Post #70: Report on the New Weapons Board

I downloaded this PDF, Report on The New Weapons Board 1944, someplace, but since I don’t remember where I hosted it too. The report documents the feedback the troops gave to the board on the various weapons they demonstrated.

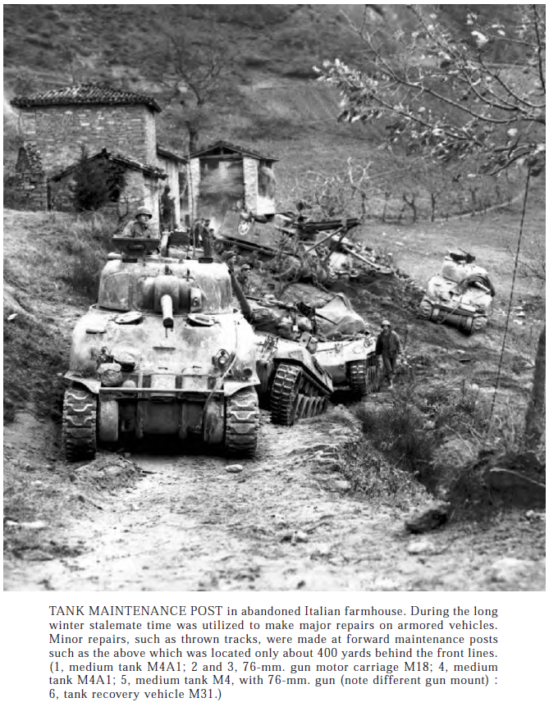

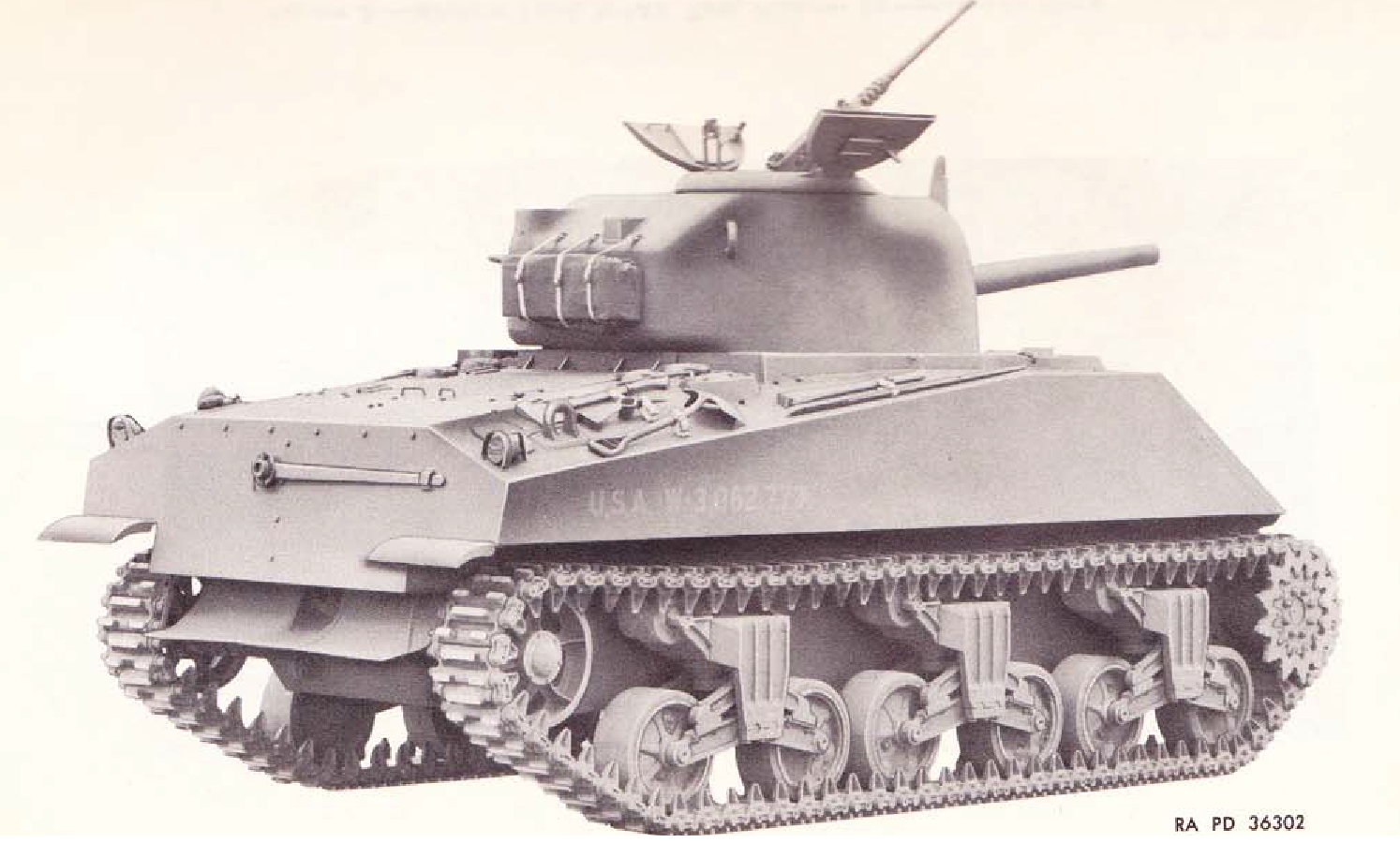

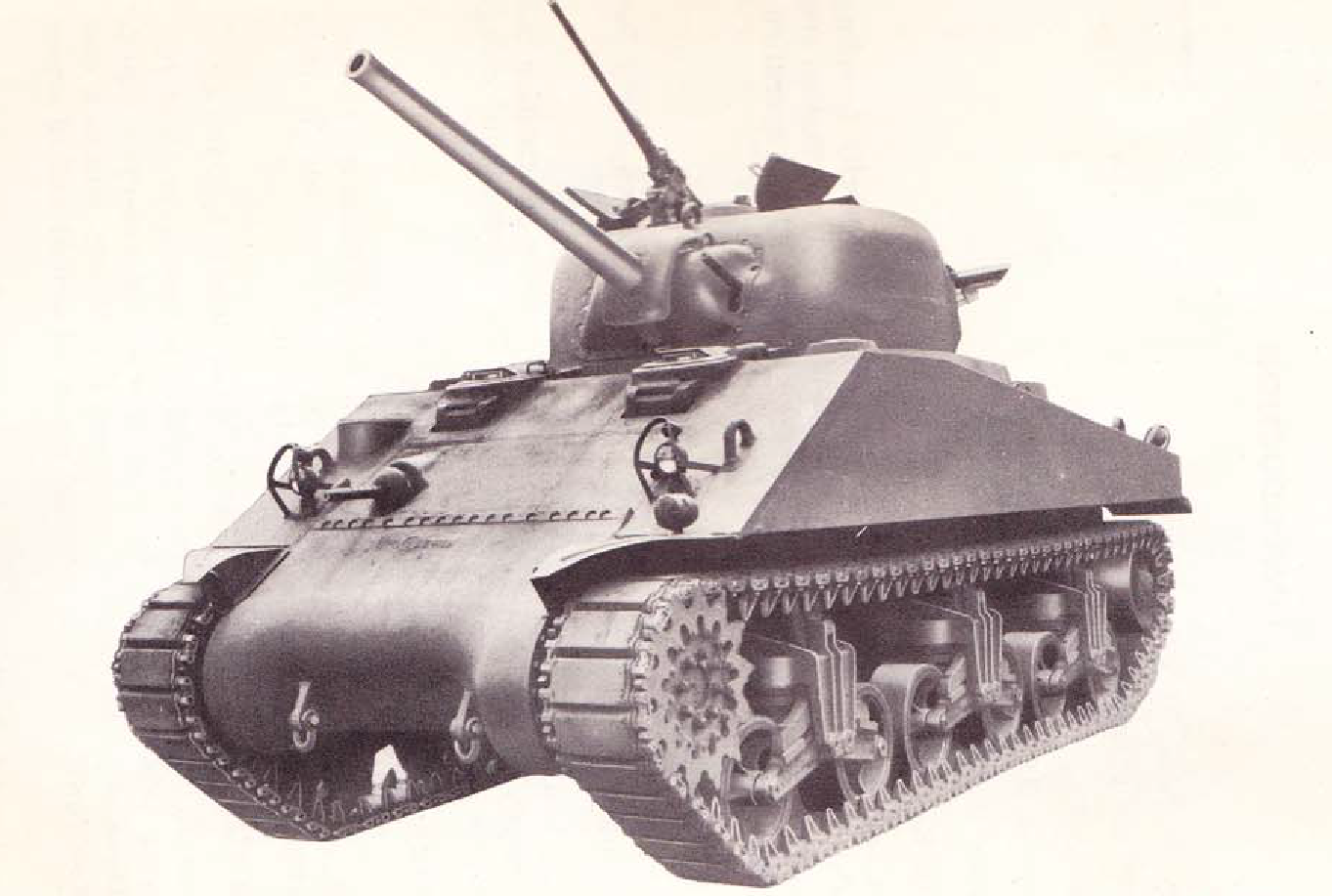

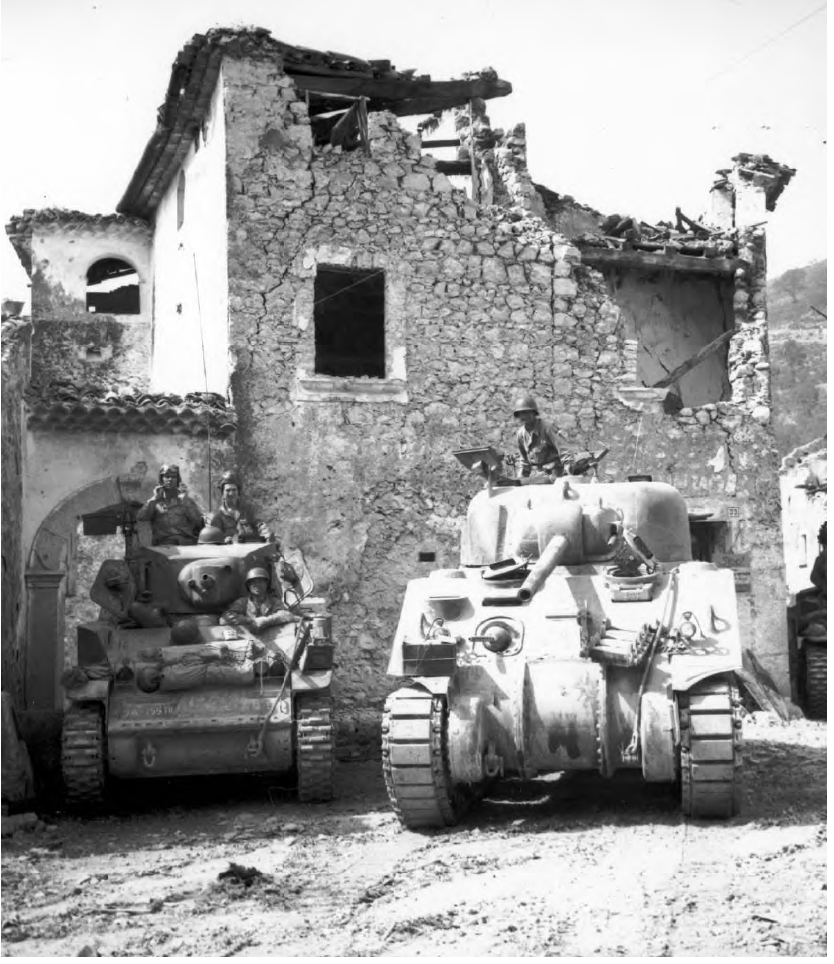

The report was put together in early 44 to document feedback from the troops on current weapons, and proposed improvements, and replacements. There is a good amount of information on the M4 medium tank, and US Armor in general. Most of the combat feedback comes from the fighting in Italy, and North Africa.

The report also sheds an interesting light and gives evidence for the view that the US Army didn’t consider the improved early Sherman bad, and only wanted it replaced with something much better. It also gives some interesting insight into the Shermans and what condition they were in when they got to the using units.

Feedback on current equipment and changes.

The first thing is this to note about the Sherman is the first mention of it is praise for the current models. This quote stands out, “No new type is desired unless the improvement in military characteristics is sufficient to warrant the changes and defects in the present standard tanks are avoided.”

They did have a list of improvements they did want either done to the Sherman and to make sure the follow-on model, the T20 series incorporated them.

- They wanted a 76mm gun like the 3-inch gun on the M10. The news of the 76mm M1 series and the new Shermans mounting the gun interested the troops a lot. They brought an M4E6 76mm Sherman to show to the troops.

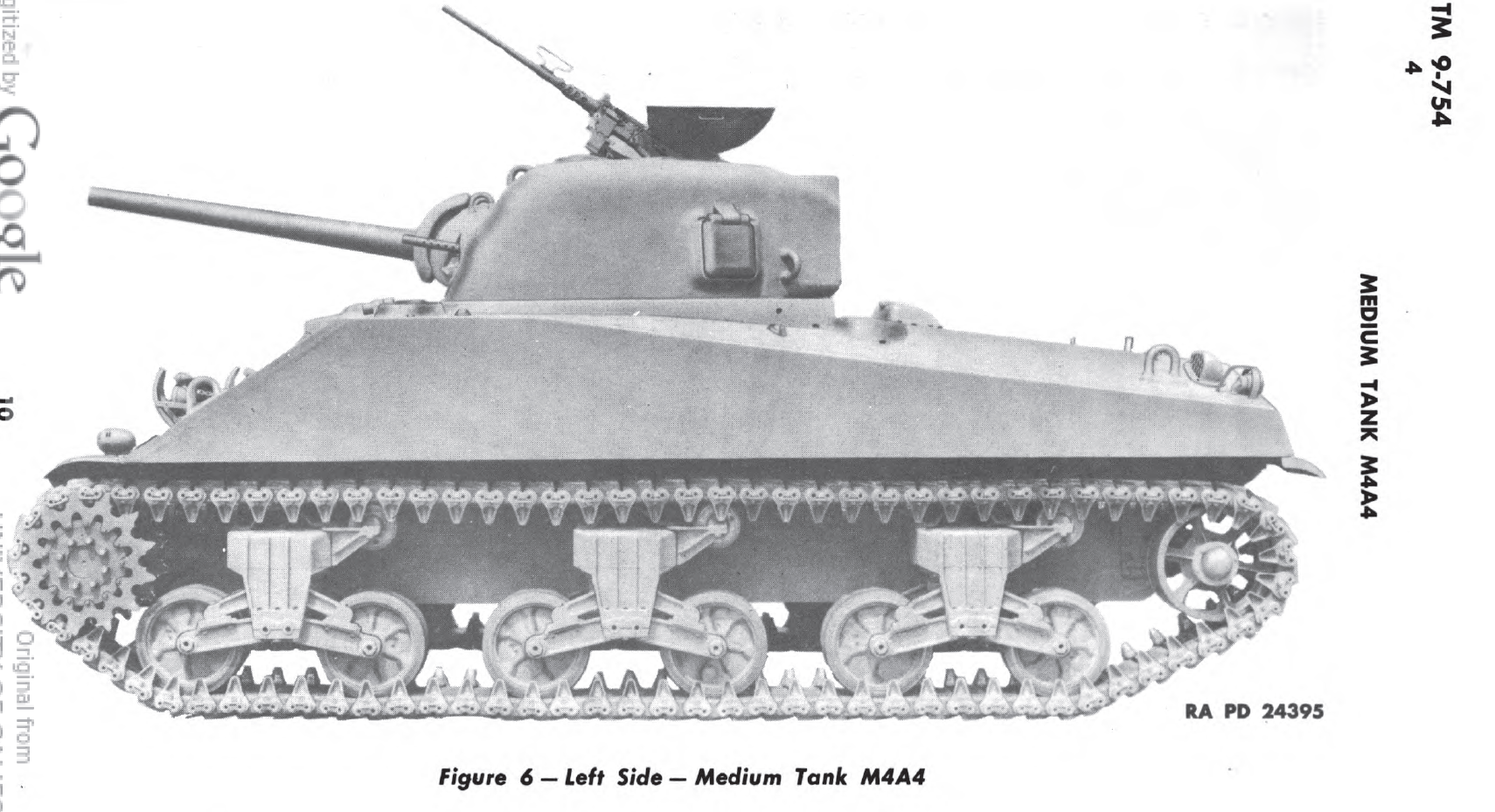

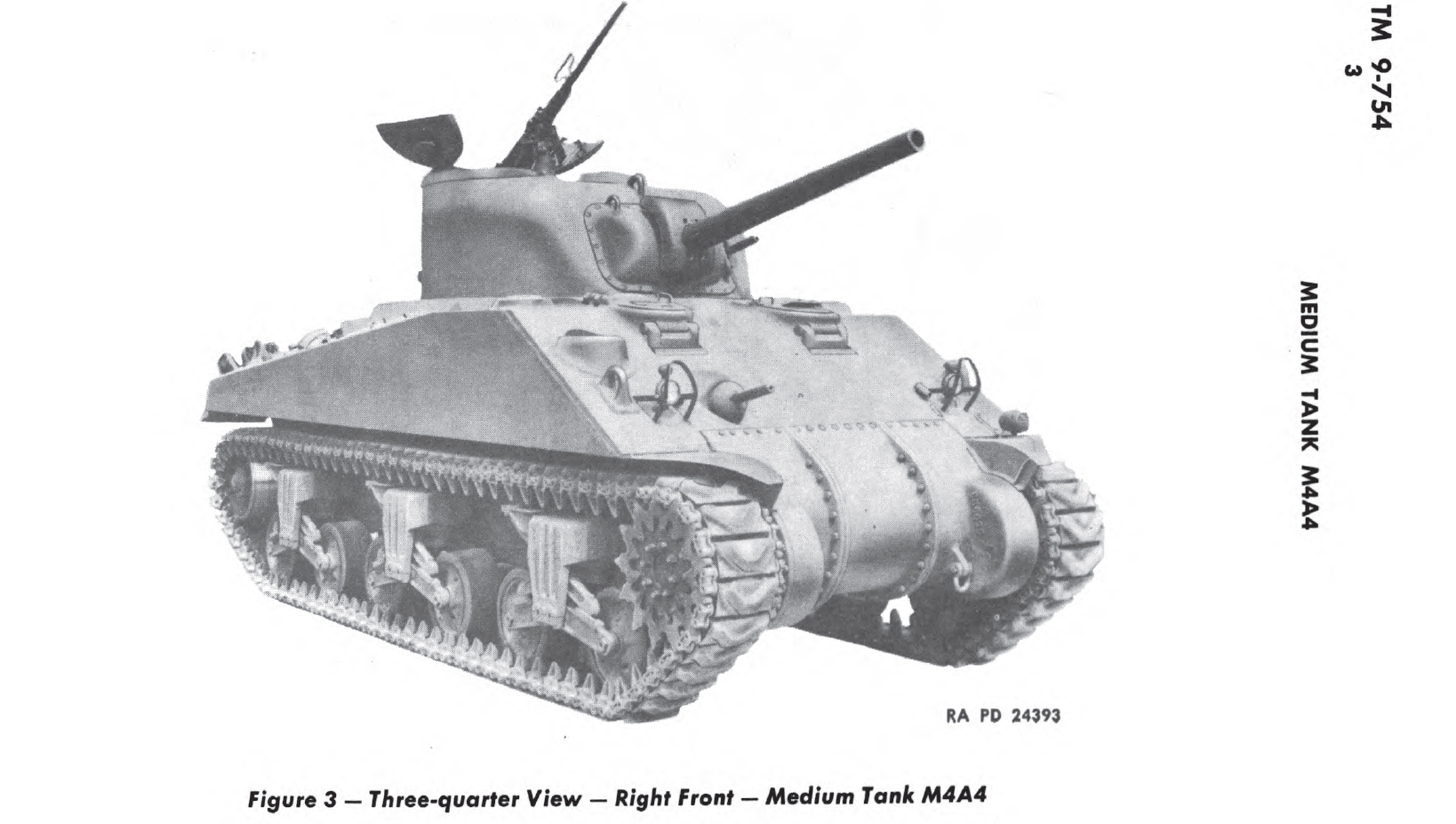

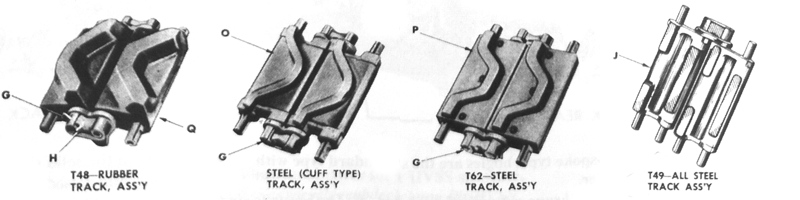

- Improved suspension and tracks. It turns out the rubber block tracks with no chevron were not well liked and wore out very quick in rocky, hilly terrain. The steel chevron blocks with rubber backs were well like and lasted much longer. This feedback is mostly from the MTO, the mountainous and rocky landscape was hard on tanks and even the Sherman had some issues. The complaints about the suspension had more to do with width than durability.

- They wanted armored air cleaners on the M4 and M4A1 tanks. It turns out the Air cleaners mounted under the overhang on the rear hull of the M4 and M4A1 tanks were prone to damage, and this damage was not expected and didn’t pick up until Italy so there was a shortage. All other models had the air cleaners inside the hull. Some units added improvised armor and some were added later in the production runs.

- Better ballistic angle around the front of the transmission housing. The old three-part differential is what they are talking about. Most early Shermans had this type, and the armor was thinner than the later cast single piece units. There were two cast versions, an early thinner, but still no worse than the three-piece unit, and a later improved thicker one. There was a demand for add-on armor over this area, but it was never approved.

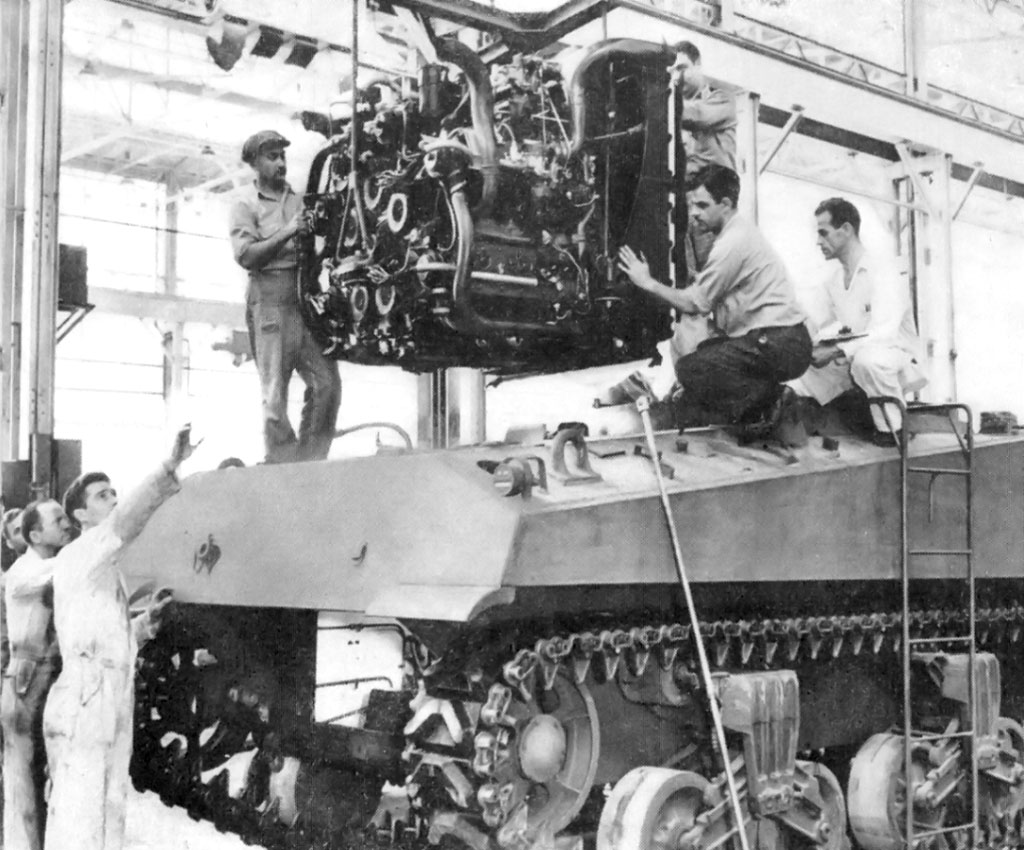

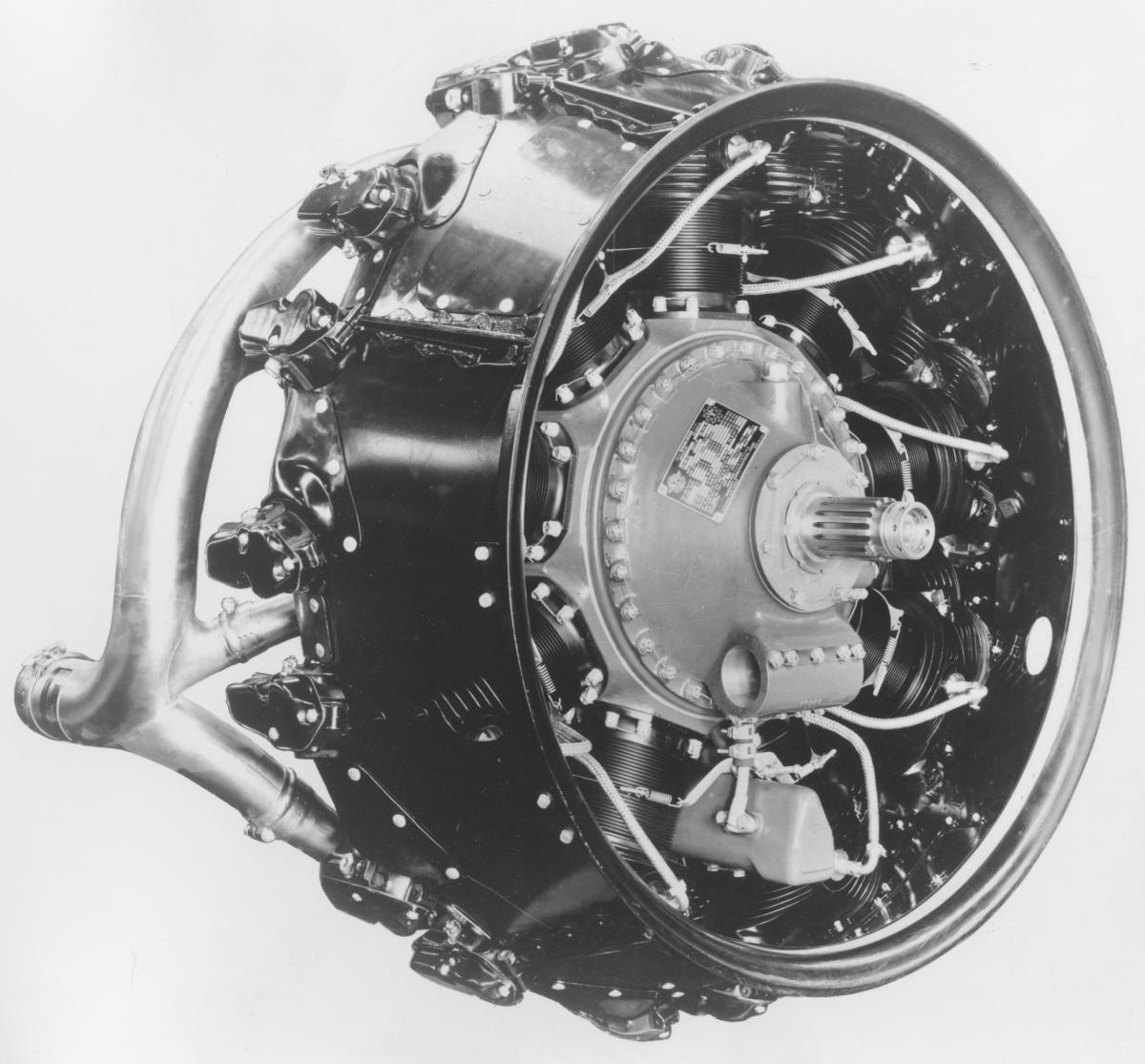

- More power. Yet, when the M4A3 Ford GAA powered Shermans came online, they did not want to swap them in as replacements, and only wanted whole units who trained on them stateside first to be issued the improved tanks. The M4A4 and M4A2 were not big enough improvements to switch to those motors.

- Diesel engine. The US Army rejected the GM 6046, claiming it was not as reliable as the R975, but all the nations that did use this motor liked it.

- They wanted better sights and fire control equipment. Many tanks in the MTO and NATO(North African Theater of Operation) had not gotten the M34A1 gun mounts with telescopic sights. The mount for the periscope sight had not seen major improvements, though there were field mods to make it work. The using arm was enthusiastic about the changes in the second gen Shermans fire control, but wanted even more advanced features, like rangefinders, and improved telescopes, since the current ones shot loose too!

There is also other tank related info.

- The M3 75mm Gun – Though well-liked for infantry support and deemed to be reliable and durable, the using arms almost universally felt the German 75mm PAK 40 guns were much better anti-tank weapons, and a high-velocity 76mm gun was in demand.

- 75mm ammunition – these fixed rounds came unfixed, sometimes even in their travel packaging. They wanted this fixed. They wanted the WP shells ballistics to match the ballistics of the common HE shell.

- Large caliber cartridge cases – Steel cases for the 75mm rounds for the M3 gun were well received and proved more durable. This was not the case for 105mm howitzer rounds.

- 105mm howitzer armed tanks – This was not a popular notion because the M7 105mm GMC was inaccurate when used for direct fire to support infantry assaults. The new weapons board did not agree, and plans for this vehicle were already in motion, and it would be well liked once issued.

- Tank Officers – they wanted a tanker officer in the high-level headquarters to advise Division and higher level officers the best way to use tanks. AA and Tank destroyer officers were already an accepted part of these HQ staffs.

- the 17-pdr gun – There was more interest in using this gun in M10s since the install was much simpler, the Sherman install was complicated and cramped and the Army was leary.

- Tank Tracks – They show up again and the plain rubber block tracks could wear out in 250 miles in rocky terrain and lacked good off-road traction, and the using arm felt they were only good for training on roads. The T54E1 steel chevron type was preferred and much more durable, but the T48 rubber chevron would work in the MTO but wore out faster than steel types. The T49 bar cleat was also not good on sidehill terrain. The using arm wanted a wider center guided track in the MTO because the side guided tracks on the Sherman were prone to throwing on irregular and rocky side slopes. Extended end connectors were well received by the using arms.

- Tank Suspension – Sherman suspension was found to be durable, with few volute springs failing. The biggest problem was the bogie wheels since the rubber tires had an erratic failure rate, and unlike the spring failures, usually sidelined the tank.

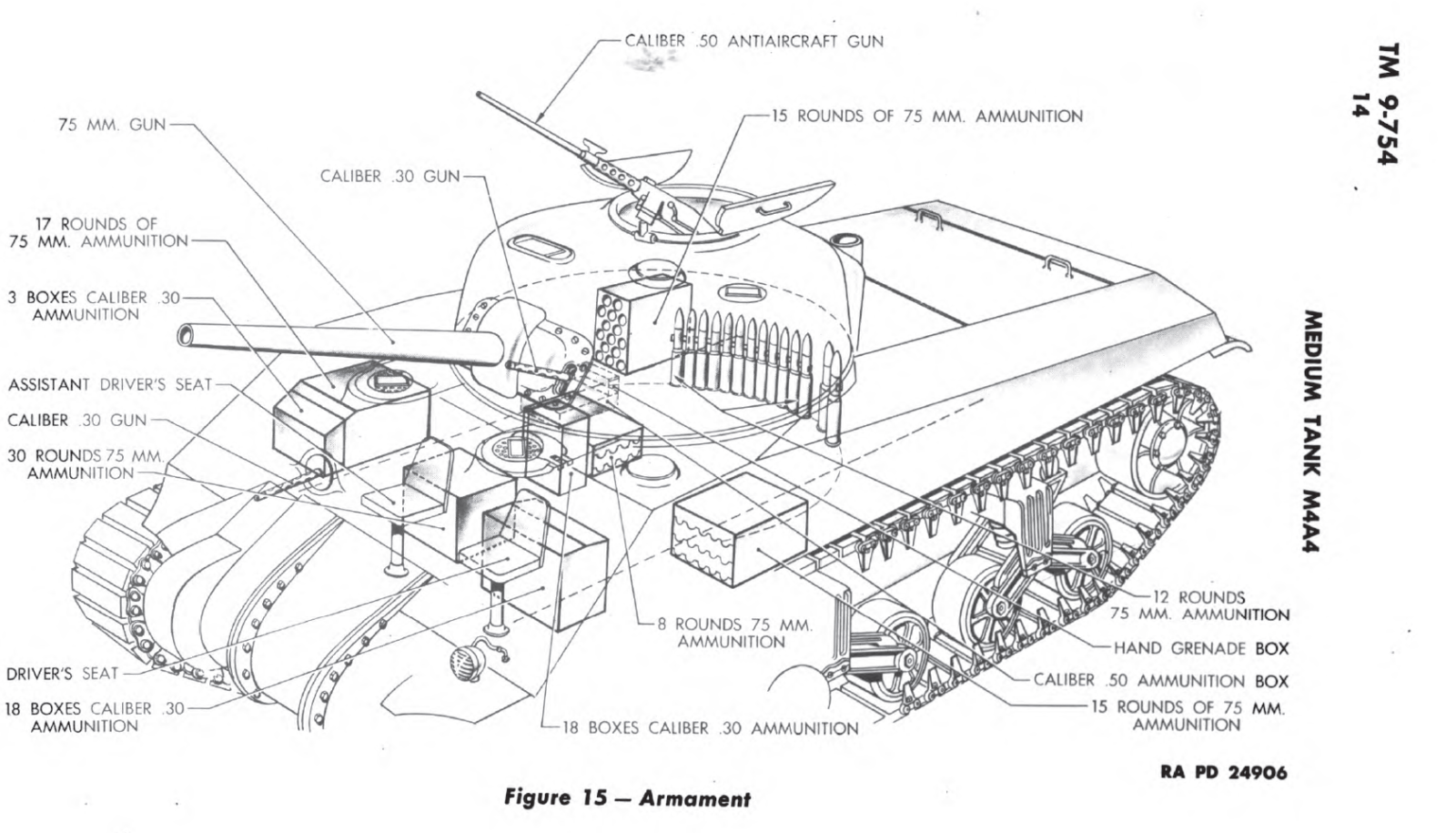

- Ammunition stowage – They using arms were not interested in changes that reduced the number of ready rounds. The turret ready racks were very popular and crews did not like their removal with the ‘quick fix’ mods. They were willing to risk the higher fire chance, for the faster rate of fire the early storage setup allowed. The crews did not get their way on this one, at least until the M26 went into production.

- The Radios – They wanted a better radio in the M32 recovery vehicles and better, more comfortable headphones for the armor crews.

- The M10 GMC – This TD was very popular, and received high praise all around. The using arm did not require a replacement, just improved M10s. ♠ One thing to note, most M10 GMCs in MTO lacked the Azimuth indicator and range quadrant. Since the M10s get used as artillery a lot in the MTO, they would like replacements to have them.

- Replacement gun tubes – The using arms were very annoyed, that all type of gun barrels from machine gun and mortar, to tank and artillery, were dispensed at a very miserly rate. The using arm argued replacement barrels should be bought at the rate that took into consideration how much ammunition for the same weapon was produced.

- Improved fire control for all relevant vehicles – They wanted built-in rangefinders, or portable ones supplied. Better periscope and telescope sights and all vehicles that could be used for indirect fire to receive the full suite of tools to perform the task. I had never heard that some Shermans did not get these automatically. I’m not sure why some Shermans and TDs didn’t have the Azimuth indicator M19 and elevation quadrant M9. Maybe the crews dumped them to save space, maybe the tanks were rushed and built and approved without them I’ll try and find out. They mention 75% of the tanks in England had these items, but less 50% had them in the MTO. Tank units were much more commonly used for indirect fire in the MTO than they would be in the ETO.

- Engines – The R975C-1 was getting around 200 hours before needing replacement.

This was fine with the using arm, though they would like 60 to 100 more horsepower. The R975 needed little maintenance to reach the expected 200 hours and many run much longer. The lack of liquid cooling system has some advantages.

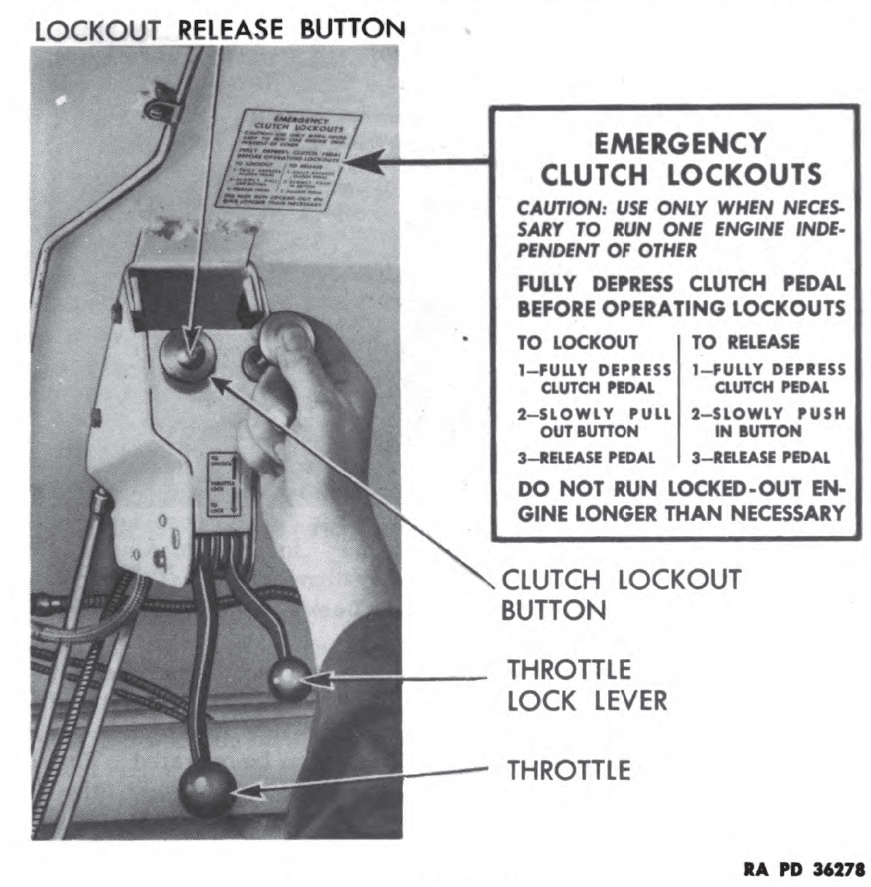

This was fine with the using arm, though they would like 60 to 100 more horsepower. The R975 needed little maintenance to reach the expected 200 hours and many run much longer. The lack of liquid cooling system has some advantages. - Powertrain – There was a higher than expected rate of clutch failure in the desert campaigns. The clutch system was also improved on the production like with improved leverage to lower the clutch pedal pressure. Many MTO units did not receive the improved clutches or linkages. The better clutches lead to better transmission life and better shifting, and even without the improved clutches, transmission life went up in Italy. The powertrain offered excellent service and generally outlived the engines by several overhauls if not damaged.

- Crew comfort – the Driver and Co-drivers seats in the Sherman were found to be ok, but higher seat backs were requested along with deeper seat cushions. The Gunners seat was found to be ok but could use the same improvements as the driver’s seats but the Command and Loaders seats were deemed all but useless. These would be improved in the later models of the Sherman and various TDs. Crews do not use their seatbelts, fearing it complicating bailing out, and more padding inside was not wanted because the crews felt it was a fire hazard. The M4 and M4A1 tanks were praised for good ventilation. There was also some discussion about the value of turret baskets, and if they were needed at all.

- Ammo Storage – The early Sherman ready racks in the turret were well liked by the using arms, but they felt the sponson and hull ammo racks were no good and didn’t support the 75mm Shells enough. They would often separate and dump a bunch of gunpowder inside the tank making a deadly mess to clean. The using arm tends to stuff the tank with extra rounds, adding to the shell durability problems. These problems would be addressed in the second gen improved hull tanks.

- General storage – The current storage space on the Sherman was deemed ok, but better, easier to access bins were requested. They also wanted any storage in the floor to be resistant to getting filled with dirt or water.

- Machine guns – The bow machine gun saw a lot of use, but its usefulness would be improved by a sighting system. One was in the works, but not at the point of this report. The M1919 machine guns, both bow, and co-ax were reliable as long as the crew was careful with the ammo. Long road trips could vibrate rounds loose in the belts and cause problems, but under normal conditions, this was rarely a problem with well-trained crews. The crews wanted a better adjustment method for matching the co-ax gun to the gunner’s site, the current one was not very good. The .50 AA mount was not well liked or considered important. Requests were made for a better mount for ground targets.

- Turret hatches – The current split hatch was deemed ok, but the crews like the looks of the new all around cupola and were also enthusiastic about a loader’s hatch on the new 76 armed tanks.

- Armor – There does not seem to be a consensus on how much armor a tank should have by the using arms. Armored Force troops felt the current level on the Sherman was fine, but wouldn’t mind more as long as it did not negatively affect flotation, maneuverability, and speed. ♠The British generally wanted heavier armor than the US Army. ♠♠Combat in Italy showed the differential was taking more hits than anything, and another request was made for add-on armor for the area.

- Sand Shields – The general consensus on these was they were useless in any theatre and needed to be redesigned. They needed to be easier to install, and designed to not trap mud.

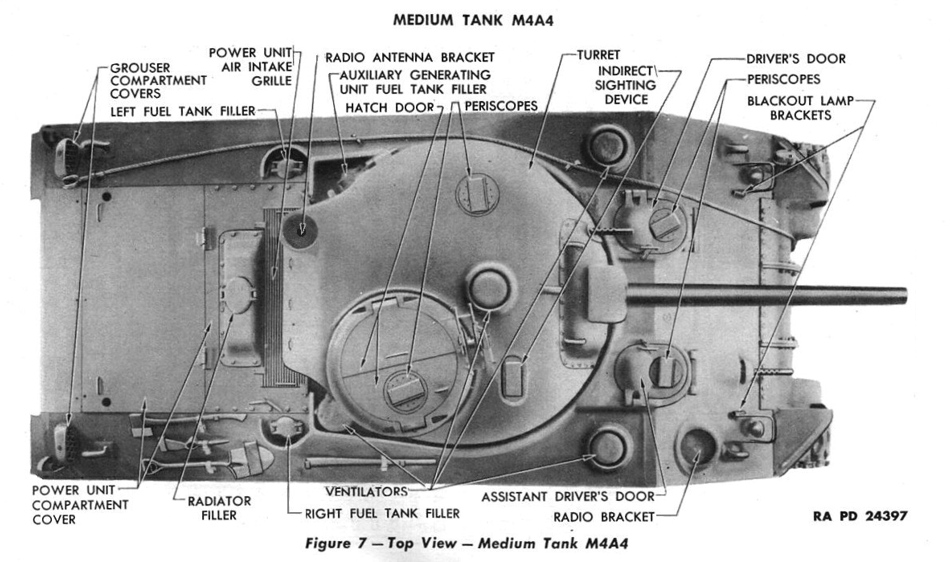

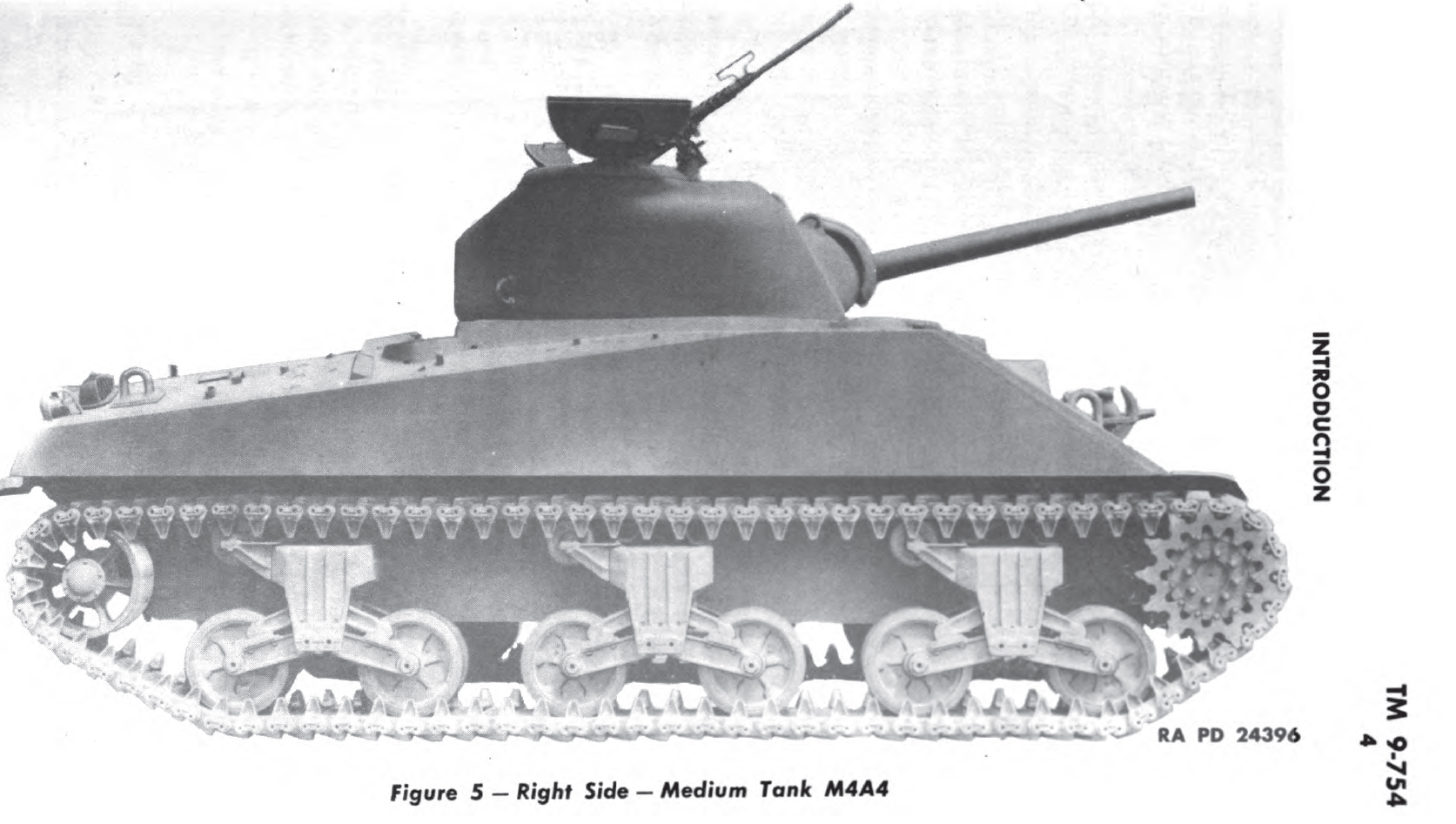

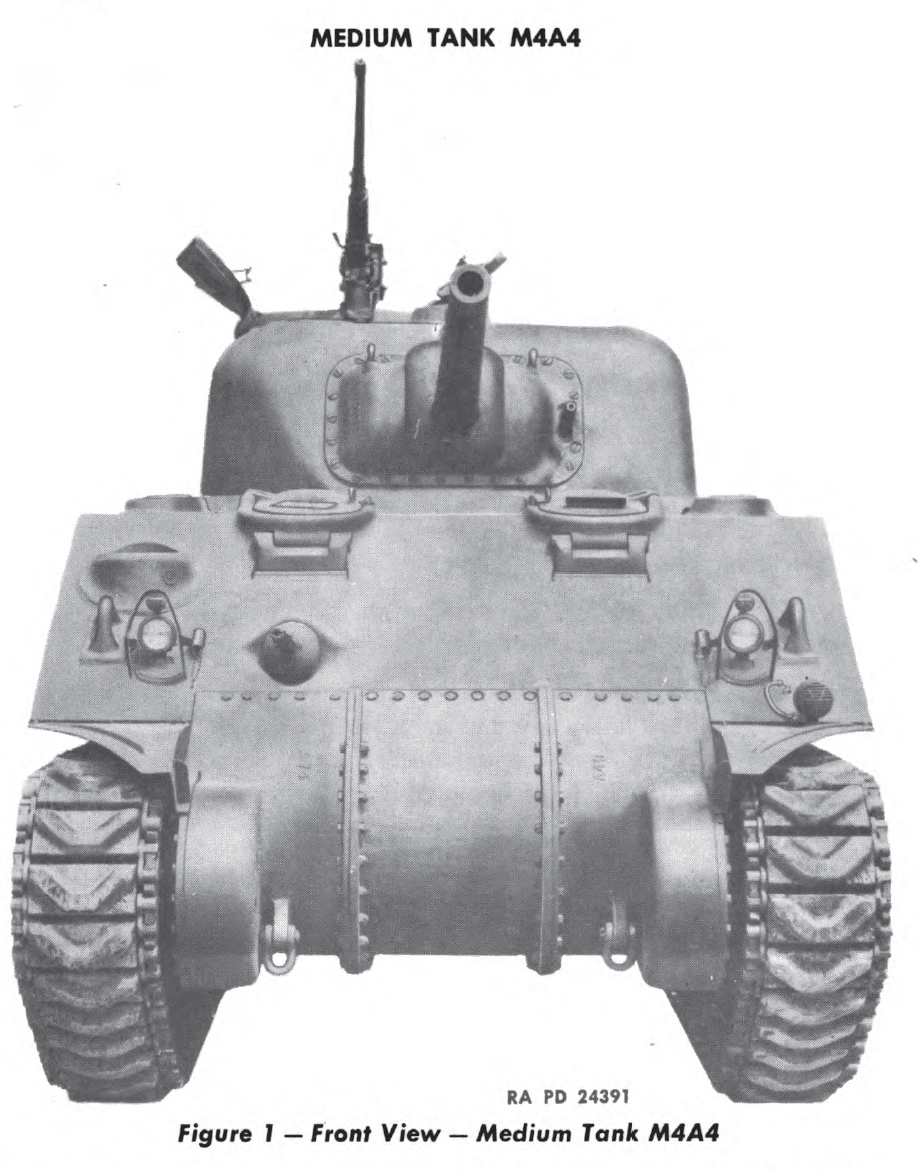

- Flotation – The using arms wanting tanks around 10 pounds per square inch. This was very optimistic since even the HVSS Shermans came in around 11 PSI, the basic 75 VVSS Sherman around 13. It seems the Germans flooded fields in Sicily and Italy when they retreated, and Shermans got bogged down most of the time. They offered the suggestion of just stretching the Sherman since more length would help, and the British M4A4 tanks, the longest production Shermans, had no maneuverability issues.

- Maneuverability – In the US Army there was a desire across the board for more maneuverability, in tanks. One thing to keep in mind though is the tanks in the MTO were older and most had single anchor steering brakes, the double anchor made the tanks easier to maneuver requiring less lever pressure. The ability to skid turn was not something US troops seemed interested in.

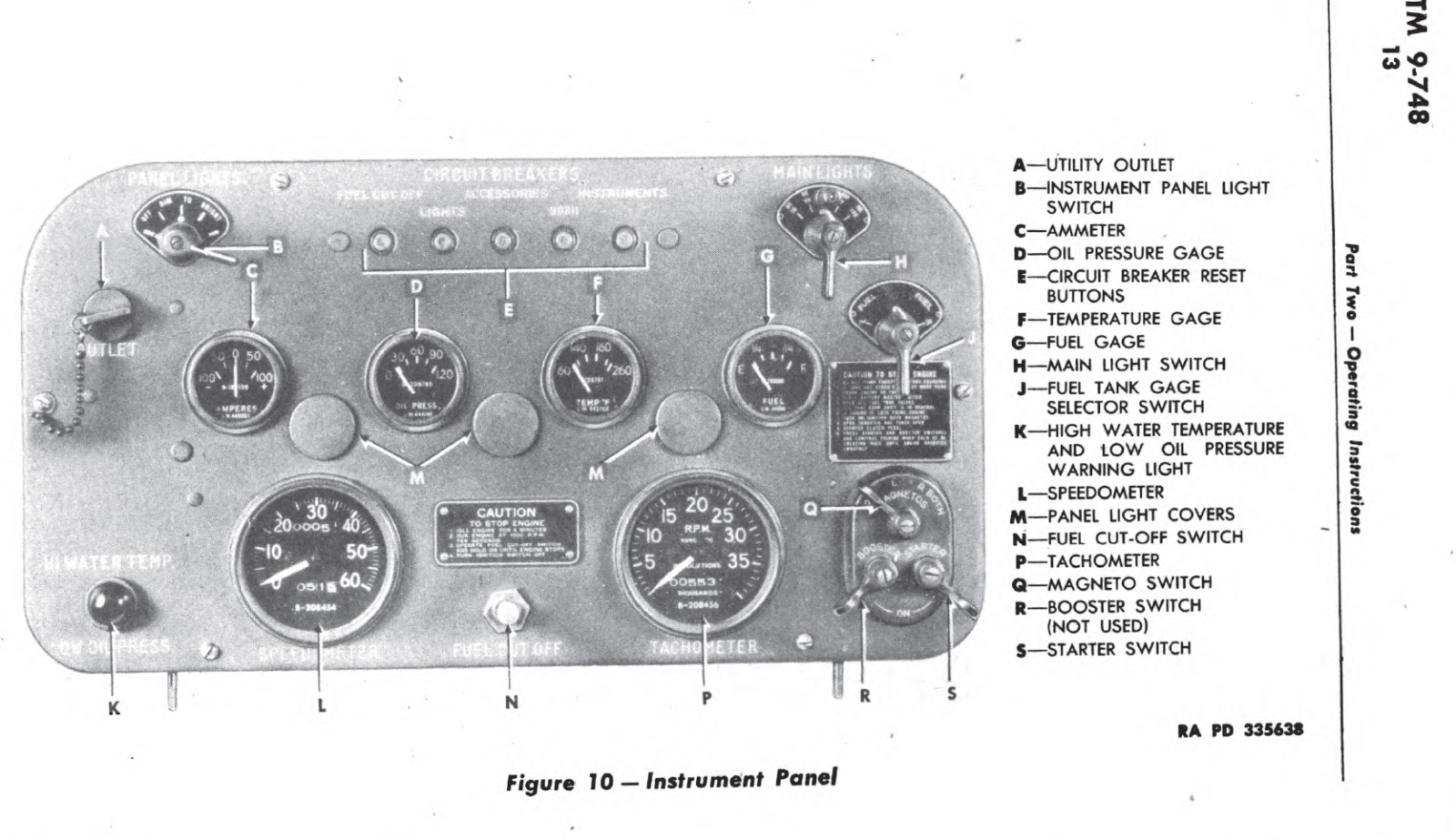

- Accessories – The troops had a lot of feedback here. ♠ The instruments and gauges in medium tanks were not good quality, if they worked they didn’t work long. Oil pressure gauges fail, and no one worries about the motor until both oil pressure gauges die and a low oil pressure light comes on. This seems to be US feedback, I don’t recall hearing complaints from the Brits about Gauge quality. I wonder if the different tank plants sourced gauges from different companies. ♠♠ The compasses on US tanks would not stay calibrated. This would be a very annoying problem but eventually solved on second gen Shermans. ♠♠♠ Armor for the air cleaners on the M4 and M4A1 comes up again. ♠♠♠♠ The Auxiliary giving good service, and are well liked, but the using arms would like the area around the fuel tank filler for the Aux motor to be waterproofed better. They also noted replacements were hard to come by.

- Modifications – ♠ The jist on this one was, in many cases modifications can be seen by inspecting a vehicle, but in others, access panels or more might have to be removed to check. The using arms proposed a record imprinted on a brass plate, attached to the vehicle, listing all the modifications that had been applied. ♠♠ They also wanted to emphasize that they did not want any modifications that would not ‘materially increase the efficiency of the vehicles’

- Development – The using arms were curious about the items in development, and finding out a large organization was working to improve almost everything was a morale booster. There was also interest in the T-20 series and if any test vehicles would be sent over for some for feedback like the M4A1 prototype has been.

Information and feedback on future equipment.

- The M4E6 or pre-production M4A1 76w – ♠ This improved version was well liked by everyone who checked it out. The bigger turret was a big hit, though not much bigger, it seemed roomier. ♠♠ The improved fire control gear was very well liked and considered an ‘outstanding improvement’. The 76mm gun was well liked, and everyone seemed to agree needed. ♠♠♠ The only real concern was the less effective HE round, but it was hoped they would make a better one.

- The M18 76mm GMC – The first and bad impression this vehicle lefts was it had no armor, and seemed very mechanically complicated. The fire control gear was well liked. When the vehicle was demonstrated, the tracks and unthrowable tracks also got a lot of attention. No one was sure if the speed would be useful, but the maneuverability was well liked. ♠ The same story with interest in deployment, not as a replacement vehicle, but fulling trained units from the ZI would be ok. ♠♠ This vehicle was not wanted by M10 units already deployed. Units equipped with it in the ZI then deployed were better received, the M10 was still more popular. An M10 with a 90mm gun was the preferred replacement.

- M4A3 75W – Even though the Ford GAA was a big improvement, it was not enough of an improvement to take them on as replacement vehicles. They were fine for them to be brought with units already fully trained on them.

- The M1 Dozer blade kit – This kit was an instant hit and would have many uses, including clearing rubble after heavy artillery reduced a strong point. Currently, this has to be done by an unarmored bulldozer and casualties were high. it was hoped they would work well enough to help tanks dig in or SPG prepare a position. ♠ Through testing, they found this kit could be installed on any Sherman tank type.

♠

This report goes into detail in the appendixes listing all the items demonstrated, and where they were demonstrated. They also include data on how many of the various items demonstrated were ordered by the various theatres.

I think it’s pretty clear the MTO was a backwater. The general shortage of spare parts in the MTO and a shortage of personnel to staff the proper echelons of repair and salvage system are also indicators of this. As they got ready for the June of 44 landings, the troops in England would be getting top priority and supplies and spares.

There is a lot of info on other weapons like artillery and small arms, not directly Sherman related and therefore, uncovered here. The report is definitely worth a download and re through. I think it offers a good insight into the thinking involved on not swapping to 76mm armed Shermans before the Normandy landings.