Gallery V, More Sherman Photos, more Comments, Maybe Fewer Resolutions.

More images, with captions, most high res, some sherman chassis based things as well.

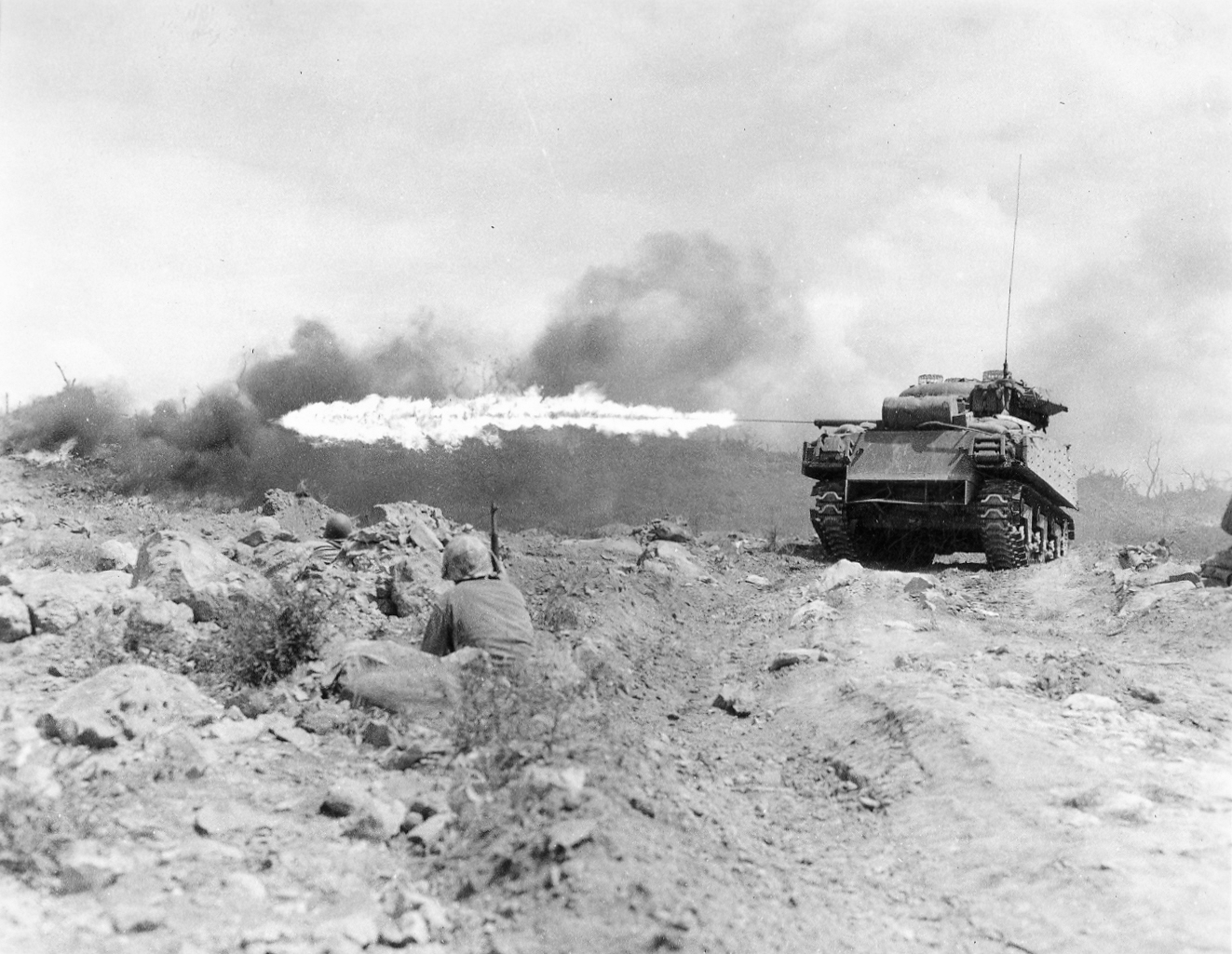

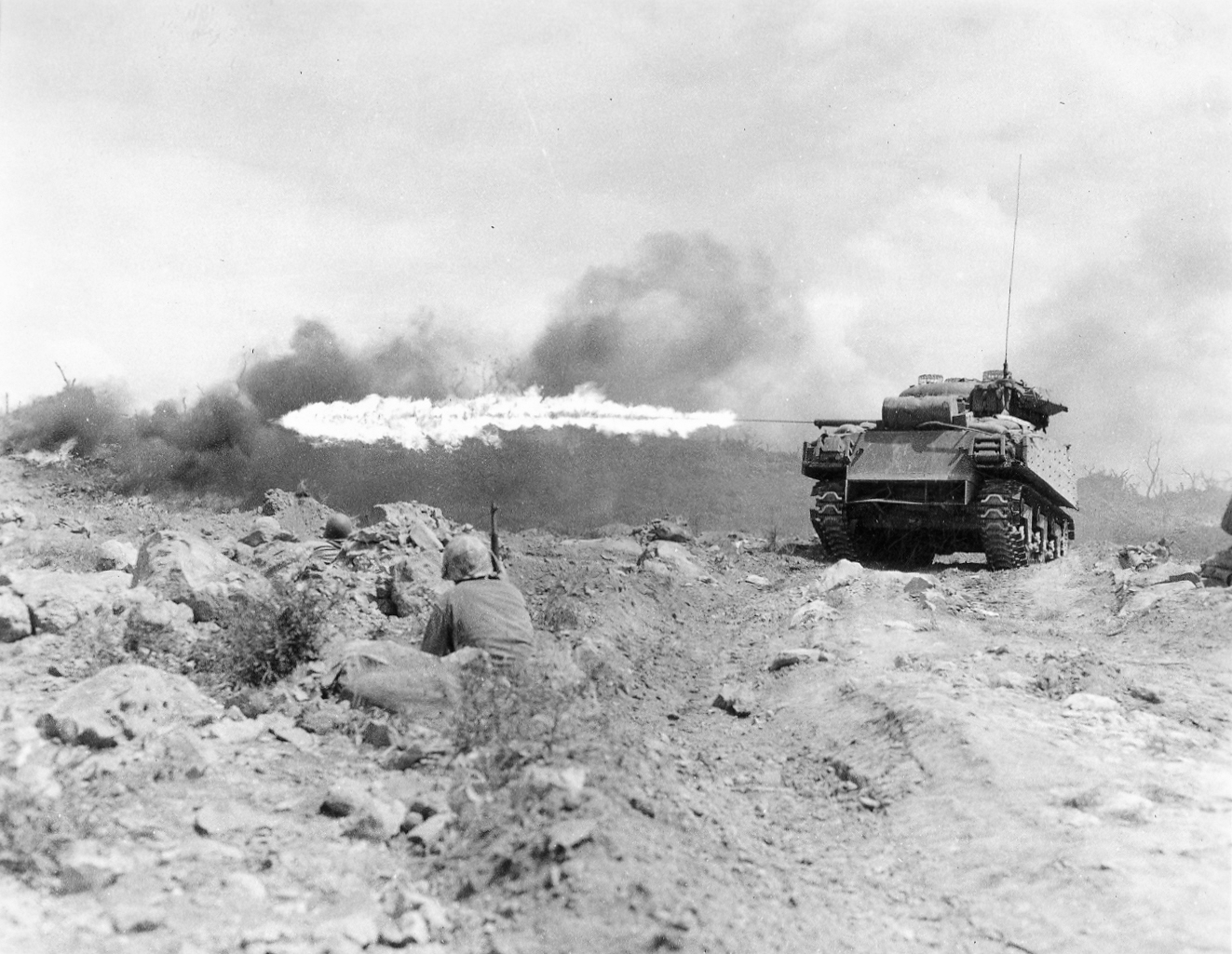

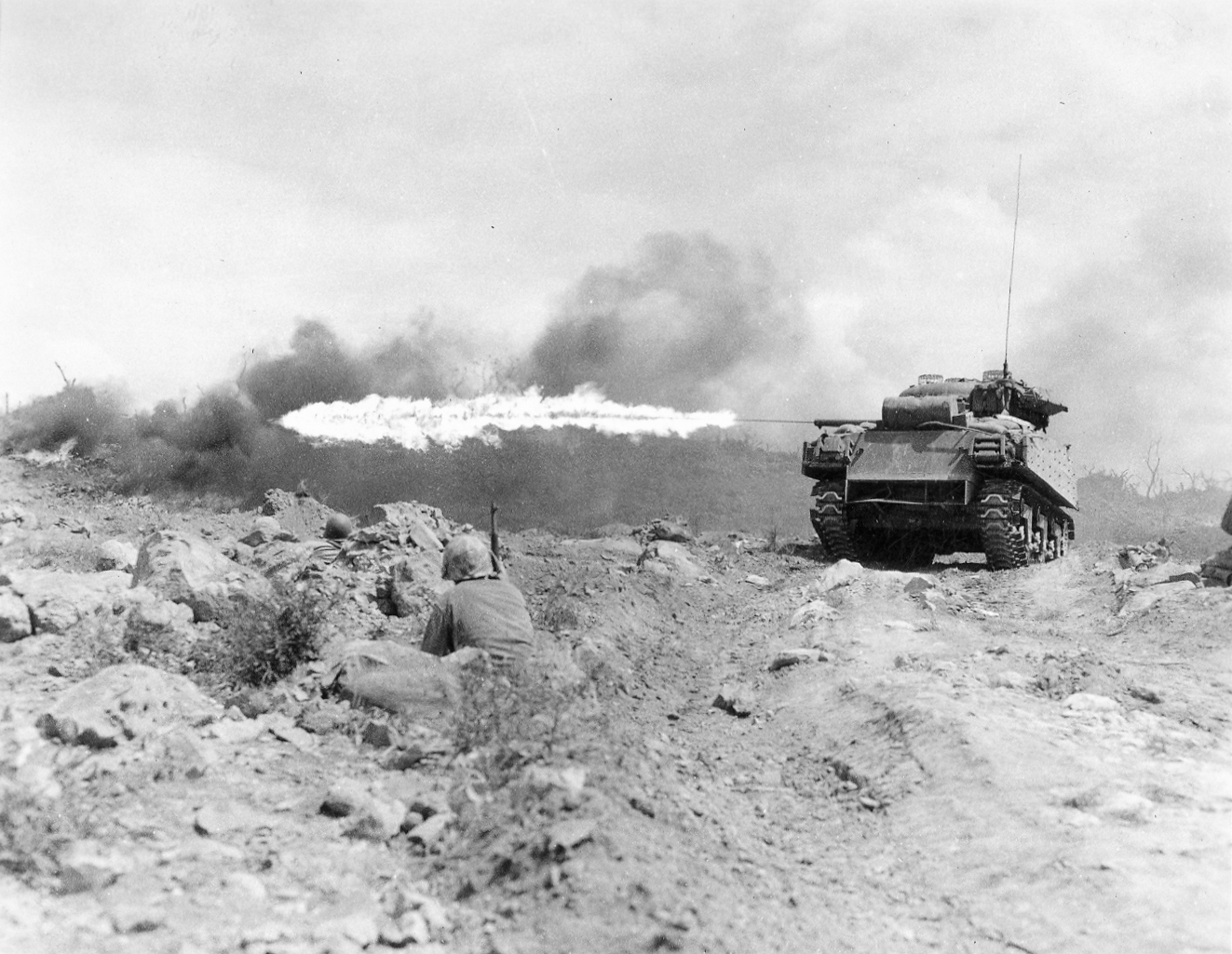

Marine supporting an M4A2 maybe on Saipan

Marine supporting an M4A2 maybe on Saipan

Thanks again Ron!

So I made a few things on CafePress, and decided if my and I were willing to wear them, other may want to as well, so here they are. I do not make any money on these, I just made them up for personal use, and decided to post them here, just in case.

Anyway, if you see a stout middle aged dude in Marin wearing a hat or t-Shirt, it’s probably me.

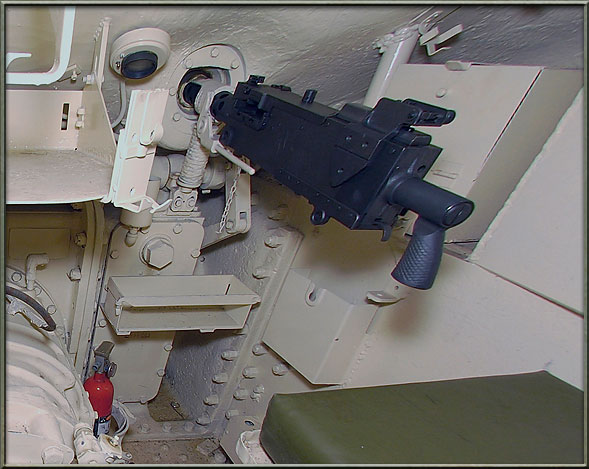

The US Army issued early Sherman tanks with a single Thompson M1928A1 .45 caliber submachine gun. The tank also had two boxes to hold a total to twelve hand grenades of various types. Two smoke and two thermite grenades were kept in a box on the left side turret wall, and there was another box under the gunner seat that held 2 smokes grenades, 4 M2 fragmentation grenades, and 2 M3 offensive grenades. The tank also had a pair of M1919A4 machine guns and the M2 HB that could be mounted on the pair of tripods issued with the tank. They had 600 rounds of .45 ACP and 4750 rounds of .30 caliber, and 300 rounds for the M2 HB. This was what the tank could officially carry, but crews often carried more .30 caliber rounds, and even main gun ammo on the floor of the tank, and they would also store small arms ammo on the outside of the tank

Later versions of the Sherman were issued with a slightly different setup. The single M1928A1 Thompson was replaced with 5, M3 submachine guns. The other major change was, all the machine guns were provided with more ammo, 600 .50, 6250 .30, and the same 600 rounds of .45 for the new SMGs. The tank was also issued with a small number of spare parts that commonly broke on all the weapons and specialized tools to service the tanks weapons.

In all cases, each member of the Sherman crew would have been issued a M1911A1 pistol as a side arm, but that was their personal weapon, and not part of the tanks gear.

Let’s talk about these weapons a little, first the Machineguns.

M2 HB .50 caliber machine gun: Who doesn’t know about this machine gun, developed before WWII, it was a legend by the end of the war and is still being used. It saw use everywhere the US Military fought. If it could mount a heavy Machine gun or guns, the Americans put one of these on it. The Sherman had one, The M16 halftrack had four, the P-47 Thunderbolt had eight! They used them on ships, jeeps, aircraft, with the infantry, and as AA guns. There is a reason this machine gun, designed by maybe the greatest firearms inventor of all time, John Browning, is still in use, its a great gun, firing a pretty good round. It’s so well liked, slightly improved version still serve with the US Military and to many other Nations around the world to list here.

The versions issued on the Sherman had a 450 to 550 RPM, and a quick change barrel that still required it to have its headspace adjusted, so not all that quick. Someone who knew what they were doing could keep the barrel from overheating by firing in short controlled bursts though, and on the Sherman, since the ammo supply was fairly small, you had to use it sparingly anyway. The machine gun would rarely leave the tank, were the lighter M1919s might be pulled and mounted on a tripod for some reason, if the crew had to fight on foot, or to setup around a perimeter at night maybe. In the Pacific, they would build a bunker under the tank and have a sandbagged enclosure at the front they could crawl into with the .30 mounted on a tripod.

M1919A4 .30 caliber machine gun: The Sherman crew was provided with two, sometimes three of these guns. They like their bigger, little brother, the M2, were designed by John Browning. For The US Military in WWII and Korea, .30 caliber meant the 30-06 cartridge. This was a pretty decent round as .30 caliber rounds go, and would serve as the Army rifle and light/medium machine gun chambering until the adoption of the 7.62 NATO round. This gun spat rounds at between 450 and 550 round per minute and it was a reliable and well liked gun. If it had a flaw, it was it was not easy to swap barrels on, for the same reasons as the M2, and it was a tad heavy for a light/medium machine gun, these are minor flaws for a vehicle mounted MG, though, in longer fights, the co-ax M1919 would burn out their barrels before the fighting was over.

The M1919 served with the US Army, and Marine Corps well into the 50s, they were eventually replaced by the M60 machine gun. These machine guns have a long and well recorded history, and my goal here is to talk about them without causing any new myths or bad information.

Now let’s talk about the Submachine guns.

M1928A1, .45 ACP submachine gun: This SMG is another American Classic, and it was a classic by WWII all on its own. Originally developed for use in WWI, it missed the war, and any Military contracts, but the gun was sold on the civilian market. Enough sales trickled in from a few small government and police agencies, along with foreign sales to keep Auto-Ordnance alive between wars. The weapon was sensationalized by the media after it was used by prohibition era gangsters and a few notable regular criminals, and this inspired some of the nation’s first federal gun control laws. In 1934 the National Firearms Act went into effect after being passed by Congress. It limited the sale of Machine guns to civilians and made the ones already in Civilian hands have to be licensed.

There was already one huge limiting factor on Thompson sales, if you were not a government agency; you had to be pretty rich to buy one. Sure, a few criminals were, but what normal Joe of the 1920s could spend $200 bucks on a machine gun when a new car cost around $400? That 200 bucks was for the basic 1921 m model with 1 magazine. When you started adding things like the wood front pistol grip, deluxe wood furniture and drum magazines and fancy cases, the price could run into luxury car range.

The M1928A1 was not all the different from the M1921, and still used the odd Blish lock and could still take the drum magazines but had dispensed with the front pistol grip. If it had a drawback it was that it was large and heavy for a SMG, but you would think this would help control it.

The Army would go on to have even simpler version of this SMG produced, but as far as I know only the M1928A1 was issued with early to mid production Sherman tanks.

M3 and M3A1 .45 ACP submachine gun: This SMG was designed to be the easiest to manufacture and cheapest SMG that could still perform as well as the M1928A1 and the M3 was born. After some use, the M3A1 came about to solve all the problems with the basic M3. The M3 looks a little like a grease gun, so that name stuck, and the weapon would go on to serve into the 1990s as tank crewmen’s weapon.

The M3A1 was a simple no nonsense weapon that filled the tank crewmen dismounted weapon role fairly well, and that’s why it no one bothered to replace the thing. It was replaced with the MP5.

From the Sherman crewman perspective, I bet they’d say, five M3A1s is better than one M1928A1.

Next up, let’s talk about the pistol.

So much has been said about the 1911, I’m not going to say much, but I’ll note for those who don’t know, John Browning designed it too. I will say this, it is not the finest handgun ever produced, nor is it even close to the worst. It is probably the most popular handgun in America, and I own two. What it was, was a reliable, tested, accurate enough handgun for soldiers, pilots, officers or anyone else who needed one. Like all handguns, it should be viewed as a last resort, and the M3A1 or M1928A1 would be more useful in all but the most close of encounters for a tank crewman.

It also may be the most written about firearm ever as well, since every issue of Guns&Ammo, Guns, Shooting, etc. had at least two stories about some variant of the gun. I would be surprised if it isn’t the most popular handgun type in the United States. The only guns that seem to rival it are made by Glock.

. . .

. . .

Now so far, we’ve only been talking about the weaponry issued with the tank or to the crew. Soldiers and marines being soldiers and marines means as soon as they were out of an environment where the tank the tank was being inspected on a regular basis they would have started acquiring extra things for the tank. Crews of early Shermans probably worked pretty hard to get more Thompson SMGs, or used captured German or ones; the MP-40 with its folding stock was nice for tank use. I’m sure they stuffed extra grenades all over the tank along with extra .30 cal and .50 cal ammo. Depending on unit discipline and how aware they were of the risk, some crews might have carried extra main gun ammunition as well, but unprotected main gun rounds were very dangerous to the crew. It wouldn’t be impossible for something like an M1 Garand or M1 Carbine to make an appearance as well. Mounting extra machine guns on the turret for the loader was a fairly popular modification as well.

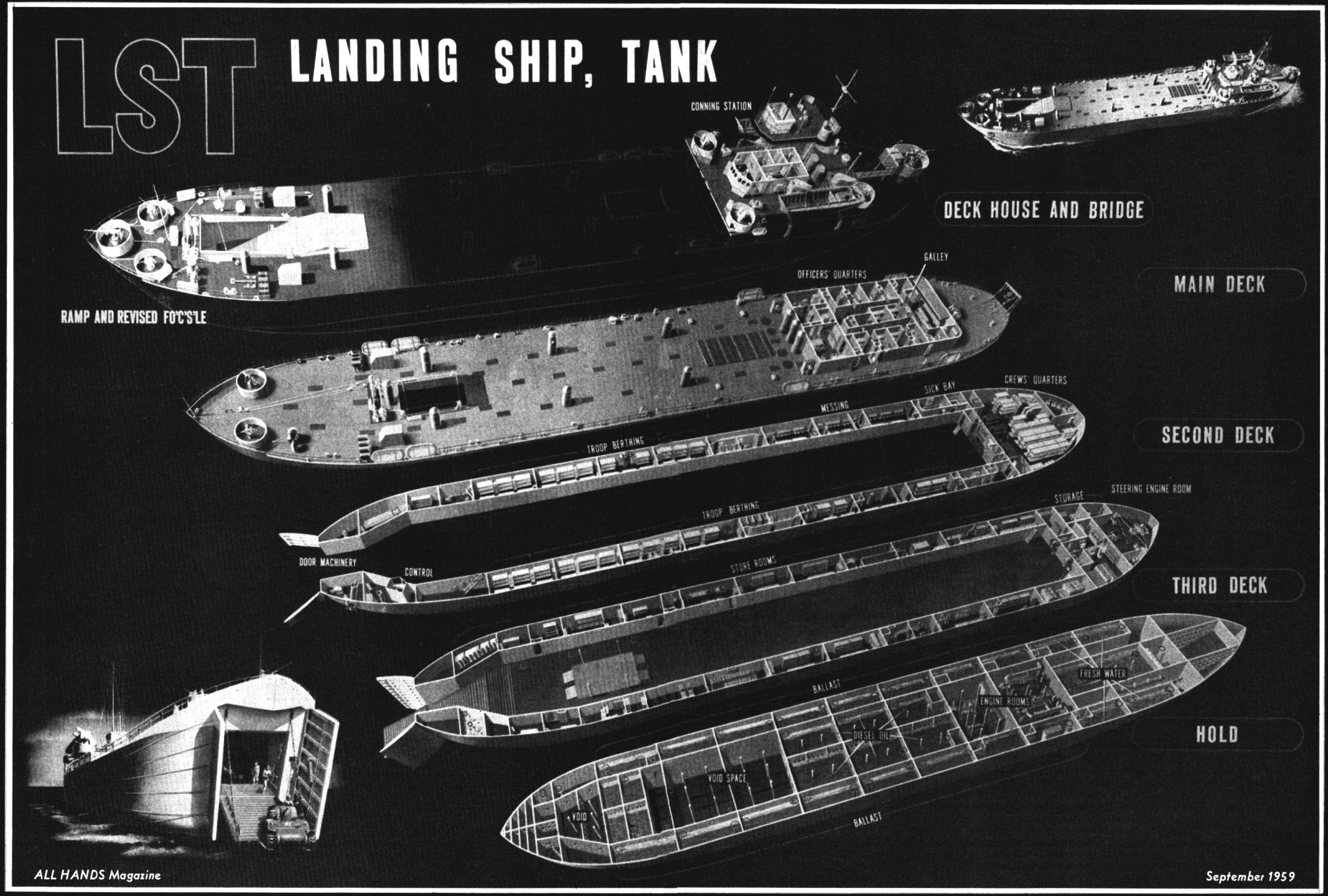

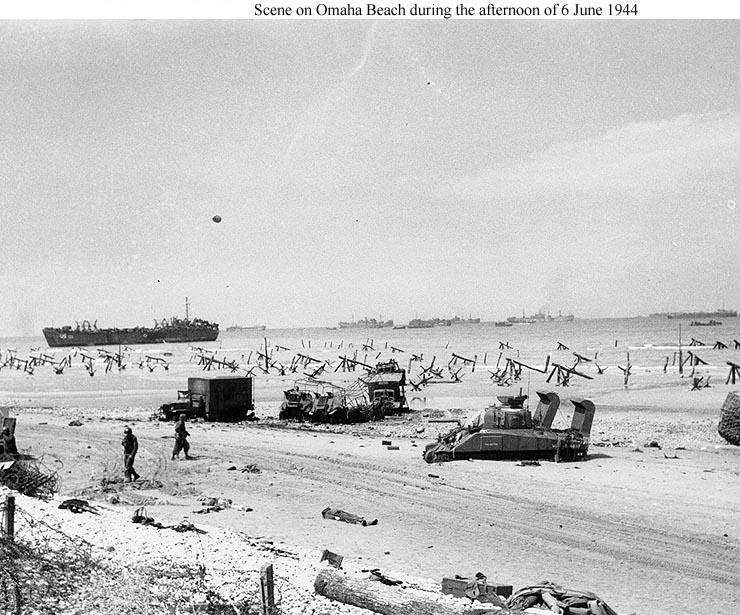

When most people think about a tank being used in a beach assault, they think the Duplex Drive Sherman, or tanks getting delivered by LCM or LCT. There were many other specialized landing craft, and they all had similar flaws. The main being they were small, and not really capable of long ocean voyages. They also couldn’t haul a useful amount of cargo for use in an efficient shipping system. The LST or Landing Ship Tank was the solution.

The LST a large ocean-going vessel, and though they reputed to have a horrible ride, were capable of crossing the Pacific or Atlantic oceans with their own fuel stores. There were several classes of LST but the differences between them were fairly minor unless you want to get into the British made LSTs, but we’ll do that later. For our purposes we are going to use LST-808 as our example, she participated in Iwo Jima and Okinawa. She was lost to a Kamikaze towards the end of the war.

Class: LST-542

Displacement:

1,625 tons

4,080 tons (sea-going draft w/1675 ton load)

2,366 tons (beaching displacement)

Length: 328 feet Beam: 50 feet

Draft:

Light: 2′ 4″ front, 7′ 6″ aft

Sea-going: 8′ 3″ front, 14′ 1″ aft

Landing: 3′ 11″ front, 9’ 10″ aft (landing w/500 ton load)

Limiting: 11′ 2″

Maximum navigation: 14′ 1″

Speed: 11.6 knots. (trial) Endurance: 24,000 miles at 9kts, while displacing 3960 tons

Complement:

13 officers, 104 enlisted

Troop Accommodations:

16 officers, 147 enlisted

Boats: 2 LCVP

Cargo Capacity: (varied with mission – payloads between 1600 and 1900 tons)

Typical loads:

One Landing Craft Tank (LCT), tanks, wheeled and tracked vehicles, artillery, construction equipment and military supplies. A ramp or elevator forward allowed vehicles access to tank deck from the main deck

Additional capacity included sectional pontoons carried on each side of vessel amidships, to either build Rhino Barges or use as causeways. Married to the bow ramp, the causeways would enable payloads to be delivered ashore from deeper water or where a beachhead would not allow the vessel to be grounded forward after ballasting

Armament: 2 – Twin 40mm gun mounts w/Mk. 51 directors, 4 – Single 40mm gun mounts, 12- Single 20mm gun mounts

Fuel Capacity: Diesel 4,300 Bbls (approximately 180600 gallons of fuel.)

Propulsion: Two General Motors 12-567A, 900hp Diesel engines, Single Falk Main Reduction Gears

Two propellers, 1700shp, Twin rudders

Three Diesel-drive 100Kw 230V D.C. Ship’s Service Generators

As you can see from the specifications, these ships, were pretty big and over a football field long. The tank deck had a massive capacity; it could take up to 20 Sherman tanks, 39 M3/M5 light tanks or 70 trucks or anything else that would fit up to 1900 tons. Not only did they have the ability to carry the vehicles, there were accommodations aboard for the crews and troops that would be riding the ship.

The LSTs were longships, and their front hull had a much shallower draft than the rear. The front of the hull was made up from a pair of huge doors that opened out, and behind them was a ramp that was dropped. If shore conditions were right, the ramp could be dropped in the shallow surf and vehicles drove right off and onto the beach. If beach conditions were not right, like a sandbar or reef stood in the way, they could use floating pontoon docks to make a causeway that tanks or anything else could drive to shore on. These causeways would be held in place by LCMs. The LST could carry large numbers of the pontoons as deck cargo. They would know ahead of time what the beach conditions were going to be and what they would need to bring. This ingenious system was something only the allies, and specifically, the US and the UK came up with. Nazis were not good at logistics.

The LST used a system of pumps to fill or pump out large numbers of compartments all around the hull to raise or lower the ship in the water. When they were about to beach the front of the ship, the would need to be as high in the water as they could, but at sea, they would want many of the void spaces flooded to keep the flat-bottomed LST from rolling around so much in even mild weather. Even loaded up and with the ballast spaces as full as was safe, the LST’s still had a less than ideal ride. Very few were lost to weather though. I don’t have a good breakdown of the numbers but the US had 933 LST(2) and 26 were lost to enemy action. They lost another 13 to fires, collisions, explosions, storms, and groundings. The rest were worked to death in the decades after the war with a few exceptions.

One of those exceptions is LST-325, she is still around, and a museum ship, but the best kind of museum ship, the kind that can still get underway! Check out LST-325s webpage, they may be coming to a city near you!

Being an LST captain was not something a career naval officer would have wanted, and most officers were reservists. Some joined their ship while it was being built, and would stay with it until wars end, or it was sunk. The LSTs were not the worst ships to serve on, they had a nicely appointed galley, and served with the same men the whole war, including the enlisted crew. The LST proved to be pretty safe and durable because of how they were built, with a lot of reserve buoyancy. They also had the capacity to produce a lot of fresh water.

The tank deck had to be ventilated so the tanks could be run, early LSTs had hoses that were hooked up the tanks or other vehicles exhaust. That setup did not work well, so twelve, eight-foot-tall ventilation stacks, with a fan in each were installed. These could clear the tank deck of vehicle exhaust even with the bow doors closed. There was an elevator on early LSTs, but it was slow and not all that reliable, so it was replaced with a simple hinged ramp.

The ships were also well appointed with shops including a machine shop with a full complement of metalworking tools, and there was probably an electrical and hydraulic shop as well. The Captain would be a full Lieutenant of the Navy, and the XO a JG. As mentioned before in many cases these men joined the ship while it was being finished, right after they finished they Navy Officer or Boot Camp, and a few cases specialty schools. They would work with the builder to get their LST working and get it commissioned and then take it out, often right to a combat area but they might stay stateside for more training.

The Army Armor base at Fort Knox built a replica of a tank deck on the base so tank crews could practice loading and offloading. The US Navy built 1051 LSTs were built in the US. Most of them served with the US, but some went to the UK, and the Greeks even operated some. After the war, the surplus LSTs were bought up by commercial interests right away. They are very useful for delivering heavy cargo to areas with no heavy port facilities. A few survive to this day.

Now for my obligatory section on why this ship was something the Germans had nothing like. The Germans also lacked the ability to build all the different landing craft the allies used in their multiple successful amphibious landings. Germany was short of resources, and even if they had been given the plans for the LST and all the various other landing craft you need to land on an enemy shore, they didn’t have the naval construction capacity or natural resources to produce them. Maybe if they had not built their silly battleships, but that gets to the other problem, they never achieved air superiority, nor naval supremacy in a time frame they would have needed to pull off operation sea lion. Nazi Germany was bad at boats and planes, but great at propaganda, some people still buy into even today.

The Sherman tank, like anything man produces, was series of compromises to meet the US Army’s design specifications. The Sherman was also designed by a country with little tank making experience. The British, who were already at war, helped a great deal with the Sherman design with feedback from their combat experience. Some of the lessons learned about the Lee/Grant design did not come in time to affect the very early Sherman design, but improvements made it into the production line fairly fast.

Let’s start with the early Shermans, and by early, I mean all small hatch hull tanks. The automotive systems on all the early Shermans were good. All the major issues with the four major power plants had been resolved in the Lee. This is true of on the early VVSS, it was replaced with the heavy duty VVSS used first on the M3A4. The narrow tracks were a flaw, in soft terrain and mud the Sherman with VVSS, and 16-inch tracks, was at a disadvantage compared to the Pather, but this flaw was resolved in two ways before the end of the war. The first was duckbill end connectors on the 16-inch tracks, lowering ground pressure, and then HVSS came along in late 44, with 23 inch wide tracks that resolved the problem completely, the HVSS Sherman could go anywhere a Panther went, without risk of breaking down constantly.

The Powertrain was so good it remained largely unchanged throughout the Sherman production run, I would say it was pretty close to flawless. The very early Shermans had direct vision ports, this was solved pretty quickly on the production line in most cases, and the tanks produced with the DV ports had upgrades that could be installed in the field to solve the problem of them being a weak point in the frontal armor. The complicated multi-piece front plate was not great, since the welds took extra time to manufacture, and they were ballistic weak spots as well; it was simplified on late production small hatch tanks by reducing the number of plates and was replaced by a single plate when they updated the hull with the large driver and co-drivers hatches.

The 75mm M3 gun was good; though some would argue it was a flaw, based on its lack of ability to pen the front of the Panther and Tiger tanks. For the first year or more, the Sherman saw combat its gun was very good for both anti-tank work and infantry support. German tanks, even in the mid part of the war were relatively rare compared to AT guns, and the 75 M3 was a much better gun for taking those out. The US Army did see a need to improve the AT performance and began working on installing the M1 76mm gun into the Sherman, and they began this process before the Tiger or Panther showed up. By the time the Panther showed up in large numbers, Shermans with 76mm guns were showing up in large numbers as well. So this flaw was addressed as well, though, not fully, since the M1A1 gun was not all that it was cracked up to be. The truth is, by the time the US was facing Panthers on a regular basis, the crews in them were so green, and the tank itself so complicated and hard to fight, even Sherman 75s had little trouble handling them.

Yes, its early ammo storage was a flaw, storing ammo in the sponsons, and all around the base of the turret basket made it easy to brew the tank up with an ammo fire. They figured this out, and changed the ammo configuration and put it all in armored boxes. Most tanks already issued received these changes in kit form. When the large hatch hull went into production, for the most part, these tanks got wet storage in the hull, under the turret basket, with water jackets. This location proved to be a very good place for the ammo, and fires in penetrated Shermans went down drastically. The location was far more important than the wet part of the storage, and it was dropped post-war. Some crews objected to the changes in ammo storage, a pre quick fix Sherman with 12 to 14 ready rounds within easy reach of the loader could pump out a very large volume of fire for a fairly long time, the new ammo layout really slowed the rate of fire down in a sustained fight. Because of this, some crews ignored the new ammo regulations and stored as much loose ammo as they could in the turret basket. These crews were willing to risk the higher chance of catastrophic fire, to keep that higher sustained rate of fire.

Some like to say it’s reliance on gas engines was a flaw, most of the people who like to point this out don’t understand that the Sherman had a diesel version, and American gas-powered tanks were no more likely to burn than anyone’s gas-powered tanks and were much less prone to fire than German tanks like the Panzer IV, it was the worst of the war, all German tanks were gas powered as well. Hell for most of its life, the Panther didn’t need any help from the allies to light itself on fire. I do not call the US Armies reliance on gas a flaw, it was a choice, the US Army could have kept all the A2s if they wanted diesel tanks. In fact, from the automotive standpoint all the motors the Sherman used, even the A57 multibank, were more reliable than any motor the Germans produced for use in a tank.

The armor, here you can make a pretty good argument the tank was flawed. It had better armor than all other mediums in its weight class, but that, of course, won’t save it from guns like 75mm L70 or the 88mm L71 guns. No tank in its weight class could, nor could the heavier German tanks like the Tiger or Panther for that matter. In most cases, medium tanks don’t have enough room left in their design to take much more weight of armor. This is one of the things that ruined the Panther, all the extra weight from armor, but no upgrades to the powertrain.

Now, the Sherman design is a special case, the powertrain, and suspension were so well designed; they could take the extra weight of more armor, without compromising reliability. The Jumbo, and all the field mods, including the field mod Jumbos like Thunderbolt VII, an M4A3 76W HVSS tank, that had extra armor cut from knocked out Shermans onto its hull and turret, prove it. The Army was aware it could take these upgrades, as the Jumbo program, and their toying with add-on armor kits shows. Even the Jumbo couldn’t stand up to the 88L71 for long, and more armor than the jumbo tanks had, would have compromised the tanks automotive bits. So the armor was good enough, because armor that could stop the big AT guns it was facing was not practical, and would have caused automotive problems. But the basic Sherman could have had significantly thicker armor without affecting the Shermans reliability or producibility. This would have made an already good tank better, but there also may be reasons why they couldn’t, the War Production Board always had a say in these things, maybe they didn’t want to shift over more steel production when they were desperate for it in the Landing Craft/Ship program, when talking about American War production, you can never consider just that item, because they didn’t every program fought for priority in the system.

No, to really get into the Shermans flaws, you have to look at the things that could not be addressed with simple upgrades. The tanks height, front drive, and sponsons, and all these had to wait until the T20 series ended in the M26. The front drive and suspension from the M2/M3 series got carried over to the M4 series because they hadn’t even solved the turret ring problem, so they really hadn’t spent much time looking into rear drive. Men and women were designing these tanks and their parts on drafting tables using slide rules. The Greatest Generation and the one before they were so good at math it’s mind-boggling. The tanks designed to replace the Sherman all used rear drive, with the motor, tranny as one big unit in the rear of the hull. These designs also eventually got torsion bar suspension, but it was deemed so little of an improvement in the M4 series as to not be worth changing production lines, but it was good for the newer tanks. There is some debate about torsion bars being the best way to go, the US Army said yes, and every tank up until and including the M1 Abrams use torsion bars. This was not the only choice, the British used improved, but very Sherman like Bogie systems on the Centurion and they upgraded that tank for decades. The torsion bar system takes up space in the hull, bogie type systems don’t and bolt on suspension is easy to repair, torsion bar systems are notoriously not easy to fix on any tank that has them. I’ve read M48 repair crews in Vietnam would use C4 to blow the axle stubs out of the hull, instead of doing it the normal way, to save time.

The Shermans tallness, one of its real flaws, though one that’s always exaggerated, was also caused by the Shermans front-drive layout. This was because this layout required a drive shaft from the motor, to the tranny to run through the fighting compartment, thus forcing the turret basket up and making the tank taller, and in the Shermans case the first engine choice the R975 was a big motor, and forced a large tall engine compartment on the design. There was not much that could have been done to solve this problem short of putting one of the T20 series into production, but they wouldn’t have produced a tank that was really much better. This was a design flaw all the German cats, and pretty all German tanks had. They don’t have the R975 as a reason, they were just bad at engine layout and cooling systems and wasted a lot of space there.

The final flaw is a minor one, the hull having sponsons added area that had to be protected with armor. Had they been eliminated, their weight in armor could have been added to the front of the hull and turret making for slightly more armor, but a much more cramped tank. This is a pretty minor flaw overall, and the Sherman would be the last US tank design to have them.

So overall all, the majority of the Shermans flaws were solved over its production life. The ones that couldn’t be were resolved in the next tank design. I have to say, all in all, that’s a very small list of serious flaws and it is far outweighed by the Shermans pluses. This does nothing but reinforces my view that the Sherman tank was the best tank of the war.

If you came by this article from that terrible Cracked article, 5 Things about War you thought were true because of War movies, forget the garbage you just exposed yourself to and stick around and read up on the most important allied tank of the war, the M4 Medium Tank, AKA the Sherman.

Start here: The Conclusions: Was The Sherman Good Enough? Hell, Yes, It Was!

Then stick around, you can actually learn something from this site.

This dozer blade came in kit form and could be installed on any Sherman. They came two to a crate, an M1 and an M1A1 each per crate. The difference between a M1 and an M1A1 Dozer blade was pretty minor, and an M1A1 dozer blade was universal, but the M1 blade only worked on Shermans with VVSS. This is because the M1A1 blade was wider. Here is some data on the blades. The reason the wider blade worked on the narrower VVSS tanks was because the kit came with spacers to fill the gap left by the wider A1 blade when used on a VVSS tank.

Blade Data

Blade Height: —————————————————————————————-48 inches

Overall width M1:———————————————————————————124 inches

Overall width M1A1:——————————————————————————138 inches

Added weight to tank M1:————————————————————————-7100 lbs.

Added weight to tank M1A1:———————————————————————-7400 lbs.

Lift height of blade M1:———————————————————————18 to 30 inches

Lift height of blade M1A1:——————————————————————18 to 42 inches

Lift Load, M1:——————————————————————————————- 4000lbs

Lift Load M1A1:—————————————————————————————–5000lbs

The TM for the kit makes it sound like it was installed on tanks at the Depot Level and then the tank was issued to a unit with the blade kit installed and ready to go. After reading through the tech manual, it could be done by the tank crew without to much trouble, though a small crane would be nice for the installation of the hydraulic cylinder, but that seems like it would be a rare occurrence. If the kit had a drawback, it was that the blade blocked the bow Machine gun.

The kit broke down into several major parts groups.

Hydraulic Group: Was made up from external and internal parts that were a part of the Hydraulic system including the pump, an oil reservoir, and all the brackets to install these parts. There were also hoses and fasteners of various types. It also included a special wide angle periscope for the driver. Once

To install these parts a few things had to be removed from the interior. As this pictures show, the pump and tank assembly was fairly large. Essentially the tray for the spare periscope head box and the box had to be removed. The several brackets and guards had to be removed, and then the generator itself and its mount had to be pulled. It also involves disconnecting the transmission side of the propeller shaft, and installing a new pulley on it to run the hydraulic pump from. Once everything was installed, it did not impede the crew any more than when it wasn’t there since nothing took up the space right above the transmission.

A few parts from the hydraulic group did get installed outside the tank, the hydraulic hose, run through the left headlight mount. A guard for the hose and a cable running from a handle on the inside, used to jettison the blade in an emergency. All these parts are universal to all models of Sherman, though a few brackets could require a little modification for everything to fit right do to the way some hoses and belts were run.

The hydraulic jack and the framework attacking it to the tanks tow points on the front of the tank are also in the hydraulic group. There were several bracket sets for use with the different kinds of differential housing the tanks could have. There was a cover assembly/bracket to protect the mount, and hoses, and help position the jack

Suspension Mounting Bracket Group: This group used already existing bolt holes in the suspension to make installation easier. Each kit came with brackets to make it work with VVSS or HVSS. The VVSS bracket could be adapted to work with either the M1 or M1A1 blades, the HVSS Brackets could only be used with M1A1 blades, because the M1A1 blade was wider to accommodate the wider HVSS. This bracket and had the pivot points for the blade.

The VVSS mounts used a replacement suspension cap built onto the blade mounting bracket, and another replacement cap with bolt holes. Another part of the vertical suspension mounting bracket bolted to the unused return roller holes on the middle boggie assembly, the same one that used the built in replacement caps. The replacement cap with extra bolt holes replaced the cap in the front boggie assembly.

The HVSS mounts were simpler. You just removed four bolts in the first and second suspension arm supports and install the horizontal suspension mounting bracket with longer bolts and lock washers. This is a much easier install than the VVSS mounts, but neither seems overly hard.

Once you have the mounting brackets on, you get to move onto the…

Bulldozer Blade Group: This group is basically the blade and it arms that mount to the pivot points on the suspension brackets. This part of the job is where you could really lose fingers or toes. You need a nice flat area, the area you stated in hopefully, and then you drive the tank up to the blade, careful to keep it centered. The tank stops to feet from contact with the blade, and the driver raises the jack piston to the same as the connecting pin on the Blade group.

This is a multi-person Job, since the co-driver has to hold the quick release cable, in the release position, while the tank is driven into the Jack arms pivot points, and then let the pin close on the eye on the Jack head. The co-driver, while doing this is also guiding the tank into place on the blade arms. At this point the latches on the pivot points can be locked down, a large hammer may be needed and the quick disconnect cable fed into place and loosely connected in the interior of the tank. When it’s pulled the whole assemble will come lose and can be backed out of. You can see some of this in a video in the Shermans in motion section.

The final step would be installing the M14 periscope in the drivers position, filling the system with fluids and testing it out. The system was easy to use, and had dual controls, so the co-driver could operate the blade if the driver really needed both hands. The controls were a simple lever used to raise and lower the blade, raising it by hydraulic pressure, lowering it by cutting the hydro pressure and letting the weight of the blade bring it down. Removing the blade was as simple as pulling the quick release cable. If you planted the blade in the ground just right before release, so it wouldn’t move, you could drive the tank right back up to it, hammer the pivot point latches in place, put the pin in the jack and go.

I have to say this is a very impressive kit. It did make the tank a bit front heavy and probably shortened the life of the front springs, it was not a problem in any real way or the Army would have had modifications made to solve these problems. This kit saw prolific use with the US Army and Marines, and since it worked on any Sherman model, probably everyone else who used Shermans and could get their hands on it. This dozer kit was the most effective way of punching through hedgerows as well, working much better than the dedicated hedge row cutters. A tank company would get one dozer blade equipped tank into the HQ platoon, if there were enough kits to go around. There might be another one in the Battalion HQ platoon.

This report covers all the armored funnies, or specialty vehicles from Hedgerow cutters, DD tanks, and Crab modifications. Our interest from this article is the feedback on the Dozer blade setup.

This was the feedback on its combat use:

The tank dozer was employed extensively for numerous purposes commencing immediately after D-Day. Some of the missions for which the tank dozer was employed in the European Theater are outlined below:

(1) Shortly after D-Day a platoon of four tank dozers of the 741st Tank Battalion operating on the beaches under intense fire, removed beach obstacles, opened roads and pushed off beached landing vehicles.4

(2) The tank dozer was used to break through hedgerows, broaden existing gaps and gaps blown with explosive charges; and thereby facilitated the use of other than normal entrances through hedgerows.5

(3) Tank and gun emplacements were prepared.

(4) Roadblocks were cleared; and in addition, rubble, wrecked vehicles, and snow were removed, and craters filled. It was found necessary in many instances to provide a tank dozer for these purposes to work in conjunction with the roller type mine exploders in sweeping roads and shoulders.

(5) In connection with the Roer and Rhine River operations, bridge approaches were built, launching sites for LCM’s and LCVP’s and crane sites were prepared, and cuts dozed in the river dikes.

The Tank Dozer has the following merits and deficiencies:

(1) Merits:

(a) The tank dozer provides armored units with a standard vehicle that can be readily employed to reduce obstacles and assist in the advance of units or to assist in the preparation of defensive positions.

(b) Armor protection is provided for the crew.

(c) The tank dozer can also be employed as a fighter tank.

(d) The tank dozer installation is simple, reliable, and its maintenance demands are negligible.

(2) Deficiencies:

(a) The tank dozer installation overloads the front of the tank suspension system and increases bogie tire failures and suspension maintenance demands.

(b) The tank dozer installation materially limits the driver’s field of vision.

(c) There is insufficient clearance between the track and dozer blade arm to ensure safe operation with the addition of the standard 3-5/8 inch track extended end connectors.

(d) Sufficient dozer blade accessories were not available so that dozer blades salvaged from burned tanks could be readily reinstalled on other tanks.

I found this very interesting, please check out the Lone Sentry Web site, it’s a very informative place.

The source for this post was almost exclusively Tech Manual 9-719 Tank Mounting Bulldozer (M1 and M1A1). The TM can be found in our download section and the report on the lone Sentry.

Here’s a video from the army on how to install this dozer blade kit.

https://drive.google.com/open?id=0B5k30qNybbcZbm1HLTkwU1FUOWs