Suspensions and Tracks: It Suspends, and gets laid!

UPDATE! See the new Suspension and Track pages found here this post will no longer be updated, all the latest info I have will be put on these pages to make it easier to find.

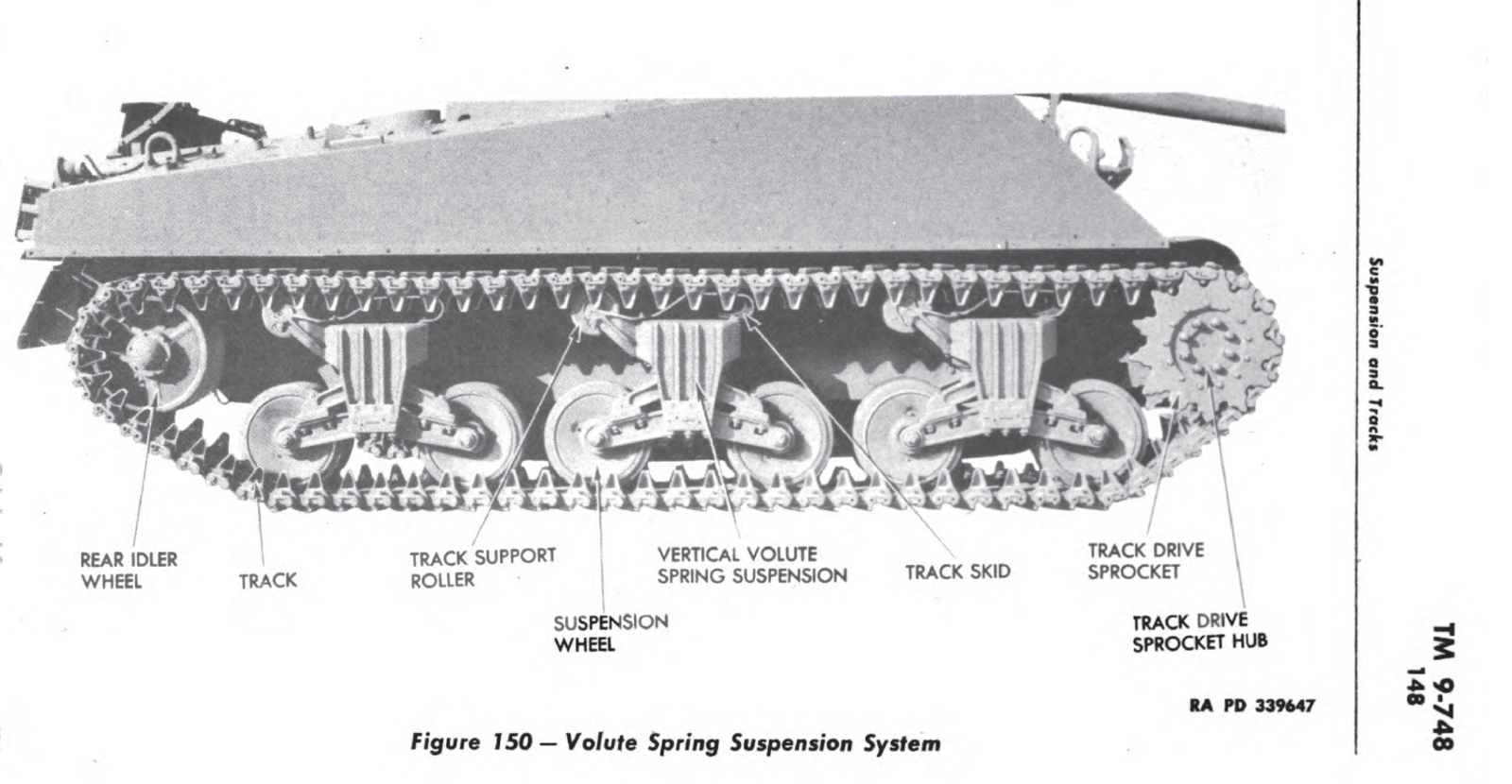

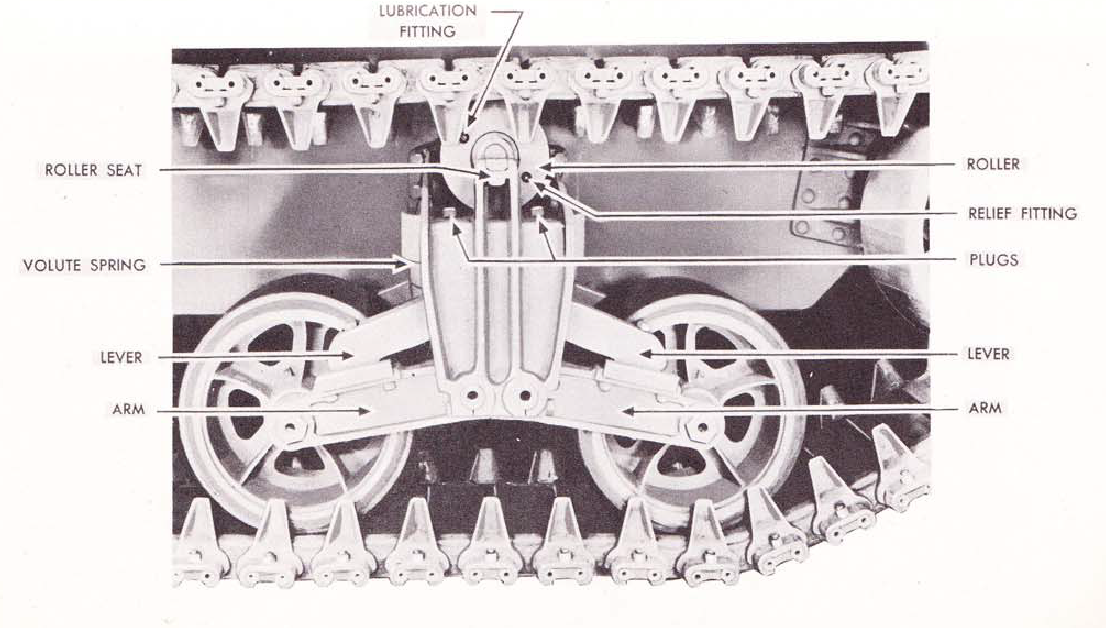

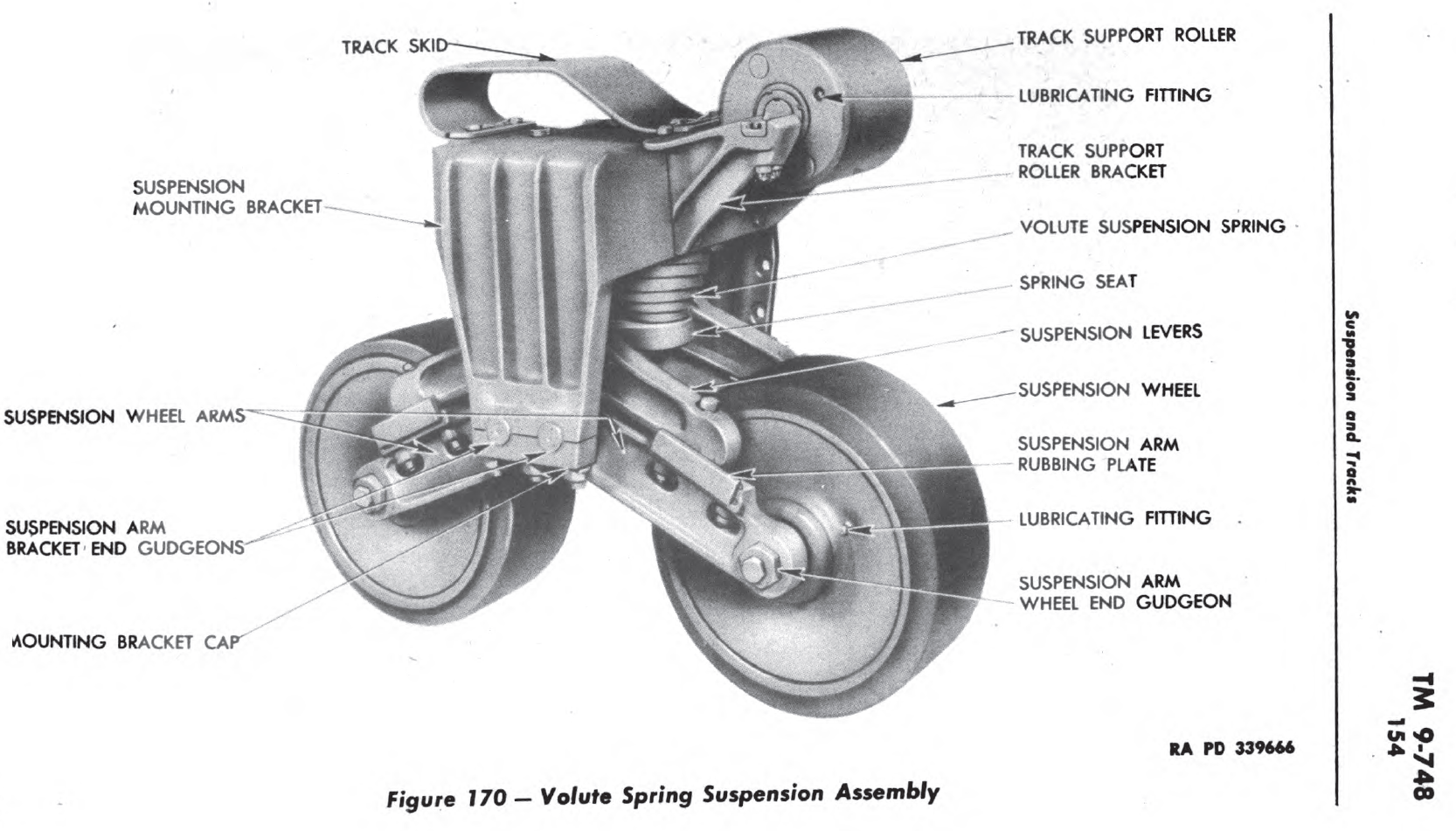

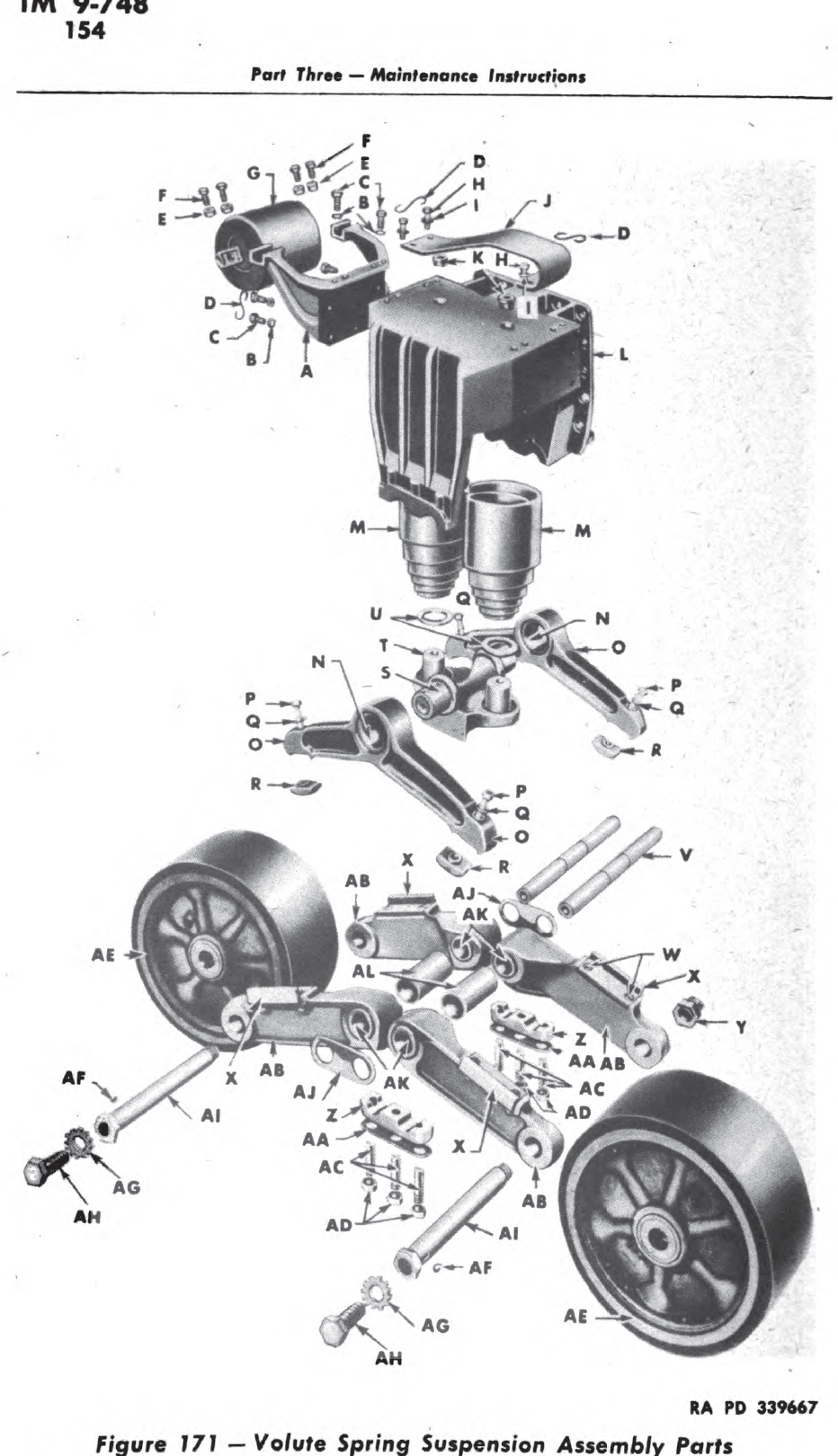

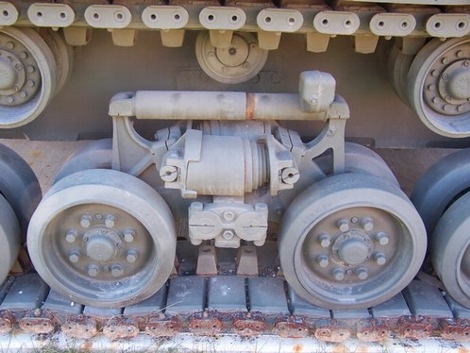

M4 tanks came with three types of suspension the early VVSS, VVSS, and HVSS. The early VVSS suspension system used 16 inch wide tracks. In the link above about Sherman details, you can see all the changes the basic VVSS system went through. The VVSS suspension went from the basic two road wheel one return roller with no support module as seen on the Lee, to the later production VVSS bogies that had bolt-on return rollers, that could be bolted to either side of the suspension unit, and sheet steel track supports and much beefier structures that were still usable on either side of the hull. The suspension was one of the parts of the tank that went through so many minor changes, keeping track of them is out of the scope of what this document is meant to do. The Sherman Minutia site does a great job of covering these changes. These changes had little effect on the performance of the tank; think of them as more of fine-tuning of the basic design for strength, longevity, and ease of manufacture.

What would be the final VVSS, with the return roller that could be swapped to either side, was developed for the M3A4, with the A57 multibank motor. The combo of heavier hull and engine was putting the basic VVSS suspension with the built in return roller under to much stress and causing premature failures. The heavy duty unit was developed to solve this problem was later standardized as the M4 suspension type, though, the bolt on roller and skids would still receive improvements, a beefier skid, and a spacer to lift the return roller, and later a new assembly that raised the return roller higher, the core remained the same. The M3A4 would be the only version of the Lee to receive the heavy duty VVSS suspension units from the factory.

Early VVSS: Using 16 Wide Tracks

Mid VVSS: Still Using 16 inch Wide Tracks

HVSS: The Improved 23 inch wide Track and Suspension System

The VVSS was later replaced by the HVSS system that had twenty three inch wide tracks, but the suspension was still a bolt on module. It was very well received and used on many late production Sherman models and a few of the variants. It solved the floatation problem of the narrow tracks with few drawbacks. Thousands of 75mm Shermans received this suspension coupled to large hatch wet hulls. This would become the preferred suspension type for US Army Shermans, and many 75mm hulls either lost the suspension or had its 75mm turret removed and replaced with a T23 turret and 76mm M1A2 gun after the war

This type of system, that could be unbolted, was much easier to work on or fix when damaged than an internal torsion bar suspension or Christie suspensions found on other tanks. Changing the one bogey setup, or even two and putting the track back together was a lot easier than trying to get the stub of a broken torsion bar out of the hull so a new one could go in.

An experimental Sherman with torsion bar suspension was produced and found to be little better than the basic VVSS tanks, and no better than the HVSS tanks and production was never considered. The HVSS suspension made it onto a lot of things built on the Sherman chassis. HVSS was also retrofitted onto hulls used in Israel’s M51 Super Sherman program.

Tracks: They are a weapon too you know

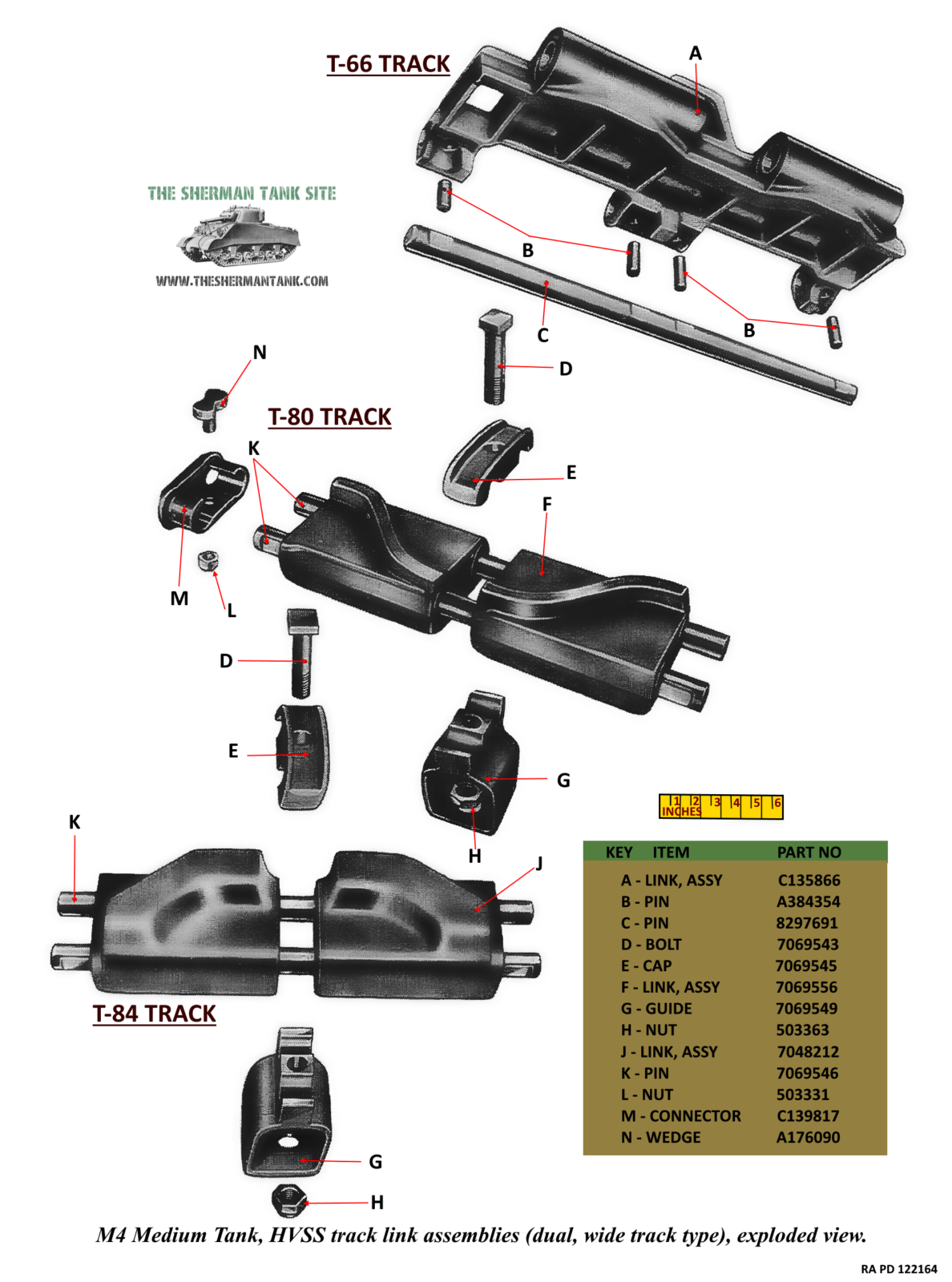

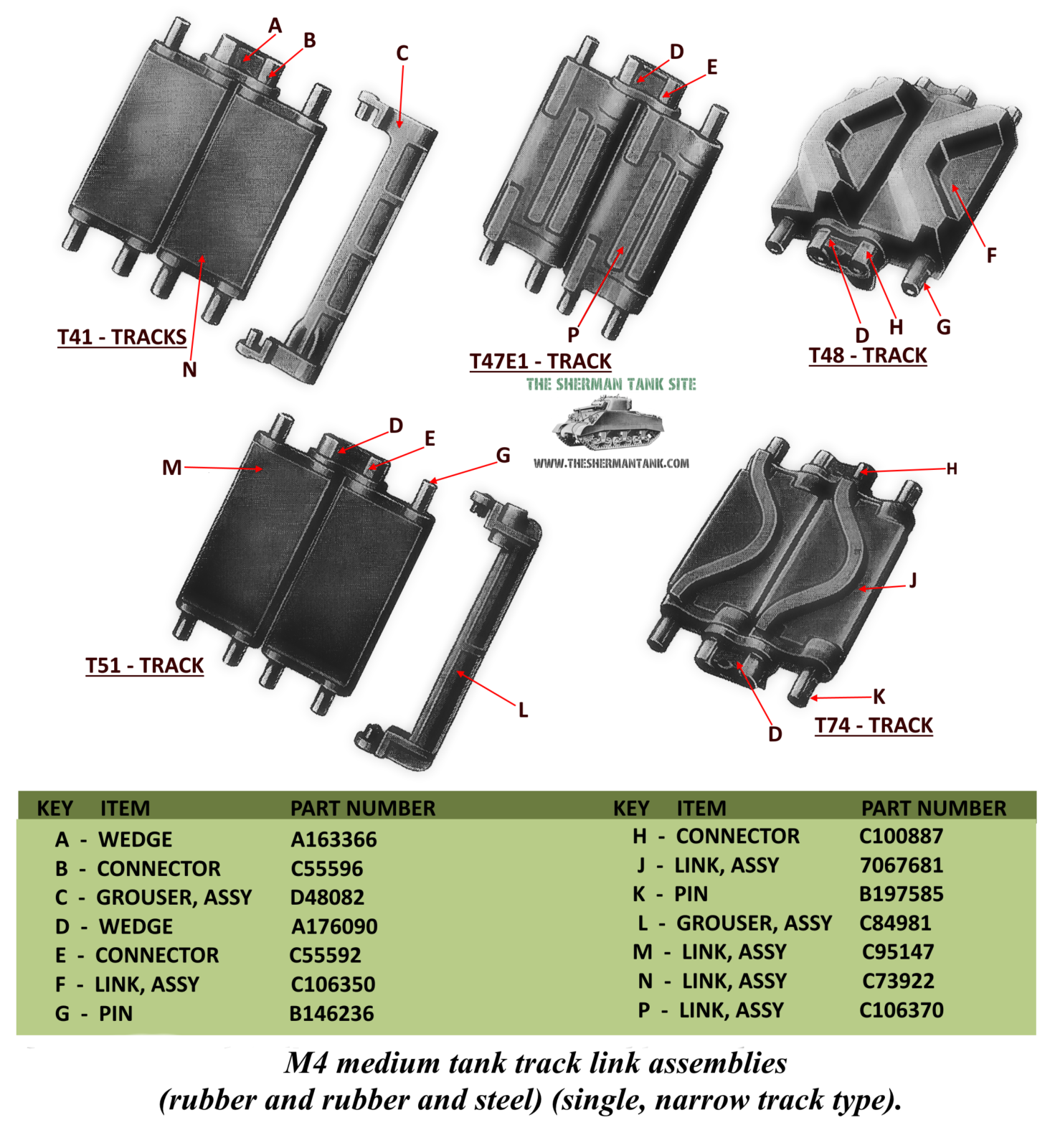

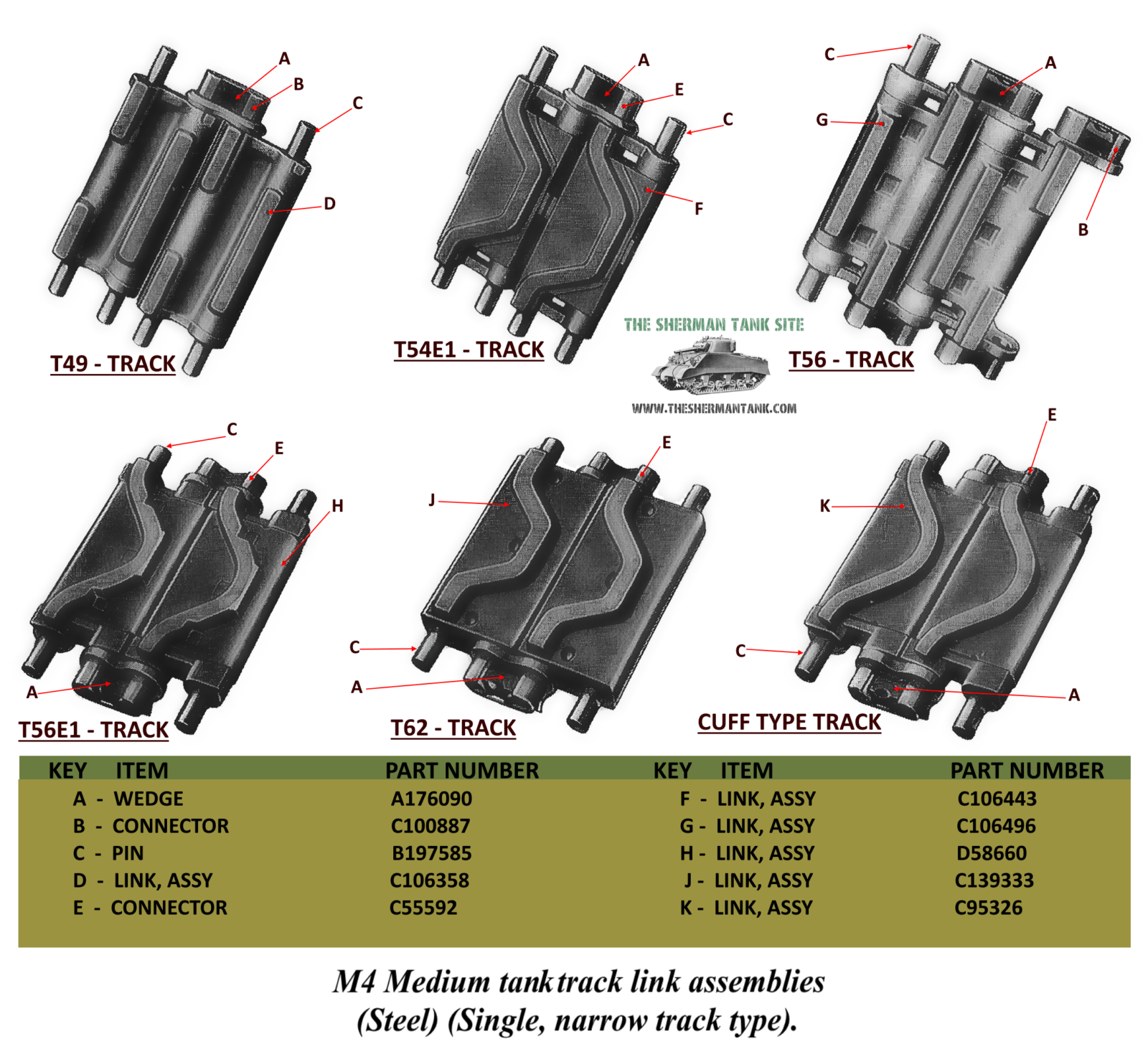

The Sherman VVSS had at least 14 different types of track, and there was another 4 typesfor the HVSS. I will cover them in more detail later. Most of the track types were ways to minimize the amount of rubber used in the tracks or to produce an all steel track, as good as the basic rubber and steel T41 track.

The Sherman VVSS had at least 14 different types of track, and there was another 4 typesfor the HVSS. I will cover them in more detail later. Most of the track types were ways to minimize the amount of rubber used in the tracks or to produce an all steel track, as good as the basic rubber and steel T41 track.

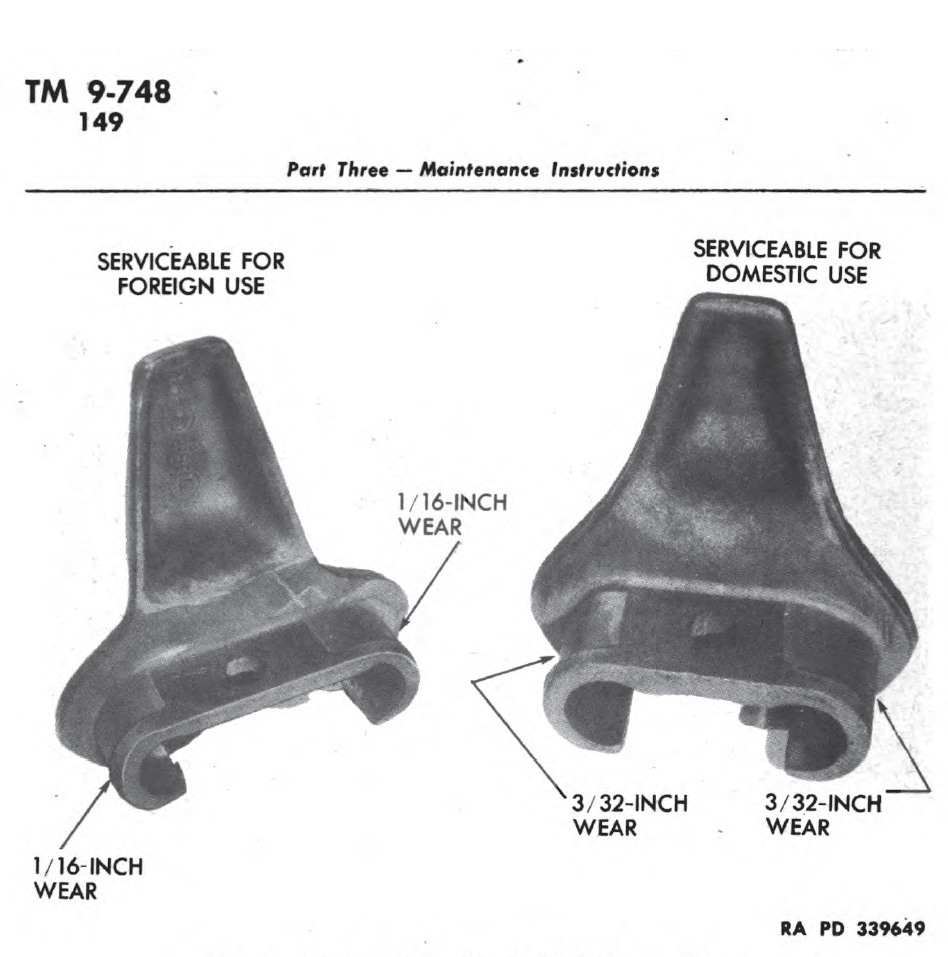

The narrow VVSS tracks limited the Shermans mobility in soft mud, sand, boggy terrain. The Tiger and Panther tanks were better off road than the VVSS Shermans. It’s a good thing they were so rare, and there was a limit to how much mud they could deal with. The mud also accelerated the maintenance problems both these tanks faced and eventually mud got so deep in late 44 no take could go off road much until the ground froze.

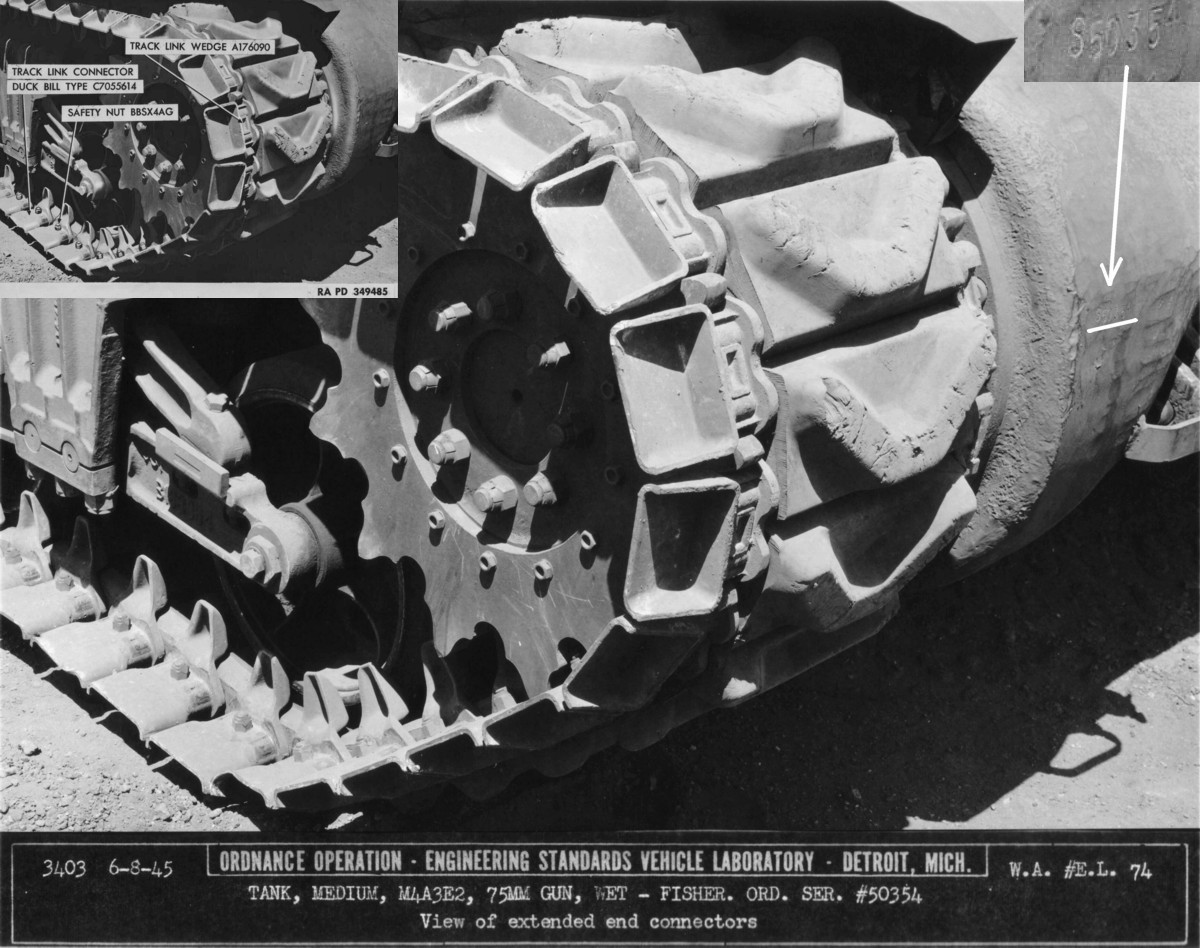

The Army came up with a field expedient solution called a “duck bill” end connector. The was an end connector with a sheet steel foot welded to it, when bolted in place on the track it added several inches to the tracks width in soft terrain. The only drawback was they broke off fairly easy, but were easy enough to replace. This was a very popular and widespread modification, and many little local factories in France were contracted to produce them. They were also factory produced and installed on production Shermans.

The Army came up with a field expedient solution called a “duck bill” end connector. The was an end connector with a sheet steel foot welded to it, when bolted in place on the track it added several inches to the tracks width in soft terrain. The only drawback was they broke off fairly easy, but were easy enough to replace. This was a very popular and widespread modification, and many little local factories in France were contracted to produce them. They were also factory produced and installed on production Shermans.

Sources: TM9-1750K Tracks-Suspension-Turret and Hull Mods M4 series,TM9-731B M4A2, TM9-731G M10A1, TM9-745 GMC M36B2, TM9-748 GMC M36B1, TM9-750M3, TM9-752 M4A3, TM9-754 M4A4, Sherman by Hunnicutt, The Sherman Minutia Site, Son of a Sherman by Stansell and Laughlin

Hello…¡¡¡ I wish to know if some E8,had totally steel tracks,without rubber…??

Very truly yours…¡¡¡ Enrique…¡¡¡

After reading your post, you have a great website with interesting content. But I think you can improve your current google ranks by using SEO website traffic net. My friend uses it and it works great. Just google it, it’s very nice tool to bring you a lot of new readers on a daily basis. Keep up the quality work!

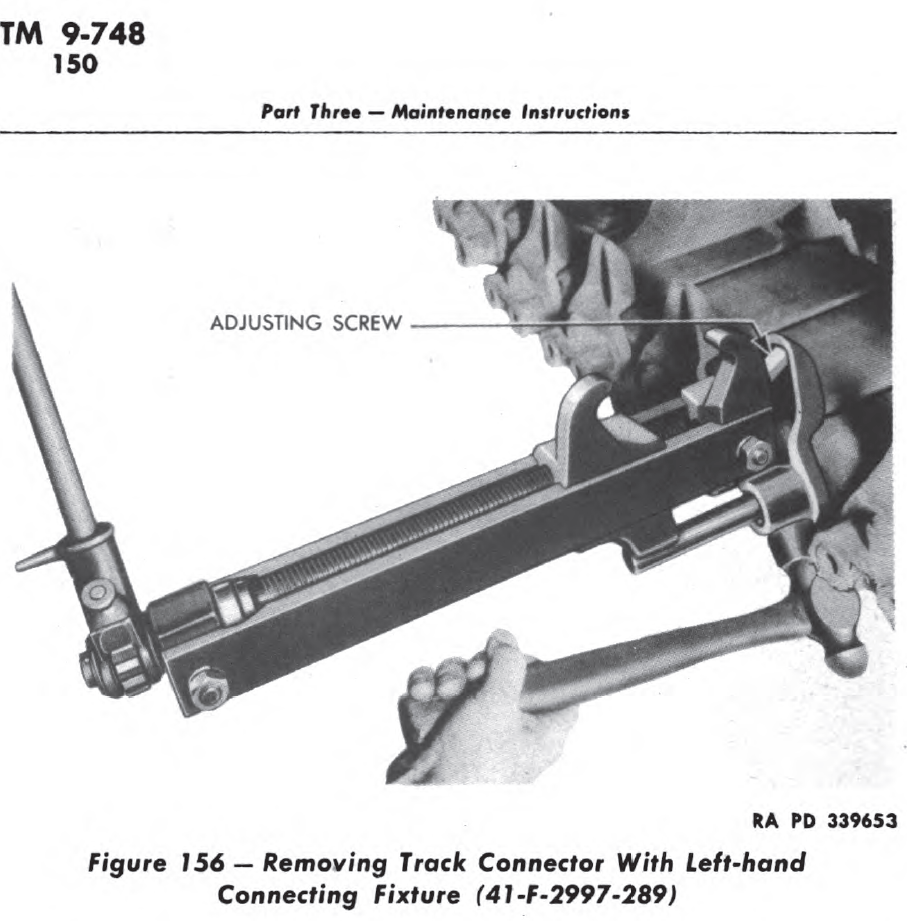

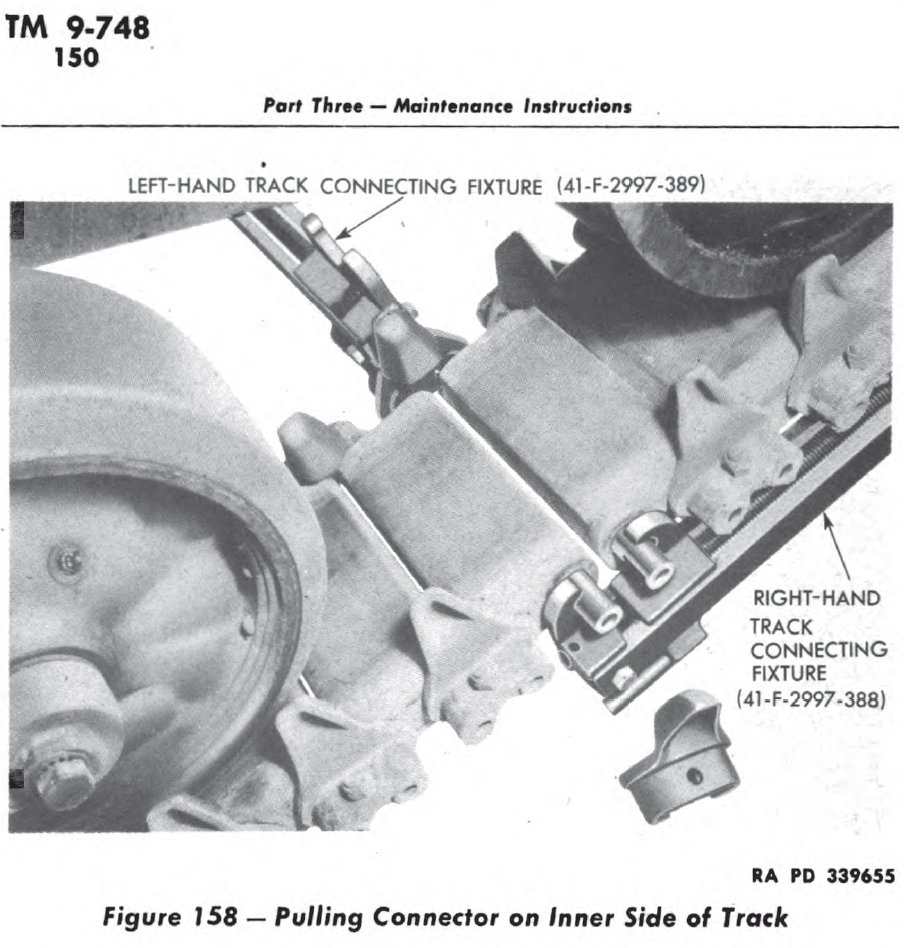

Fig 158 must be for INSTALLING not pulling — when installed, there is no room BEHIND for the jaws of the fixture to be placed. And the fixture draws the pins together, because gravity pulls them apart.

Fig 156 – Don’t understand how whacking it with a hammer will draw the tracks together so you can slip the connector over the pins. Neither does it make sense if this is a mis-labeled illustration for removing. And is there enough clearance on the inner side of the track to use the fixture in the orientation shown?

Is there something not stated about using the left & right fixtures simultaneously?

The fixture has a locating pin that goes into a hole in the track pin. So you have to drill out the frozen crud that is clogging the track pin hole before you can use the fixture? Seems like a poor design.

VVSS track width: 16 inches.

HVSS track width: 23 inches.

HVSS is not “double the track width”

Ouch, that one is pretty obvious!

What was the reason they used copper rings inside the track links?

Paul

Good question, I’m not sure, let me ask around.

Thanks for checking out the site!