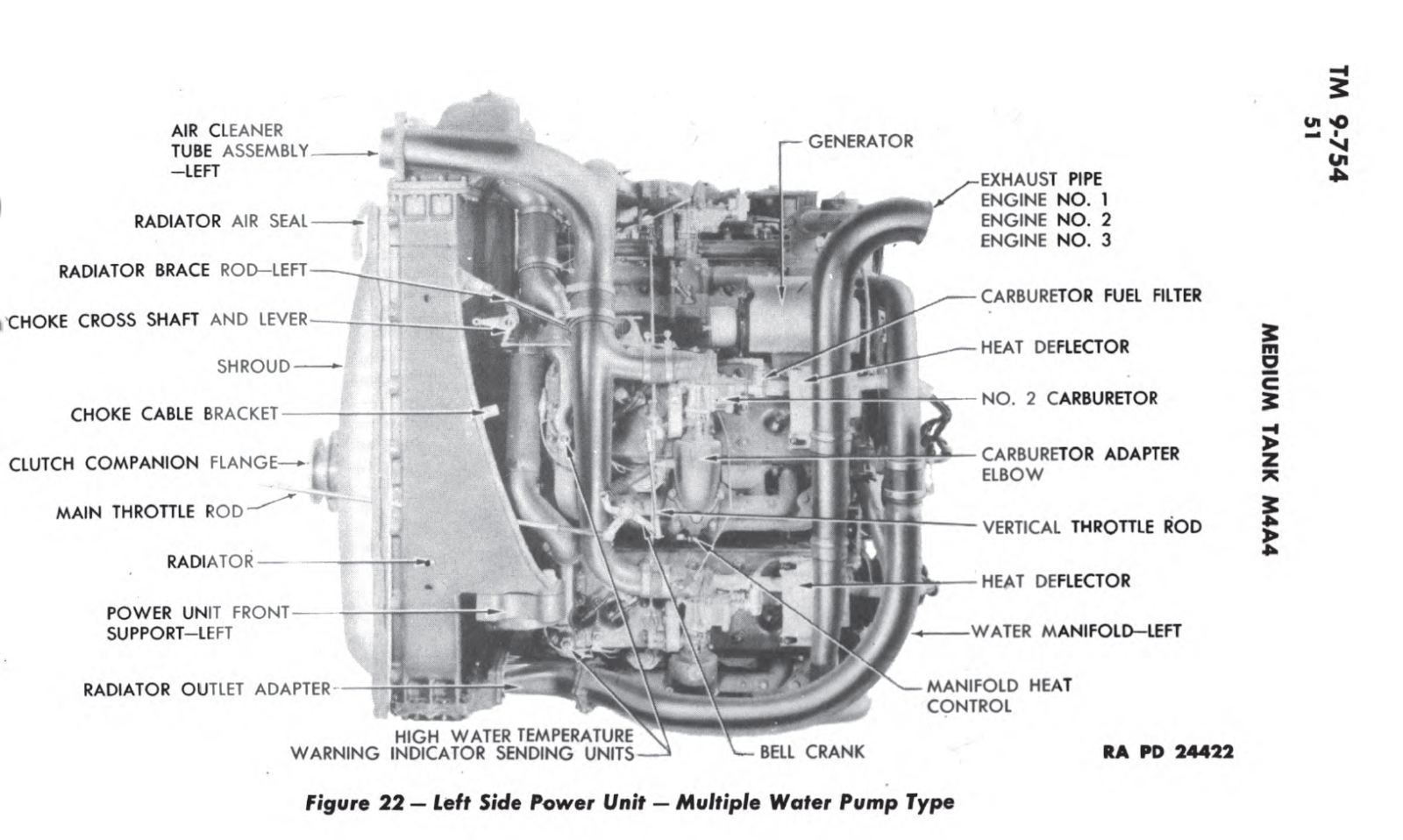

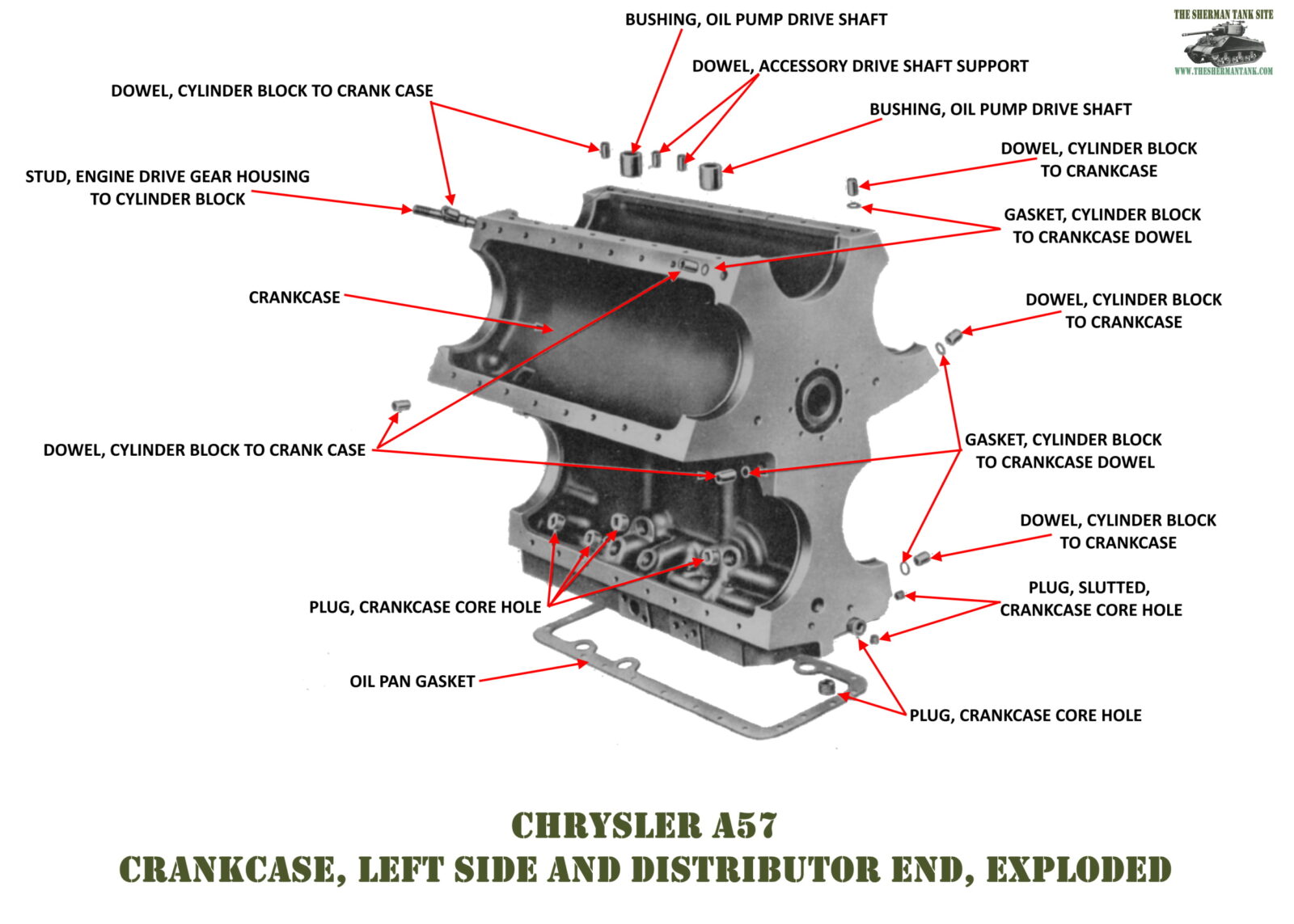

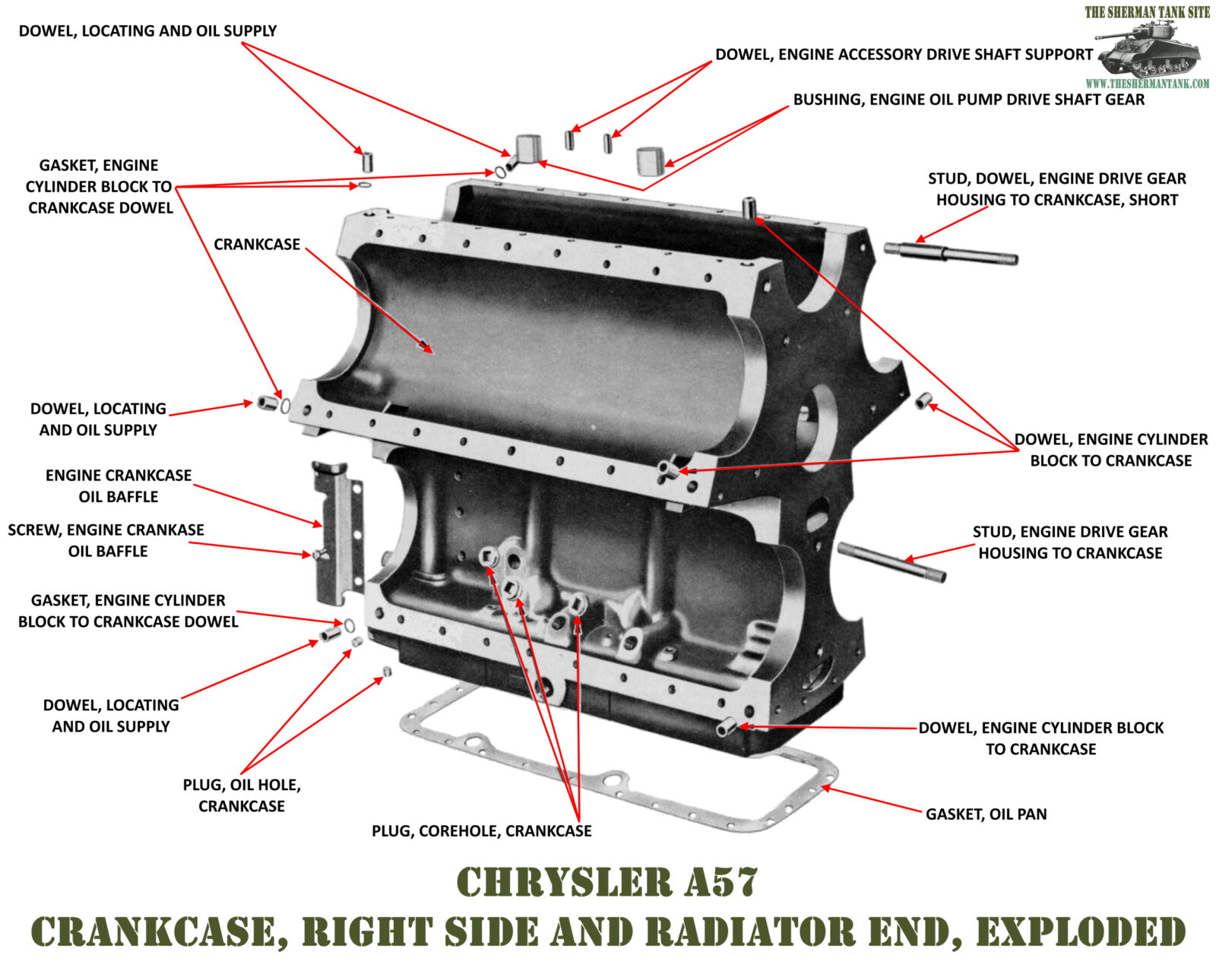

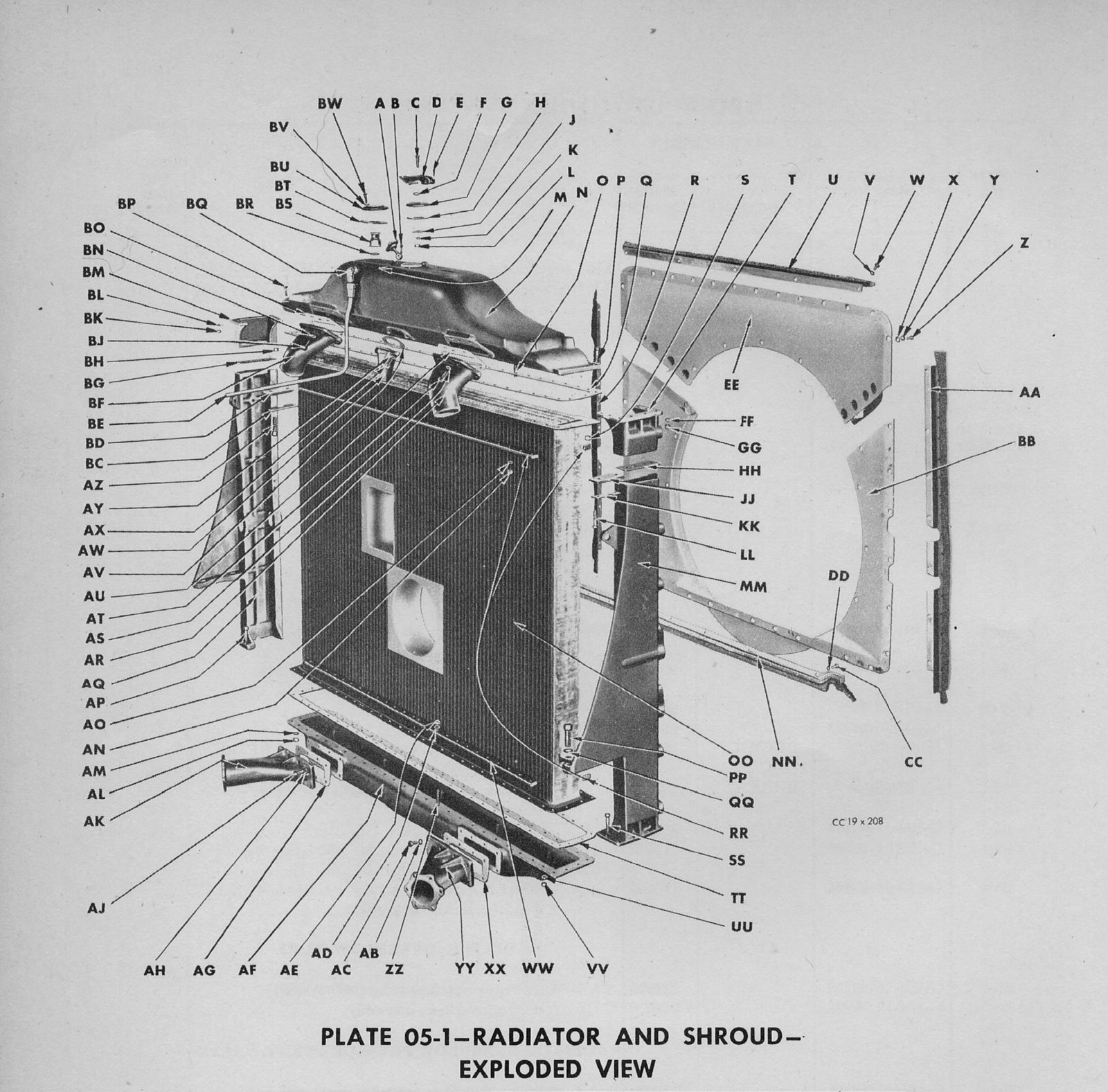

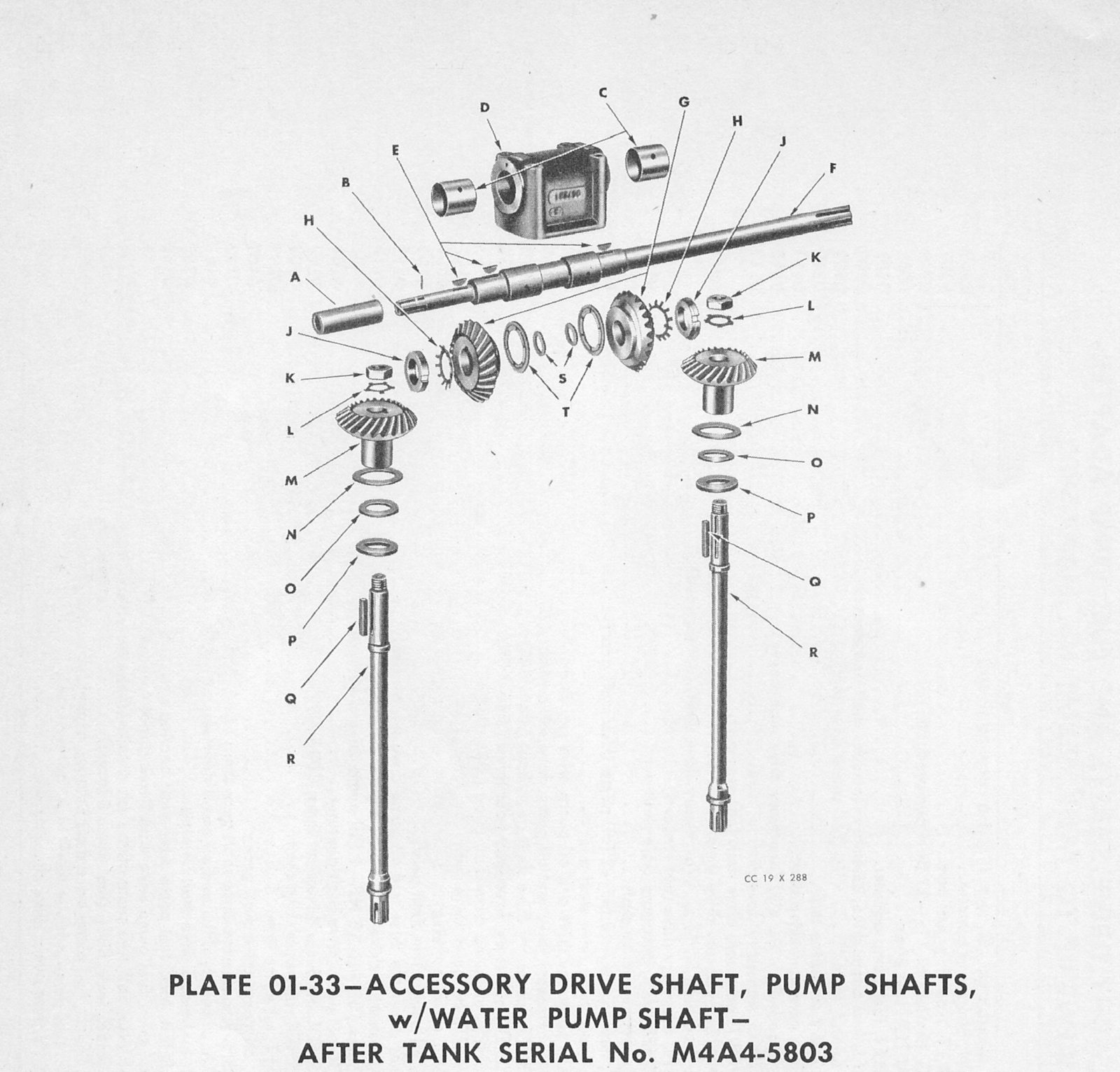

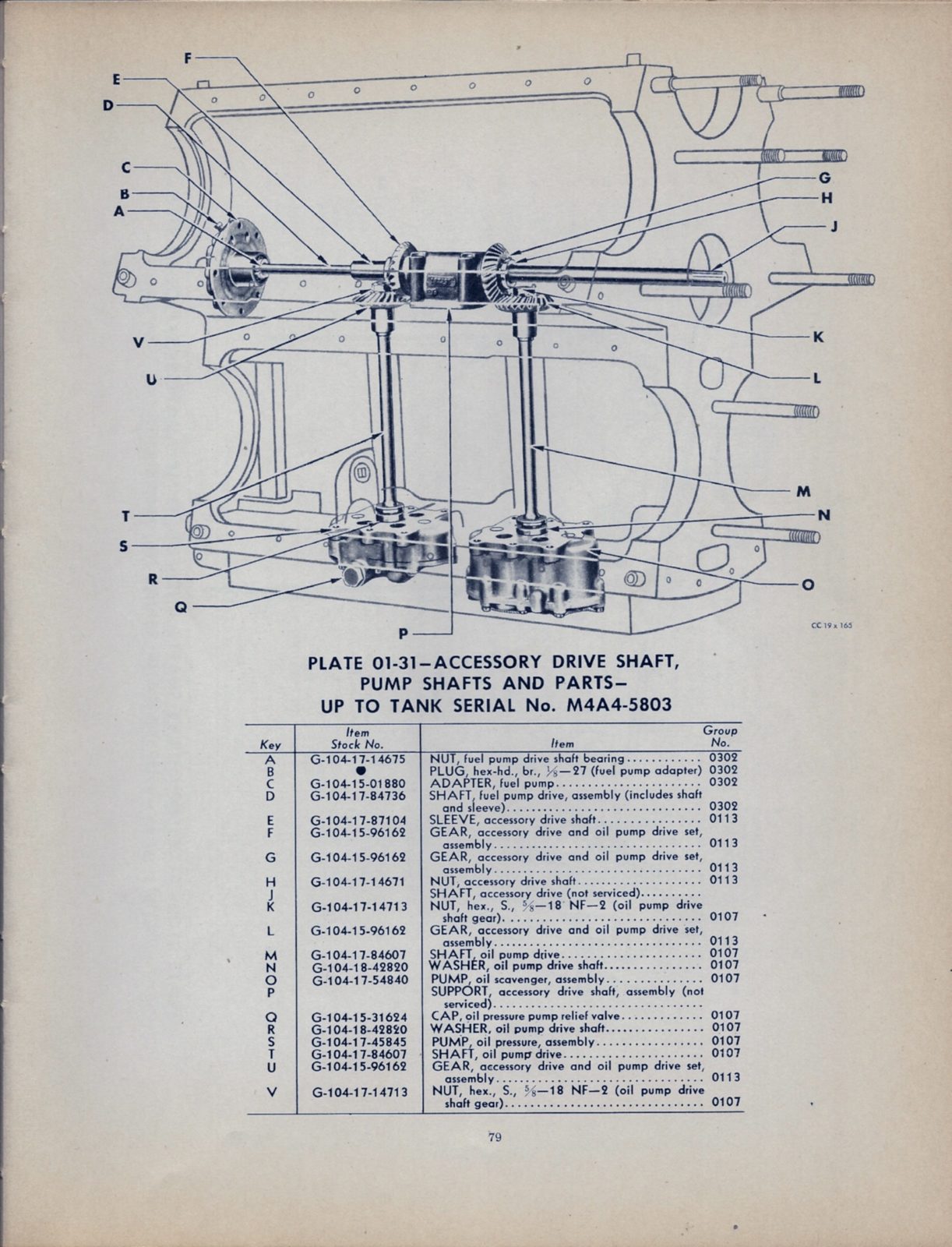

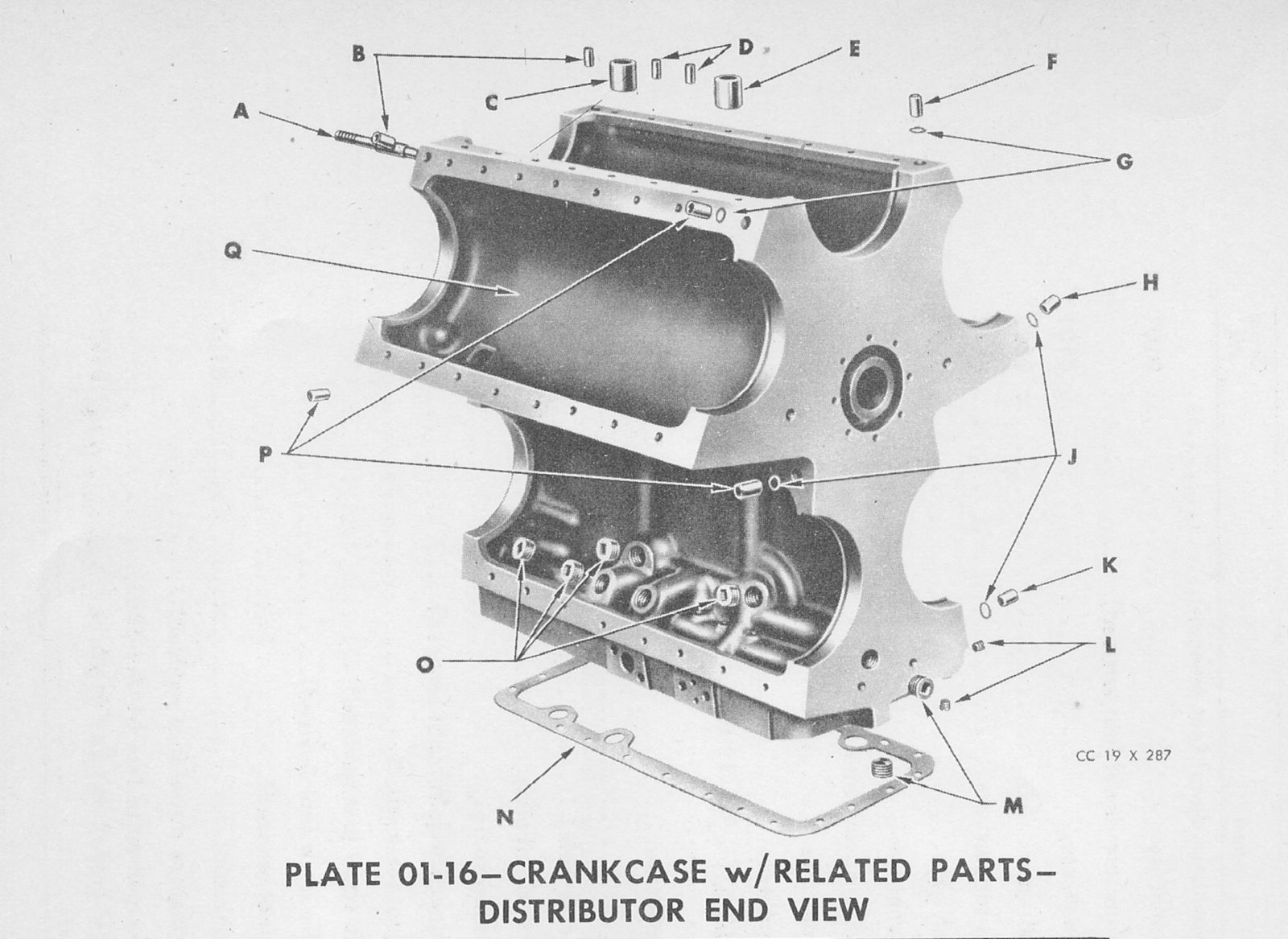

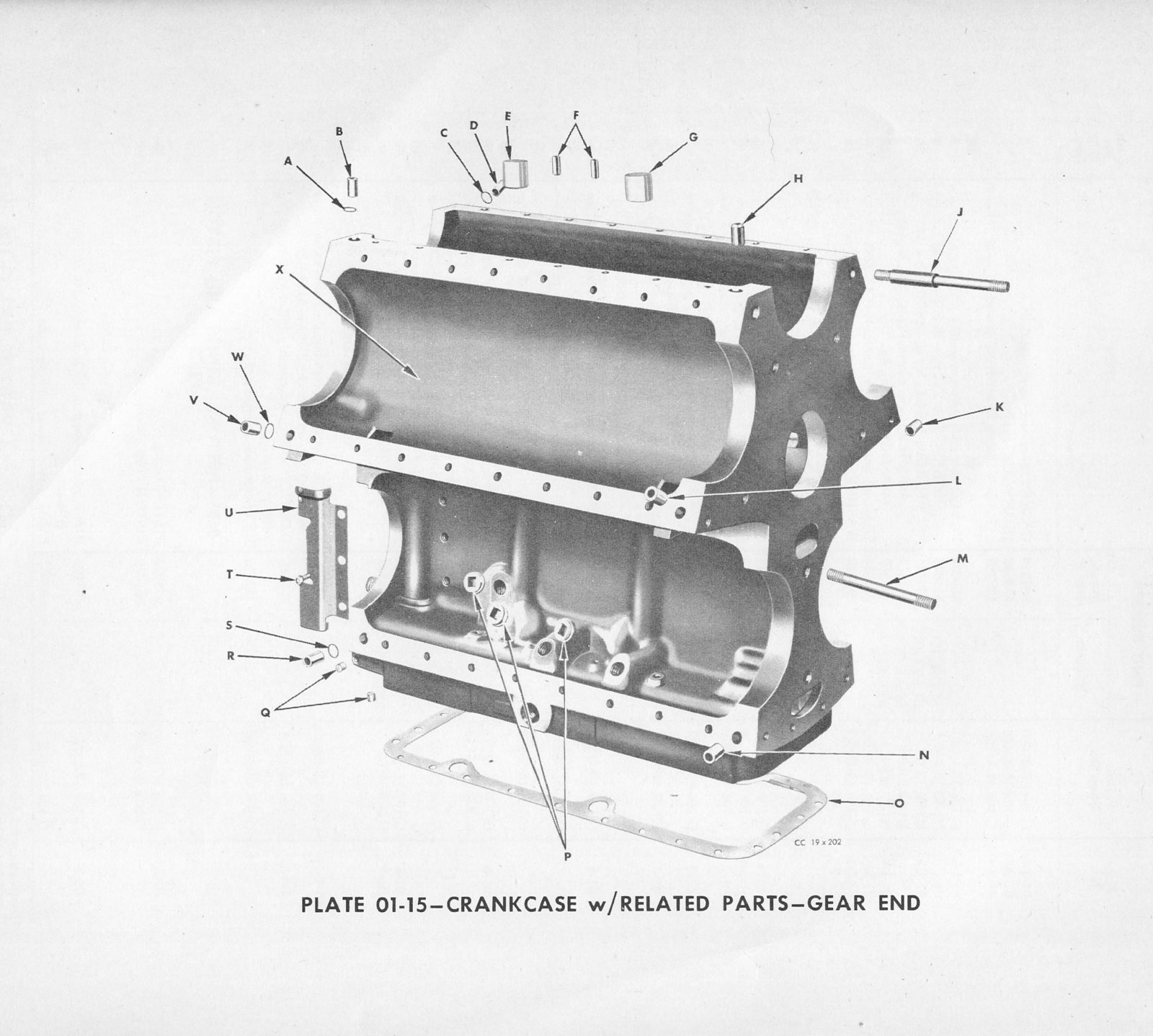

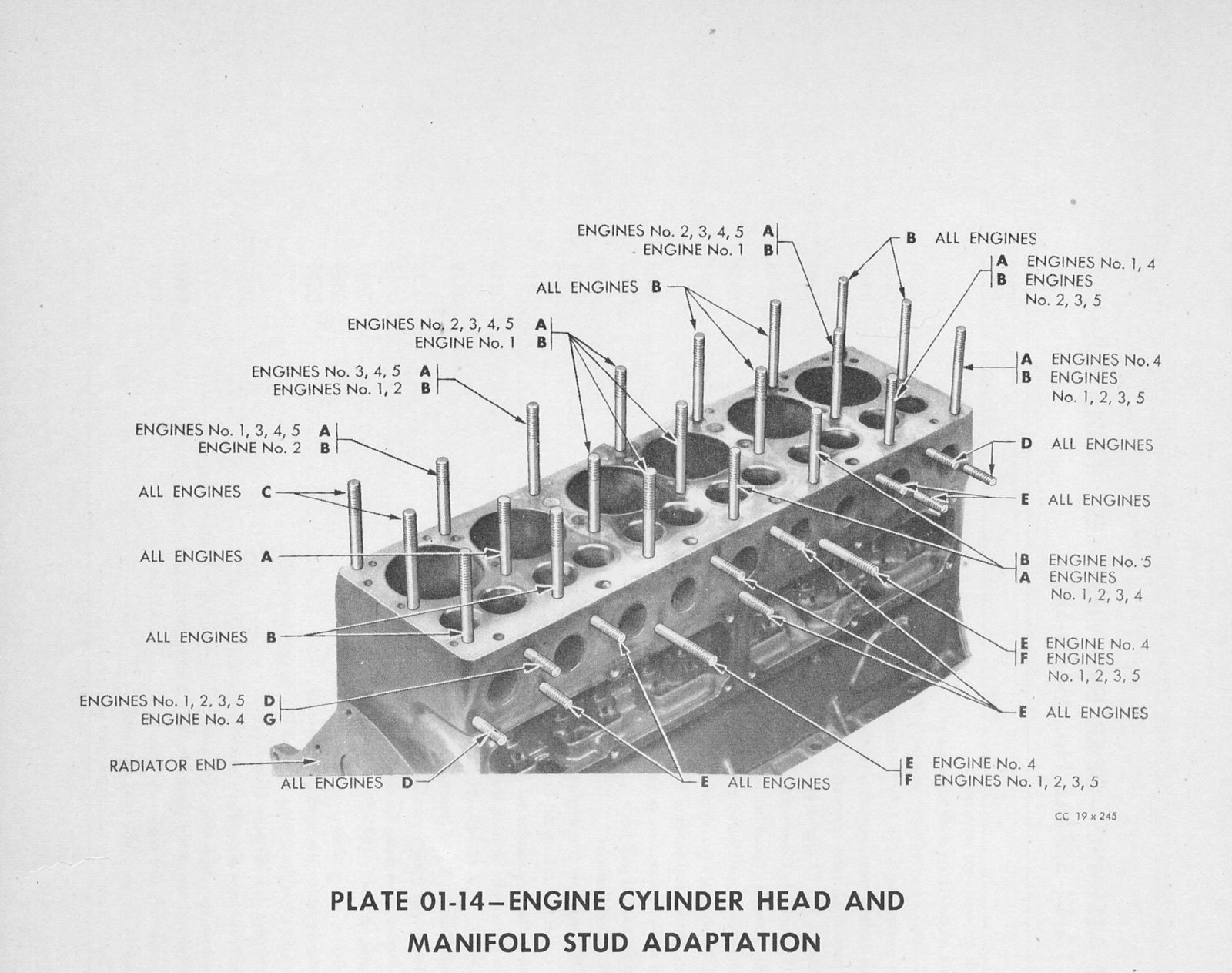

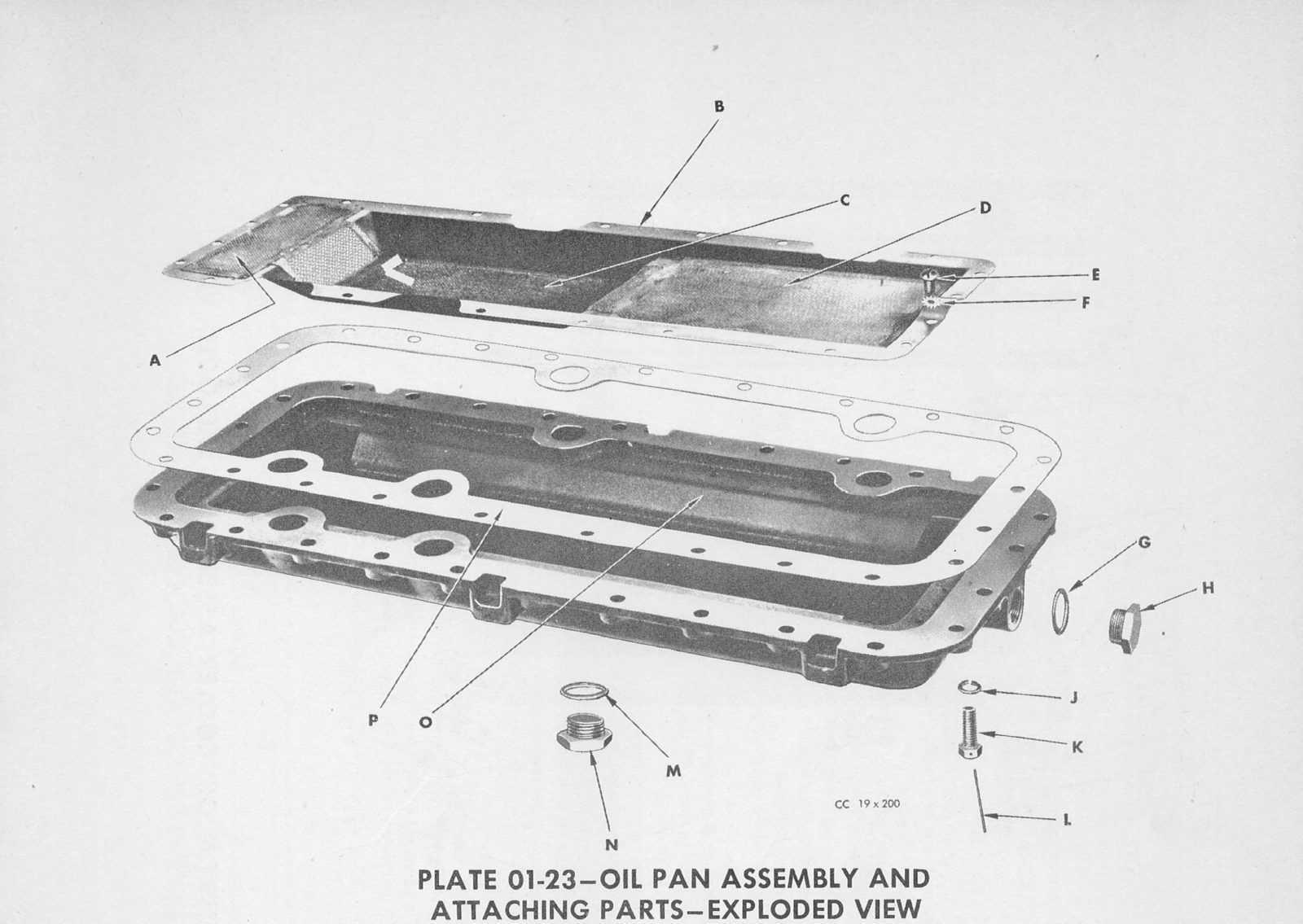

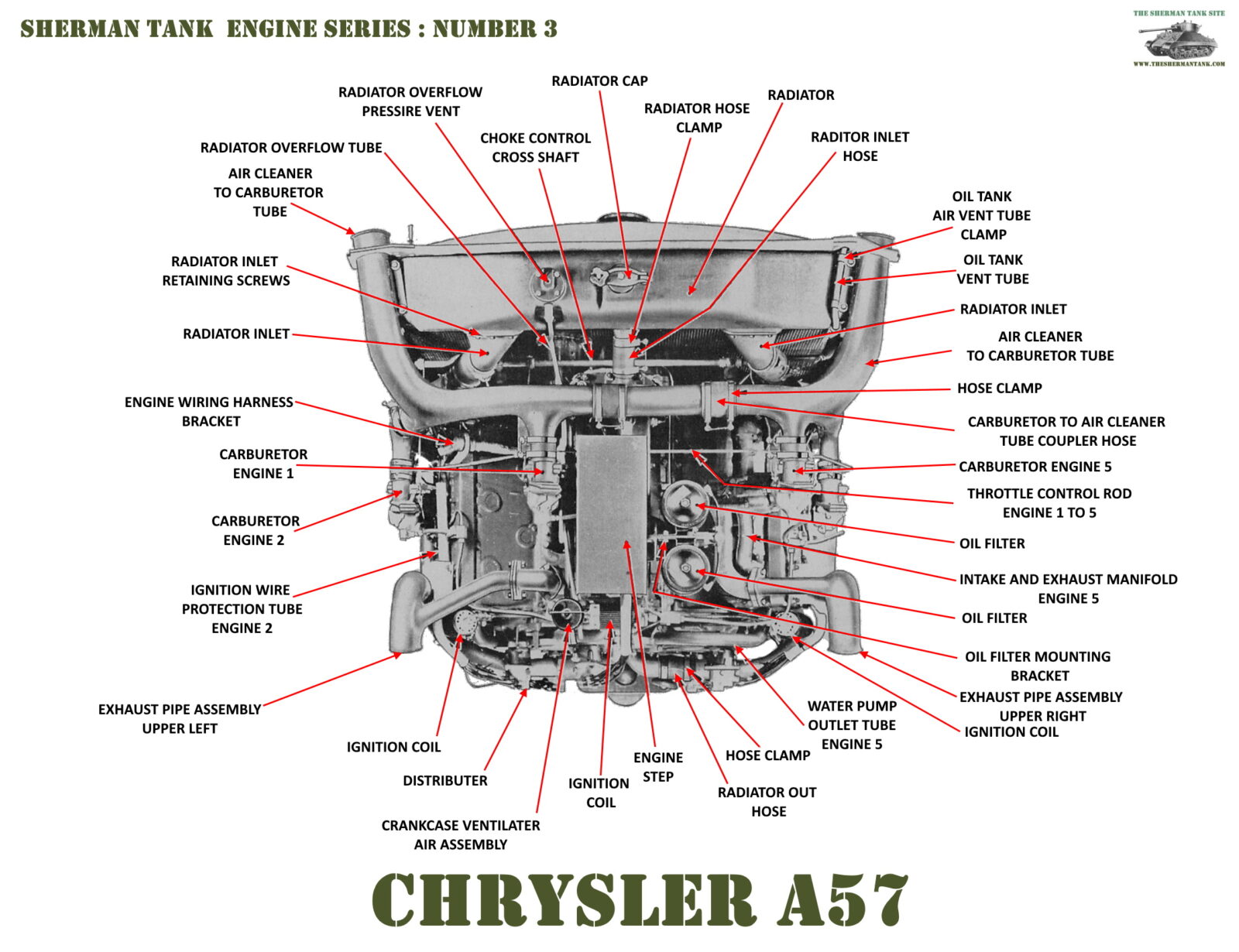

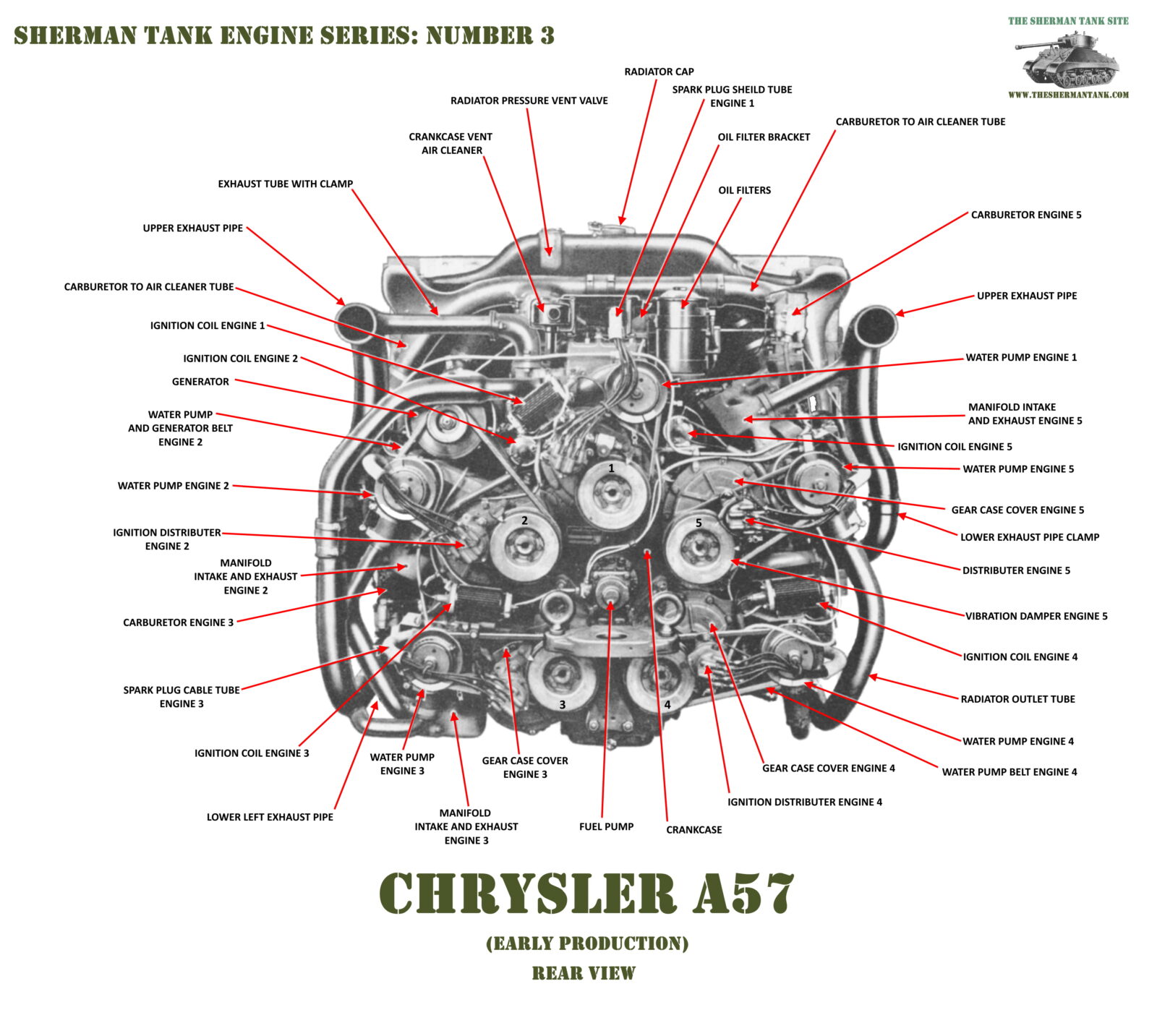

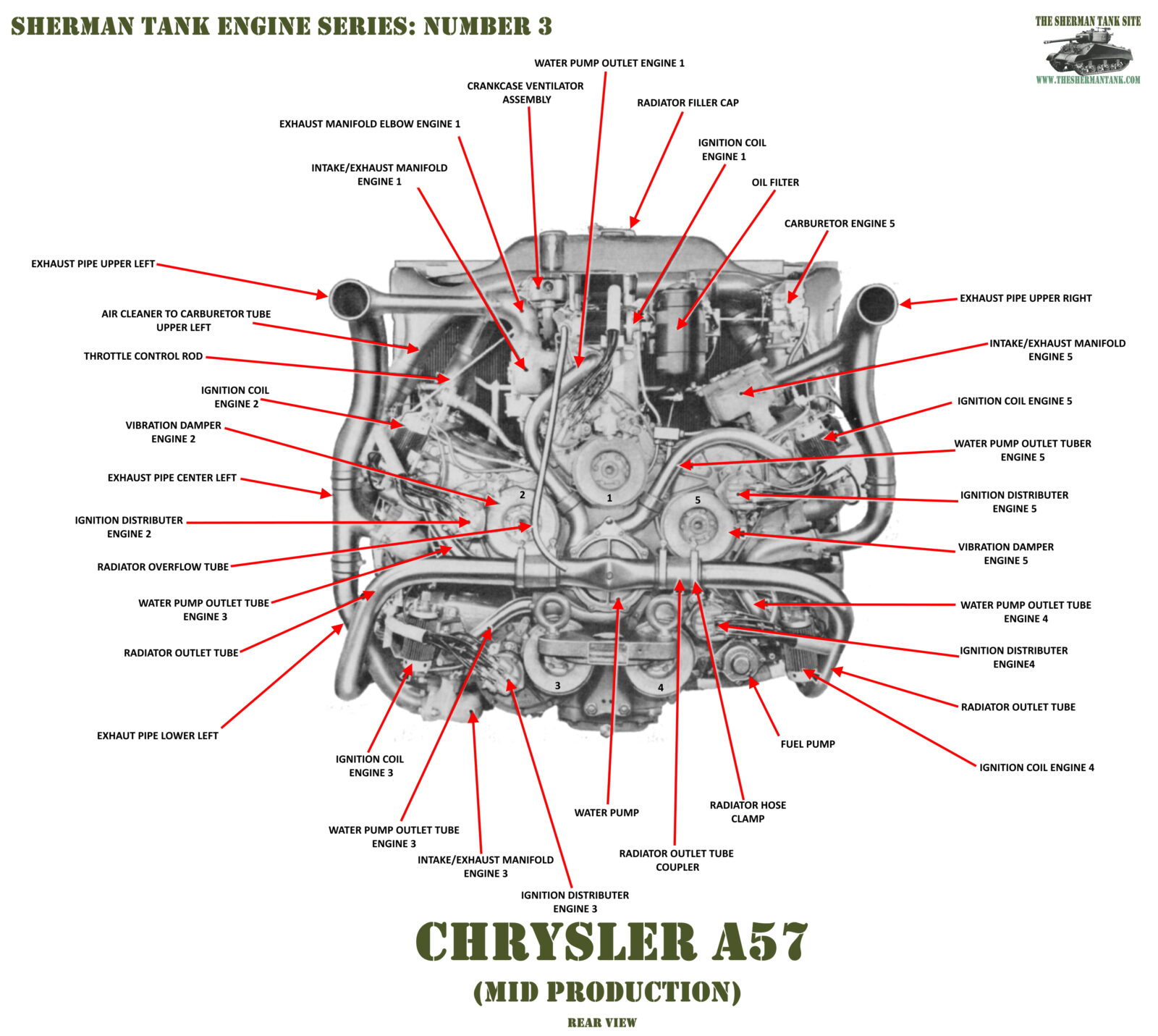

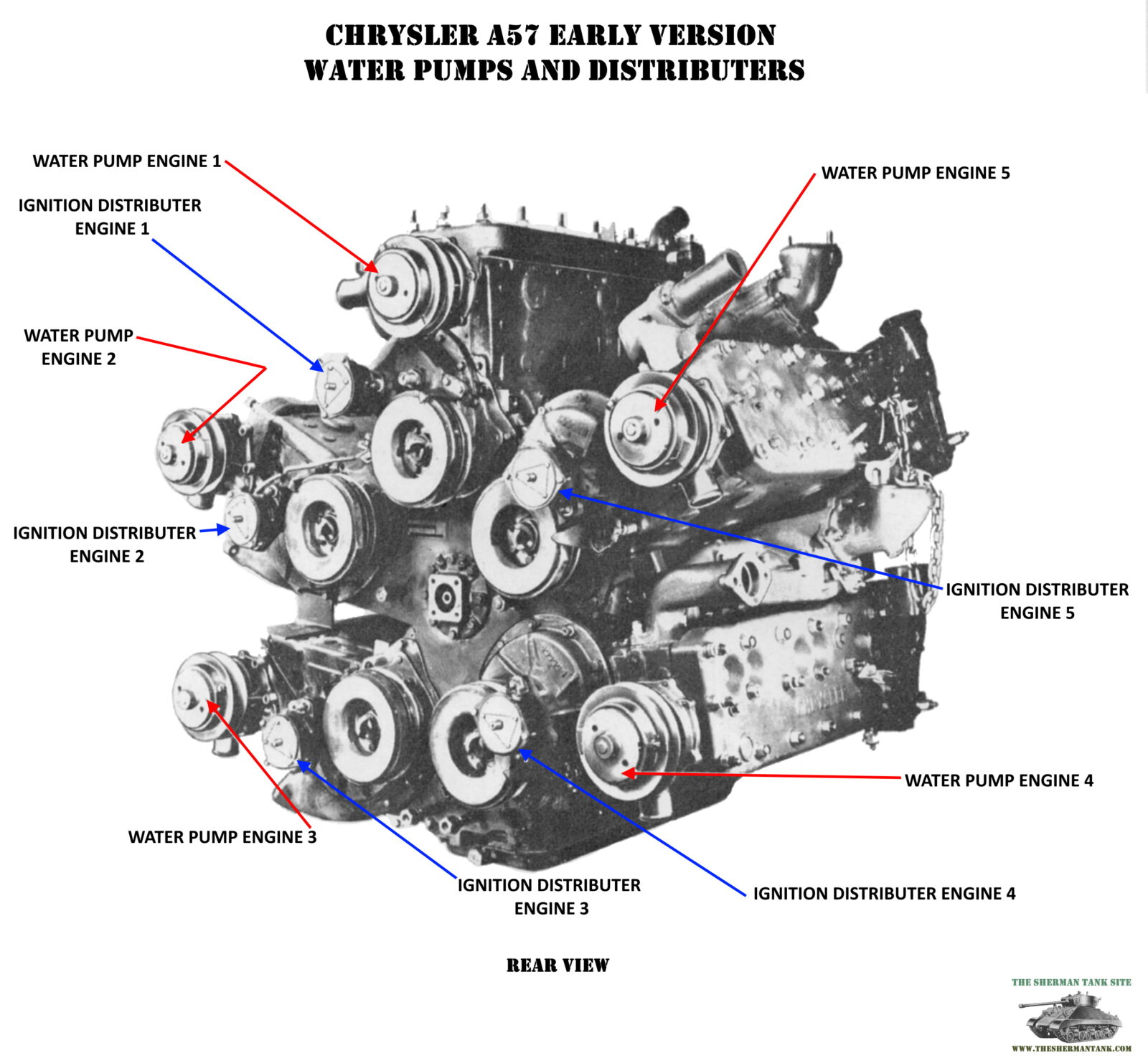

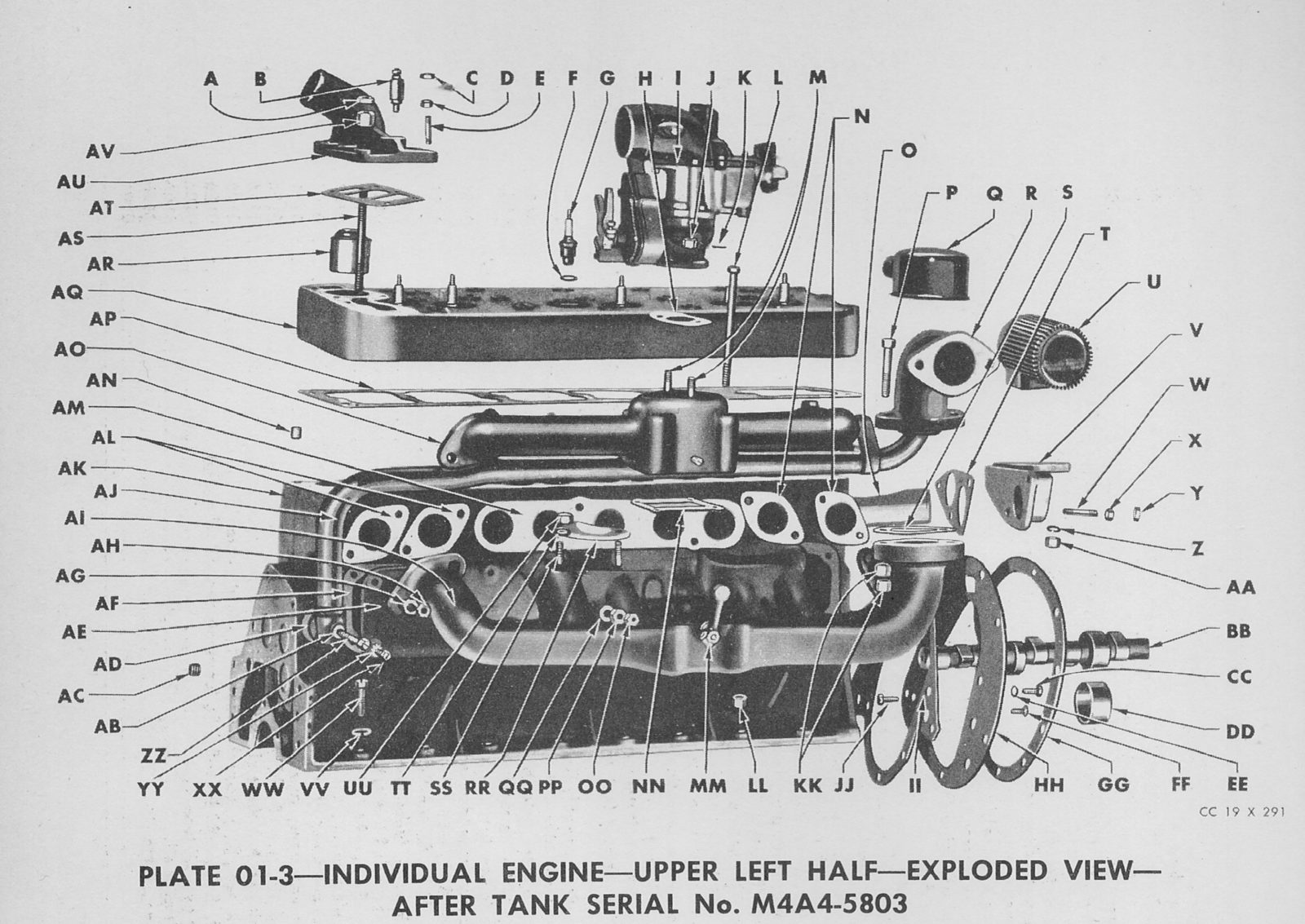

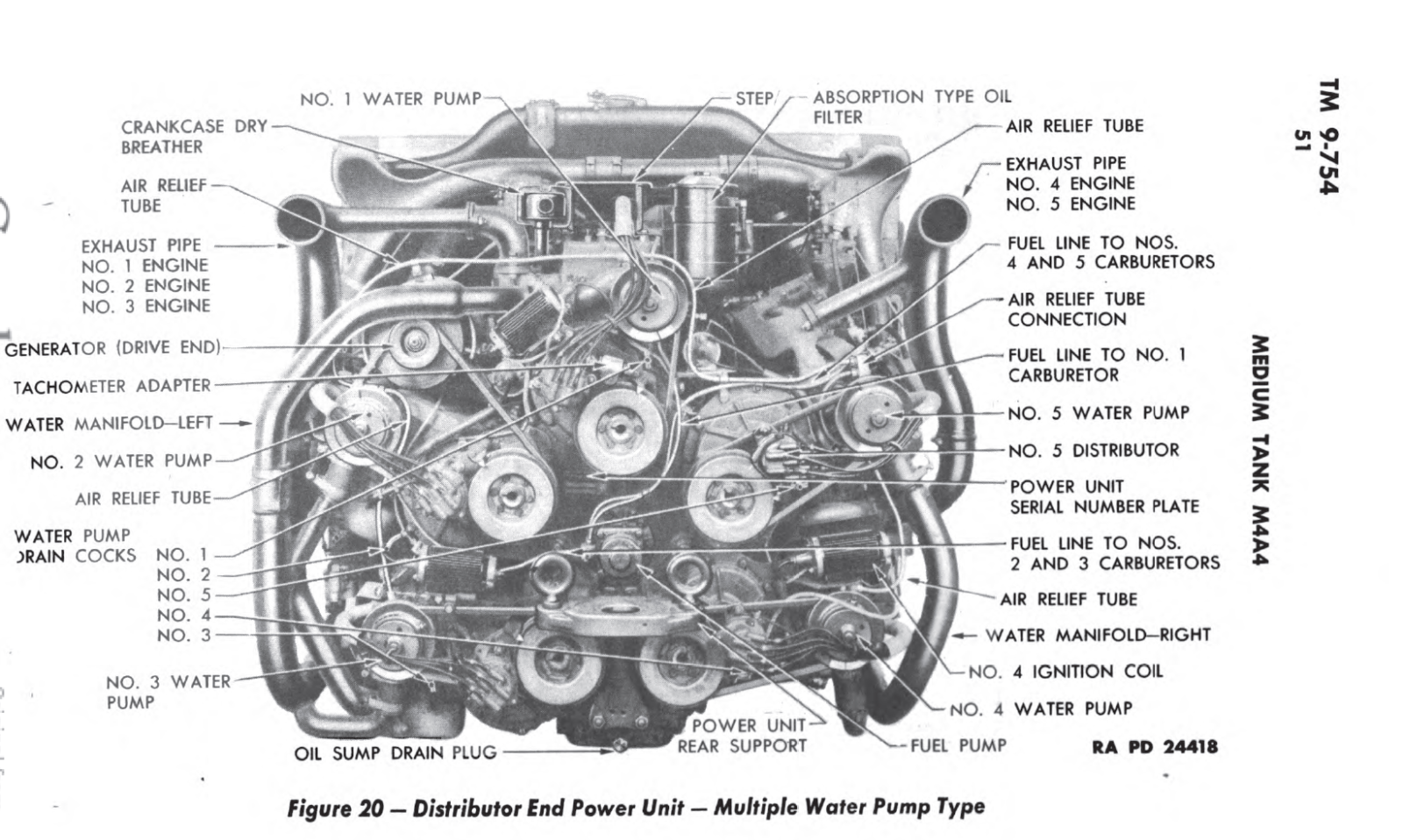

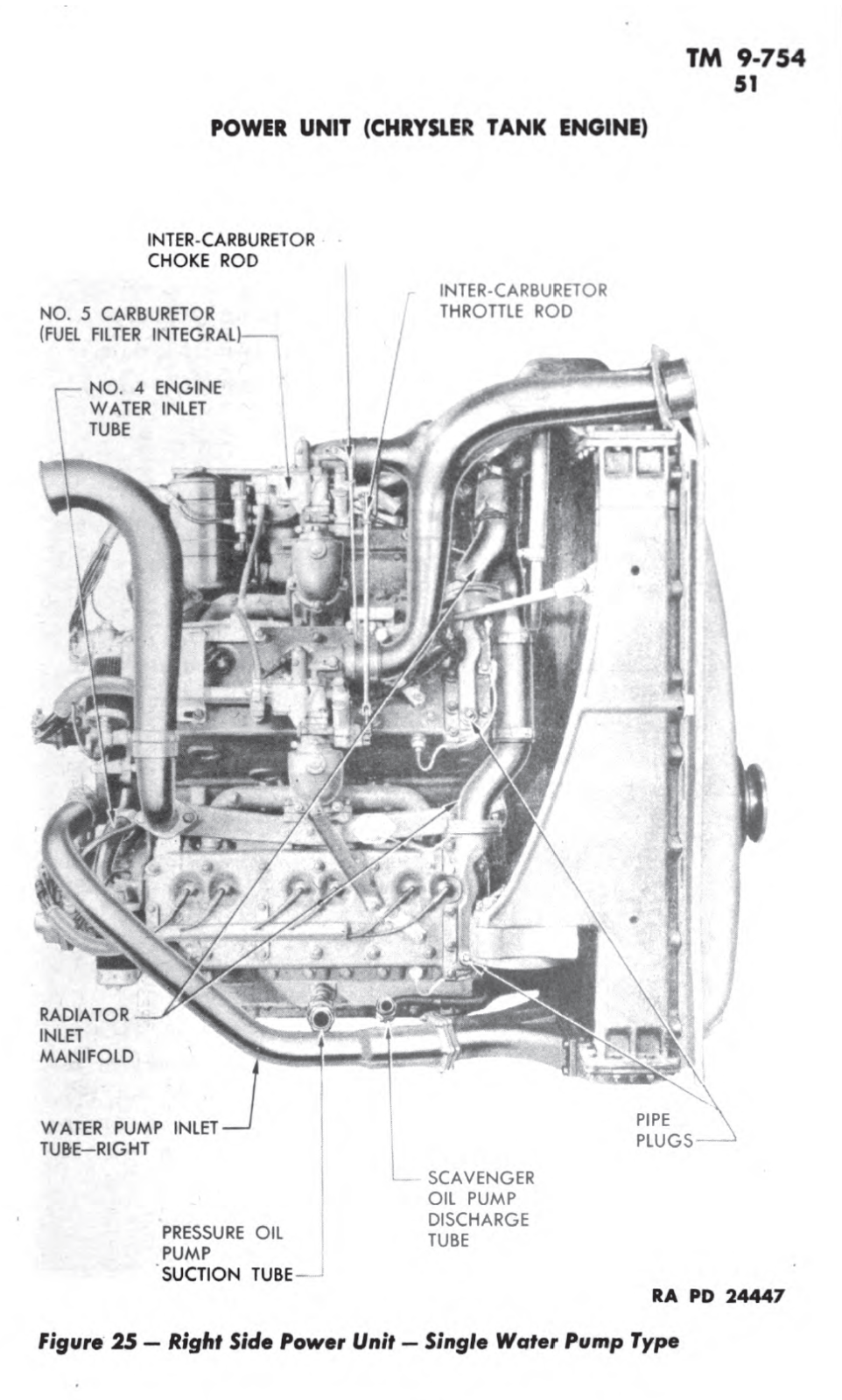

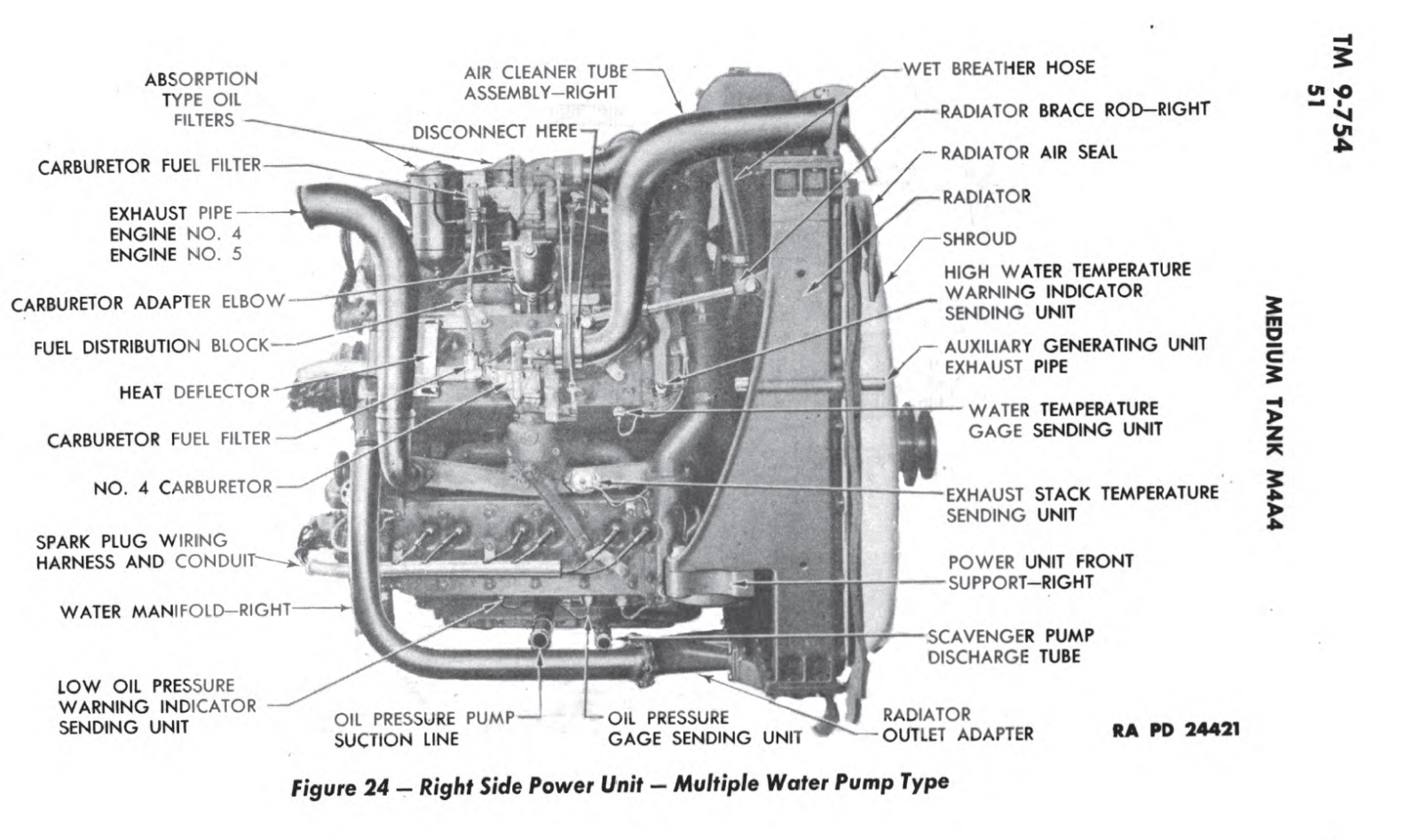

Chrysler decided the quickest way to get a motor into production was to take as must possible from their already solid automobile motor line. They chose the “Royal” inline-six making 115 horsepower. They decided to mount five them to one crankcase. They mated the power together with a complicated but very efficient gear train as at the front of each block. The new crankcase included the oil pan. The Oil pump system was changed, with two pumps being driven from a shaft taking power from the new gear train.

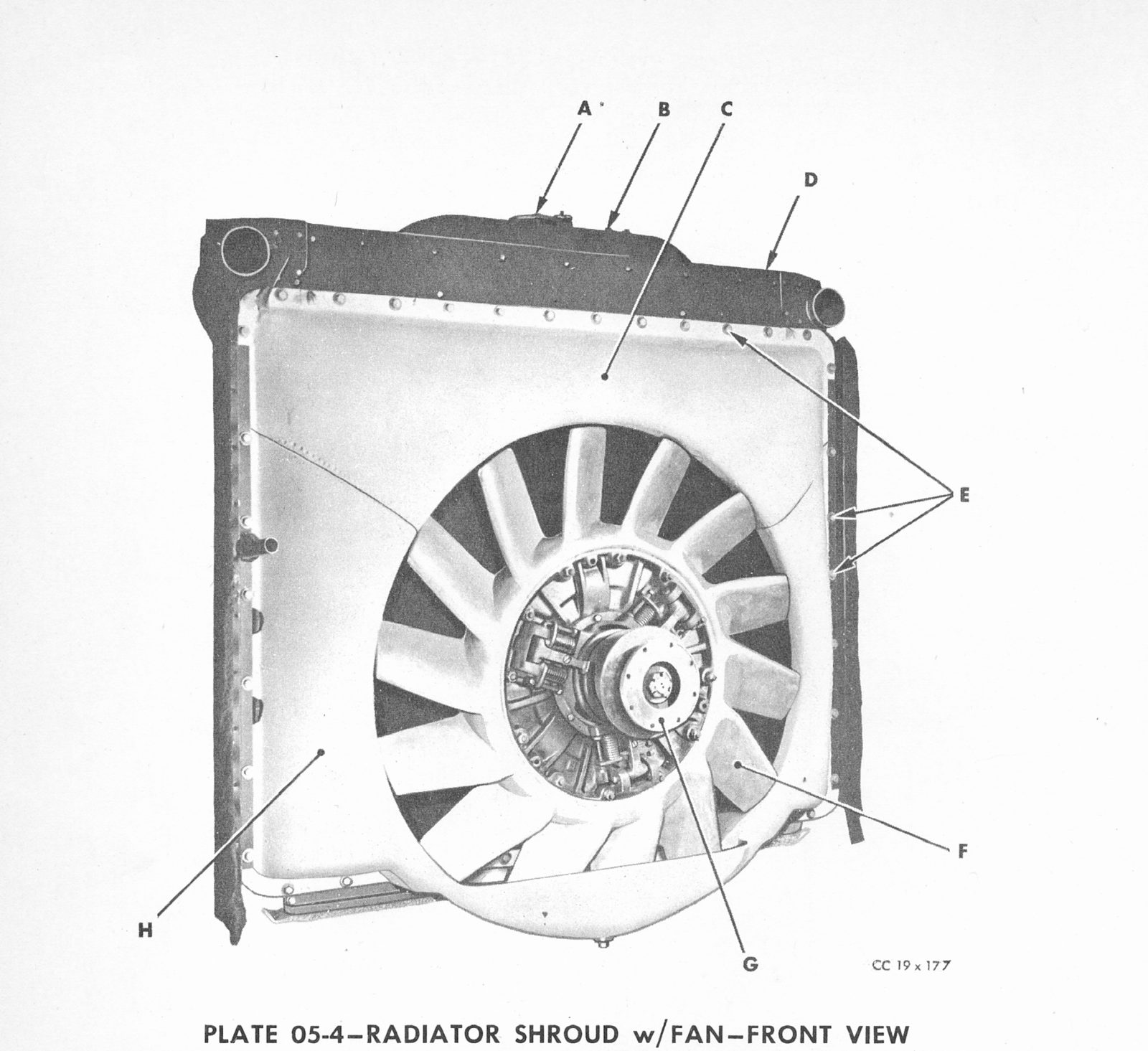

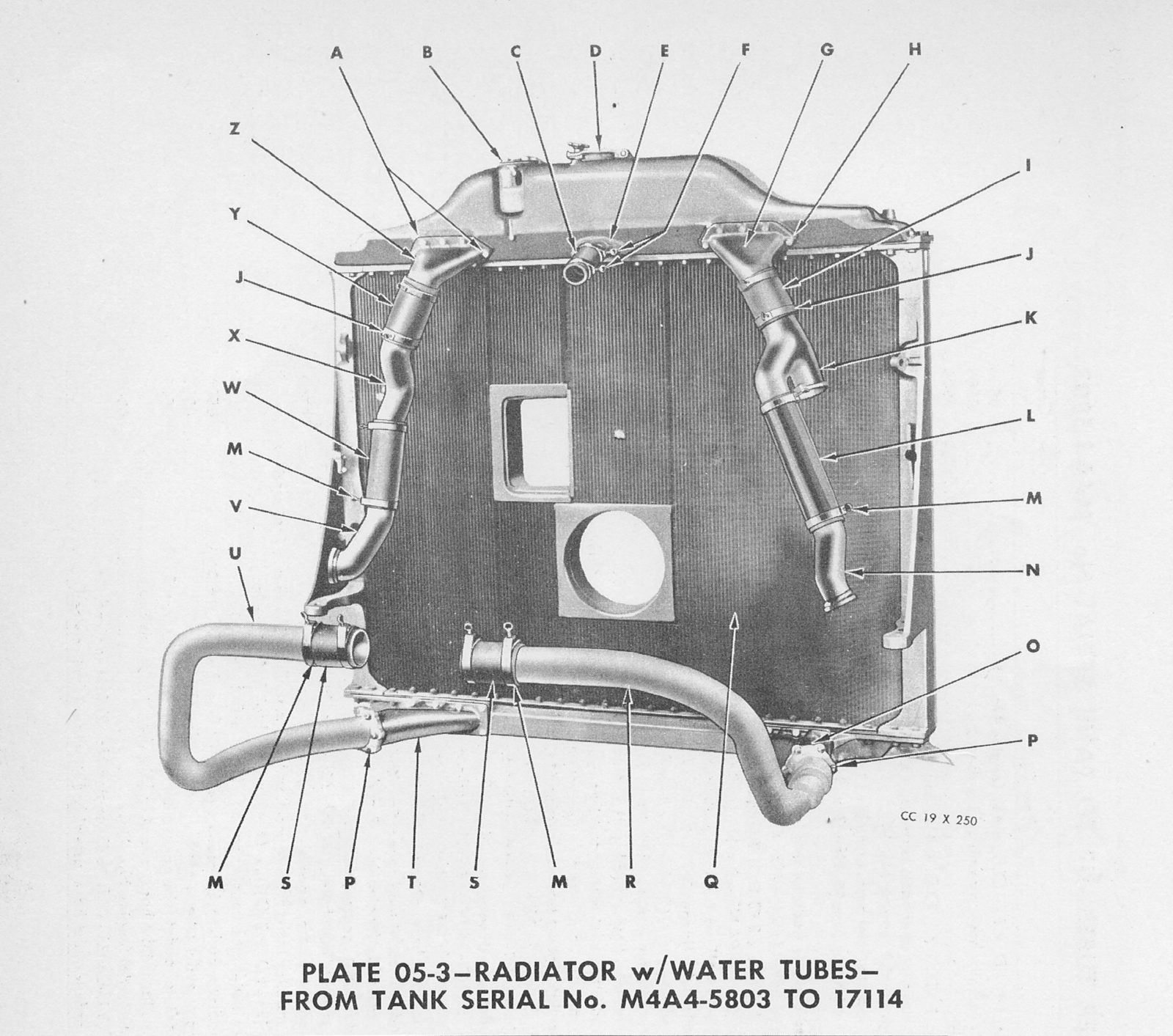

The test motors were ready for tank installations, and testing began by mid-November 1941, in the M3A4 and by February of 1942, the M4A4 was testing production motors. The US Army was satisfied with the power and driveability of the tanks using this motor, but the early motors had a lot of problems. The biggest one was overheating, caused by fouling by grease and dirt of the radiator. Other major problems included water pump and generator failures. The final complaint was it was difficult to work on in the cramped engine compartment. None of these problems were insurmountable, and Chrysler went to work on fixing them.

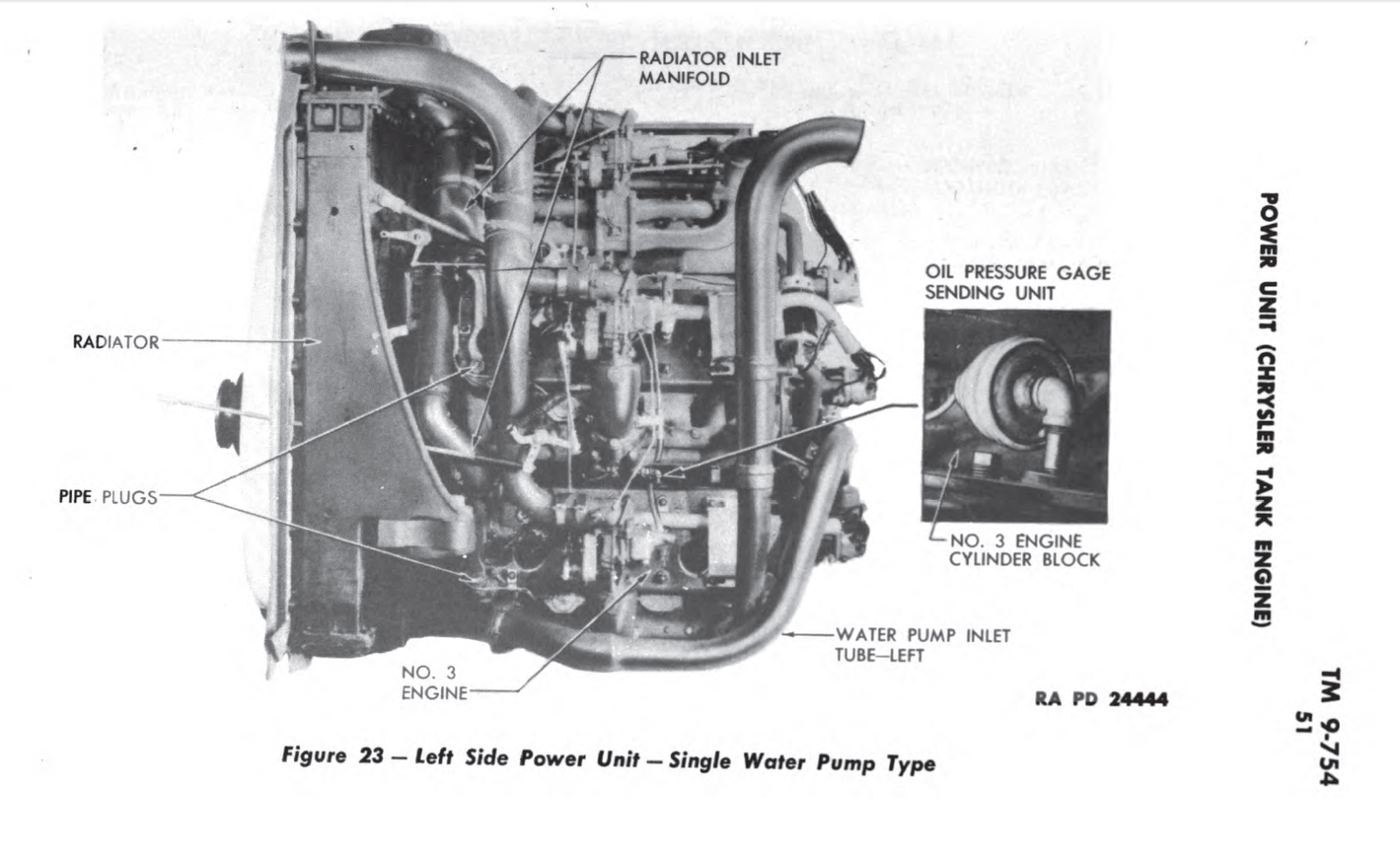

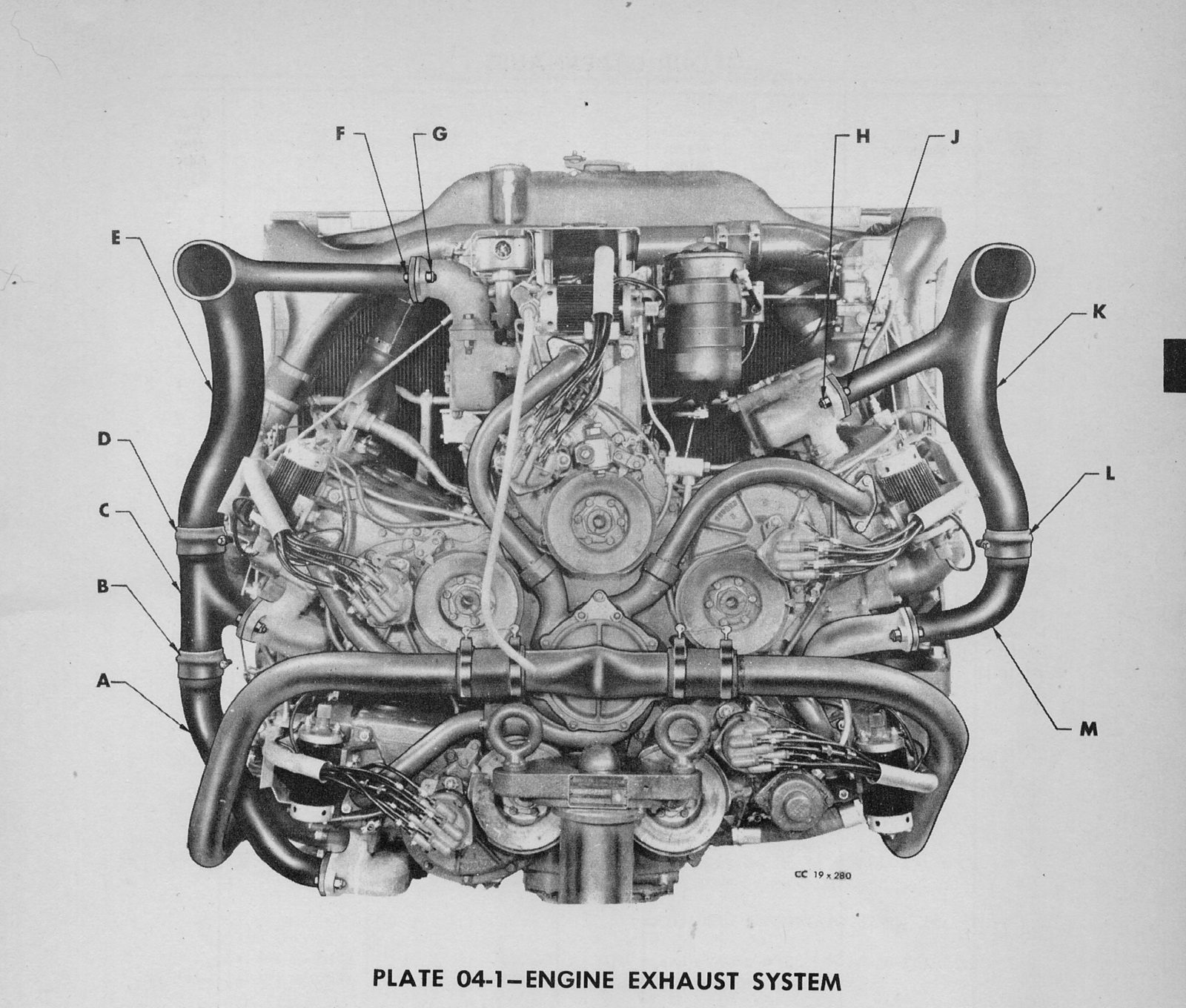

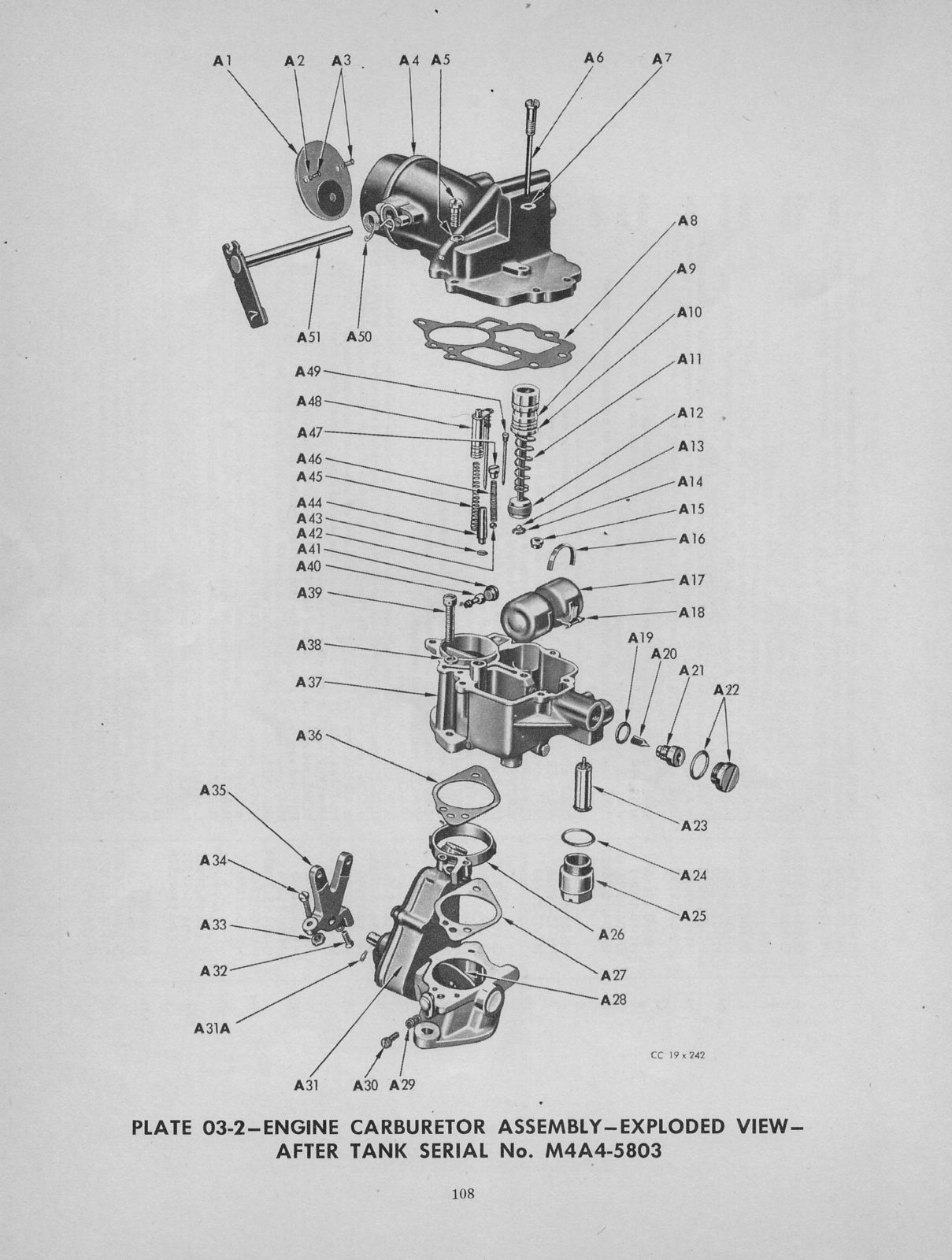

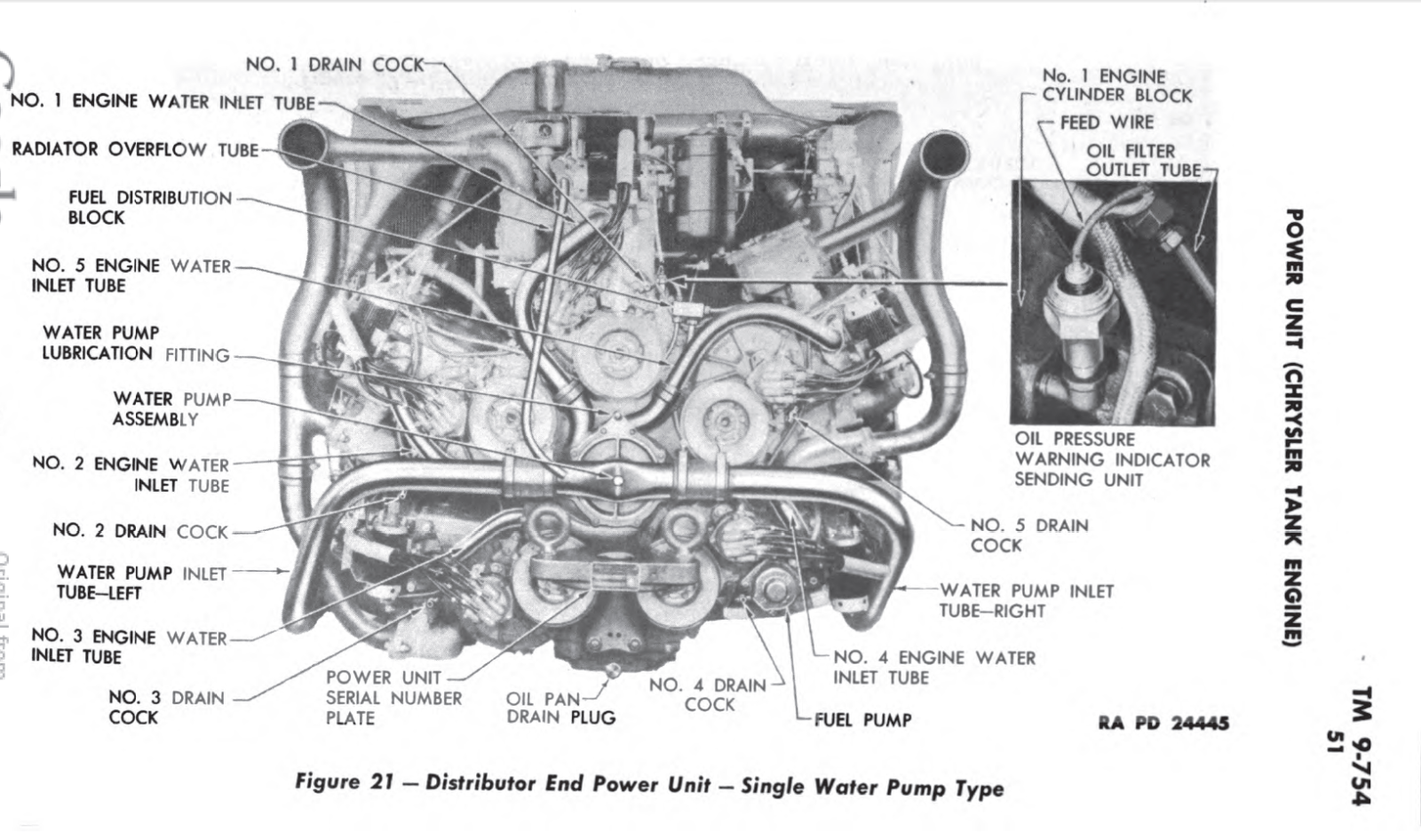

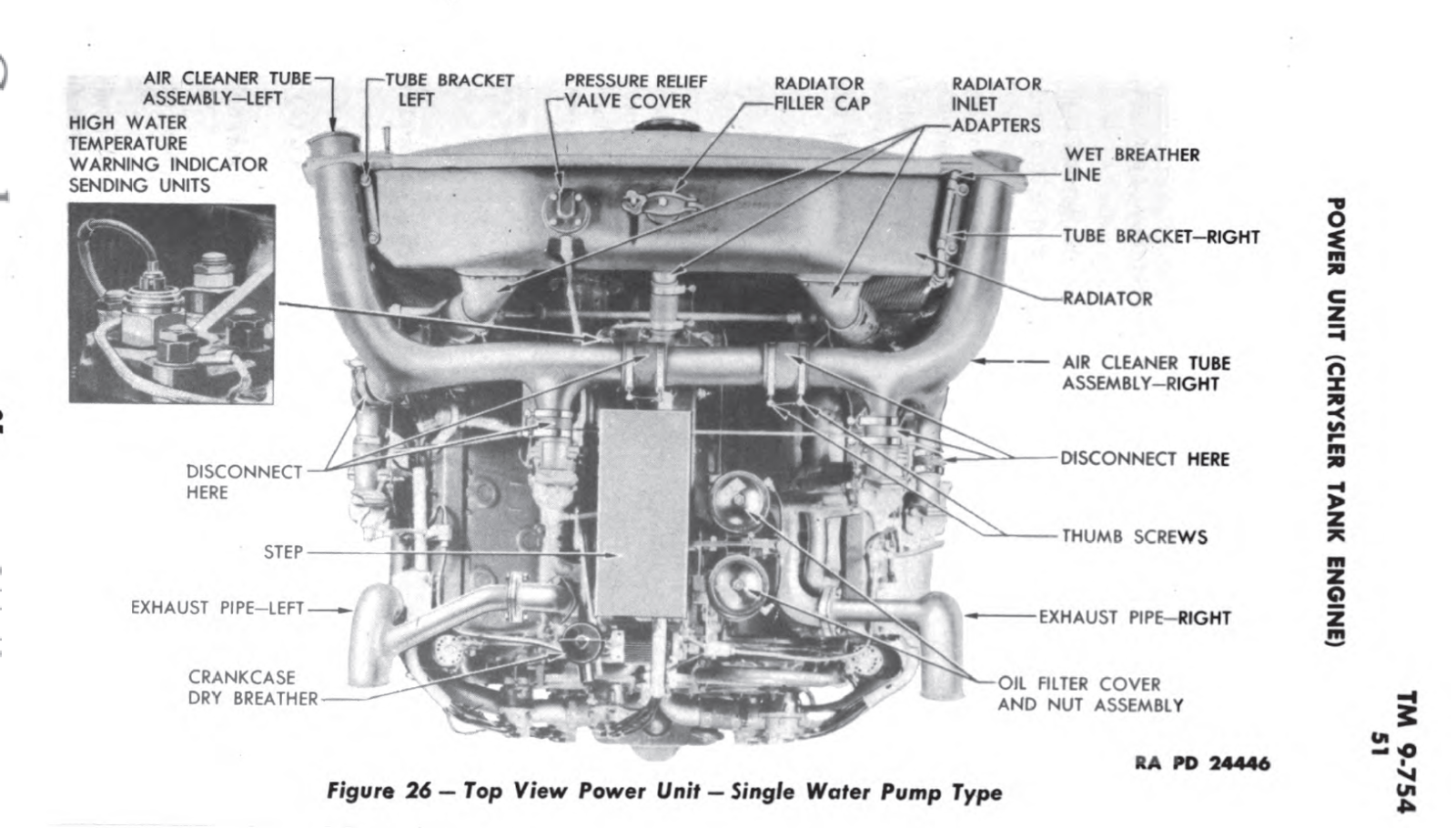

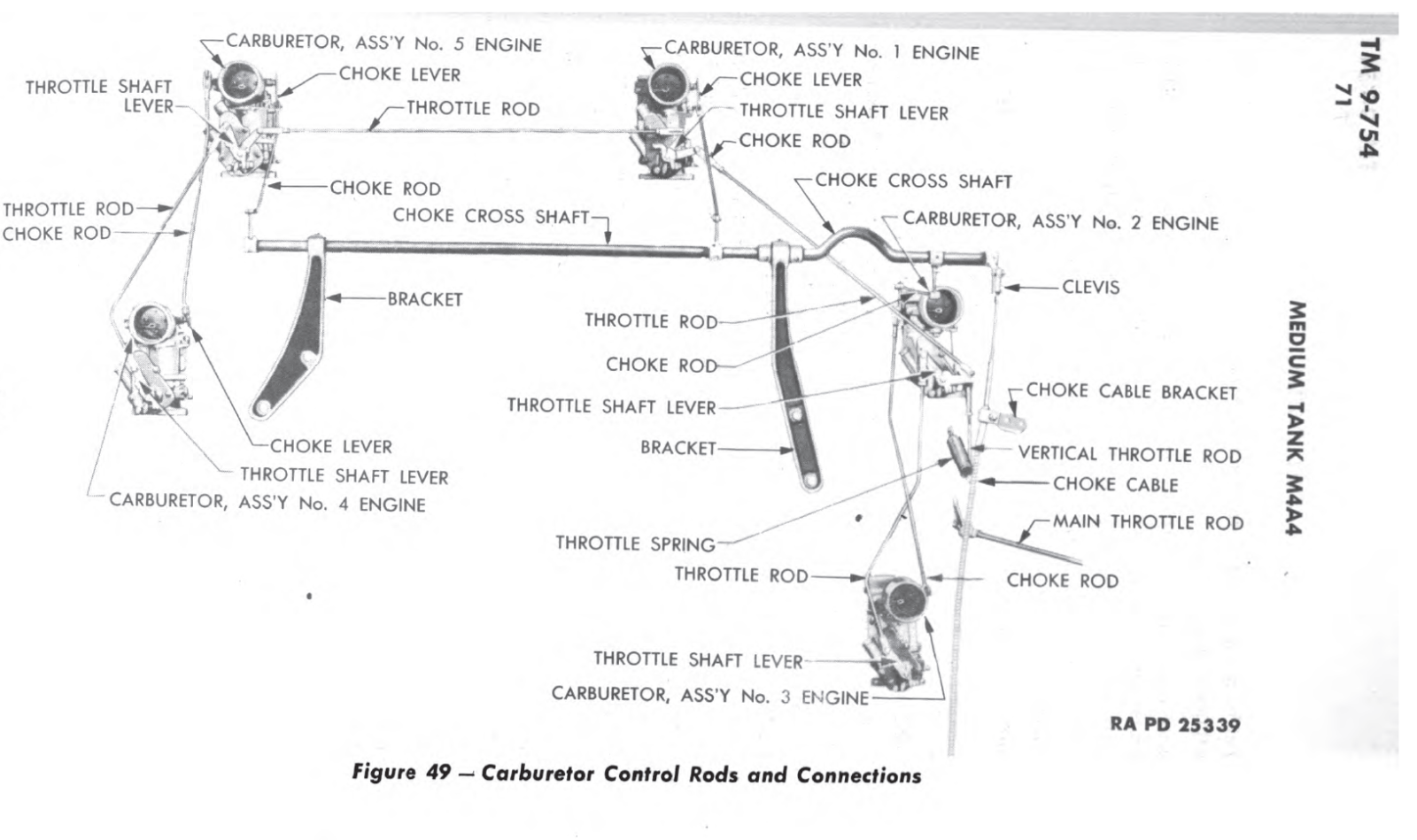

The cooling issues were found to be caused by a poorly sealed area around the radiator, and parts not being strong enough, and water pump failures. The individual pumps were dropped and replaced by a gear-driven single unit. The engine blocks were not designed to sit at an angle, needed their water jackets redrilled to improve flow as well. The reliability issues were solved by moving the generator from the motor to the fighting compartment, where it was driven off the drive shaft. They also moved all the carburetors from near its intake manifold, to the top of the engine, making them readily accessible. The flow problems of having longer, unequal length intake tubes was solved with baffles in the tubes. With these changes, it became as reliable or more so than all the other Sherman motors, but the GAA. The A-57 was averaging 240 hours before a serious failure, the GAA 255 hours and the R975 only 218!

The Army had made up its mind before Chrysler had fully improved the motor, they wanted nothing to do with it. Yet, the M4A4 was in production, and to make the tank production goals for 1942, it had to stay that way. So they were used for training in the United States. The British, who wanted M4 or M4A2 Tanks were competing for tanks with the Soviets and the French took them and made them work. The Soviets refused to take any after two test tanks were sent their way.

Chrysler and Ordinance Department of the Army knew the A-57 was a dead end, they decided to see just how good they could improve its reliability and a few more changes would give the A-57 top in class reliability. The Army noted that in almost all cases of failure in the A-57 was from piston ring and exhaust valve failures. They installed stellite-faced, sodium-cooled exhaust valves, and chrome-plated top piston rings and the A-57 was able to pass the 400-hour, 4000-mile endurance tests with only one failure in the four tanks tests. No other powerplant accomplished this, and the A-57 was deemed the most reliable of the engines in February of 1944!

This motor was an orphan in US Service. It powered the M3A4 and M4A4. The Army used the motor for training and tried to pawn a few off on the Marines. That lasted about two months at the Marine Tank School. The ever-growing need for tanks by the British ultimately solved what to do with the tanks that ended up with this motor. They would end up taking nearly 8000 of them. Chrysler sent tech reps to England with these tanks and showed the maintenance crews how to keep them running. This worked well and the engines served their purpose with little trouble. Often powering the best pure AT version of the Sherman, the Sherman VC Firefly. This motor saw a lot of use, during the war, and after with many countries being given Firefly Shermans to help out their recovering militaries. Some even ended up in South America, but I’m not sure what versions. This is my favorite Sherman motor because it’s so absurdly complicated, it’s almost German, but it actually worked, so not German at all.

This motor was fairly robust and would continue to run and allow the tank to move with three of the five-cylinder banks not working. This would make the tank severely underpowered but would be useful to get it back to the repair yard or onto a dragon wagon. I’m sure it was much more common to have one of the five not operating right, and that level of power loss would be an annoyance, but wouldn’t keep the tank from fighting if it was really needed.

During the war, Chrysler really went to bat to keep these motors working well. Since it was based off a motor already long in production, spare parts were readily available. I’m not sure how long support for the motor lasted after the war. I doubt it was very long, and American car parts were probably not easy to acquire to keep these motors running. Because of this, the M4A4, more than any other model seems to have its engine replaced in post-war service. I’ve read about the twin diesel and the R975 being swapped in. There are a few M4A4s around in Europe with running A57 motors, both fireflies if I recall right. You have to love anyone willing to keep one of these motors running.

Daily maintenance could be done with the motor in the tank, carburetor and timing adjustments, fluids and filters and things like that. If anything major needed to be fixed, one of the motors had a bad piston or valve, or even something minor like a big vacuum leak on the intake of one of the motors, or even a leak in the cooling system, the whole motor would have to be pulled. Chrysler knew this and made getting the motor in and out as easy as possible, including huge lifting eyes built on the common block to help lift the motor out. The British probably had several depots set up to rebuild A57 power packs that were in need of major work, and Chrysler made a lot of spare motors and parts to support the motor.